Automatic sorting device for express items

An automatic sorting and driving device technology, applied in the field of logistics, can solve the problems of unfavorable popularization, large floor space, inconvenient movement, etc., and achieve the effects of compact and simple structure, easy movement and low manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

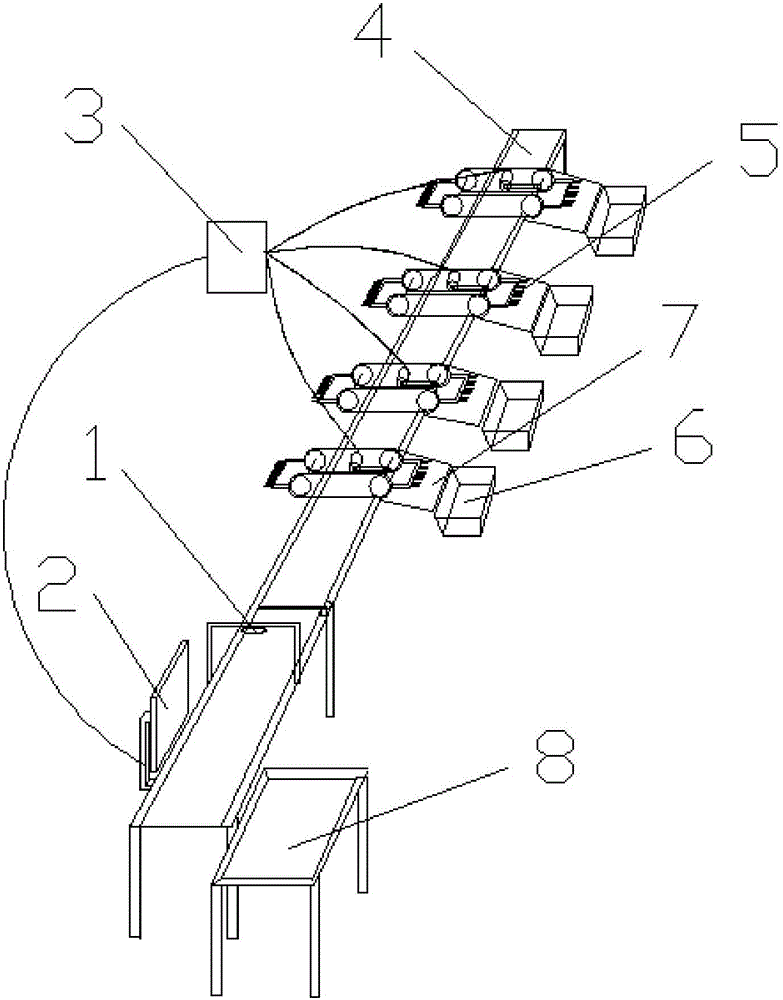

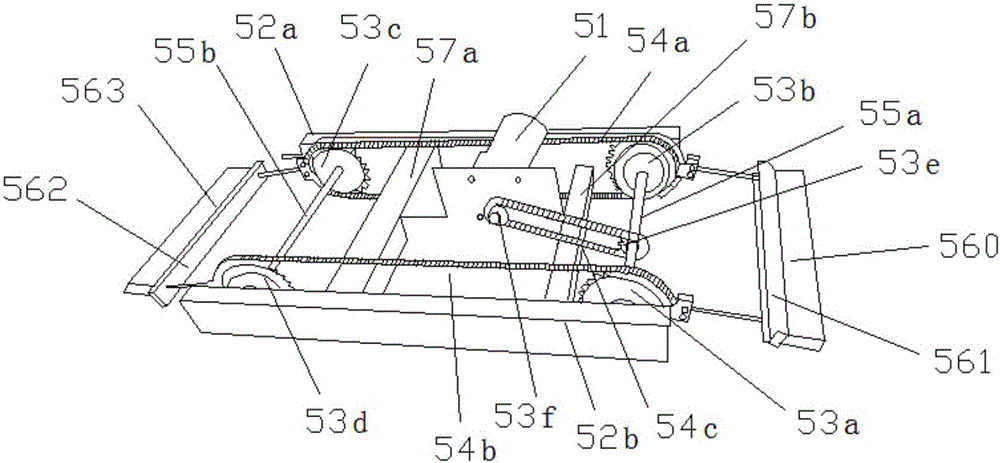

[0027] refer to figure 1 , the present embodiment provides an automatic sorting device for courier items, including an identification code scanner 1, a host computer 2, a lower controller 3, a transmission device 4 and a plurality of action execution units 5;

[0028] The identification code scanner 1 is connected to the upper computer 2, and is used to send the express delivery order number acquired by scanning to the upper computer 2;

[0029] The upper computer 2 is connected with the lower controller 3, and is used to match the corresponding action execution unit 5 after querying the destination corresponding to the courier number, and send the execution command to the lower controller 3;

[0030] The lower controller is connected to each action execution unit 5, and is used to control the actions of the action execution unit 5 after the courier arrives at the matching action execution unit;

[0031] The action execution unit 5 is used to sort the express delivery into th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com