Electromagnetic mechanical gripper device

A technology of mechanical grippers and manipulators, applied in the direction of manipulators, chucks, manufacturing tools, etc., can solve problems such as inefficient actions, unreliable grasping force, and cumbersome control range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

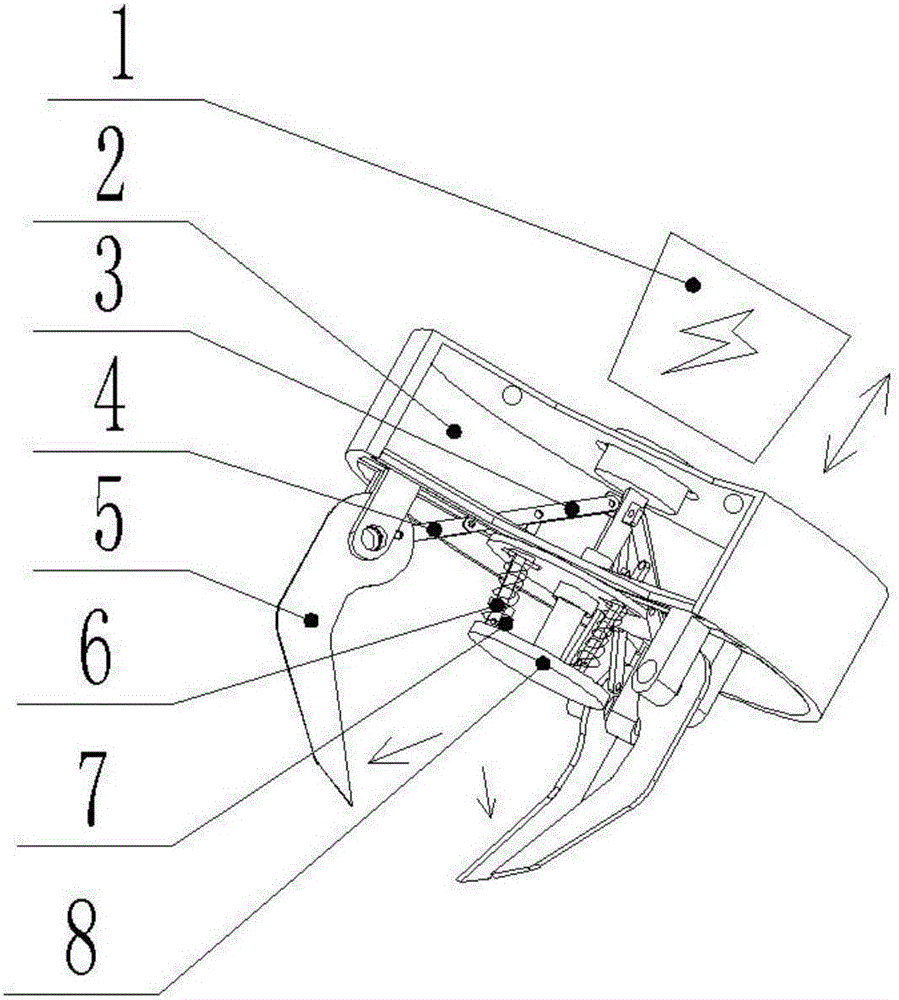

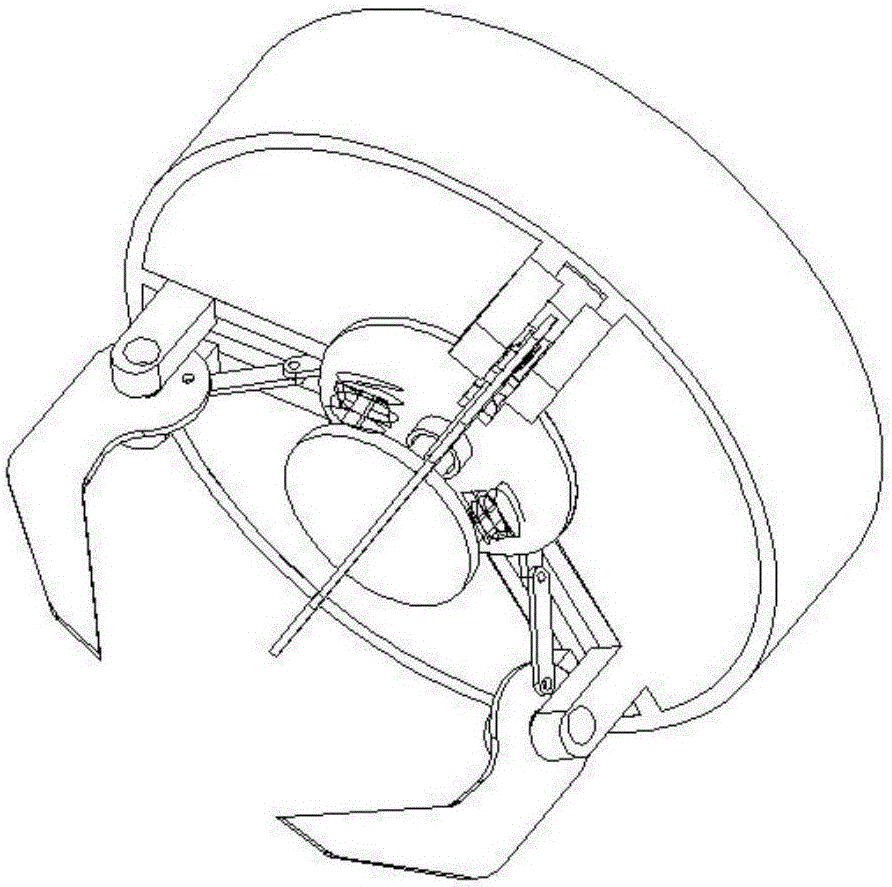

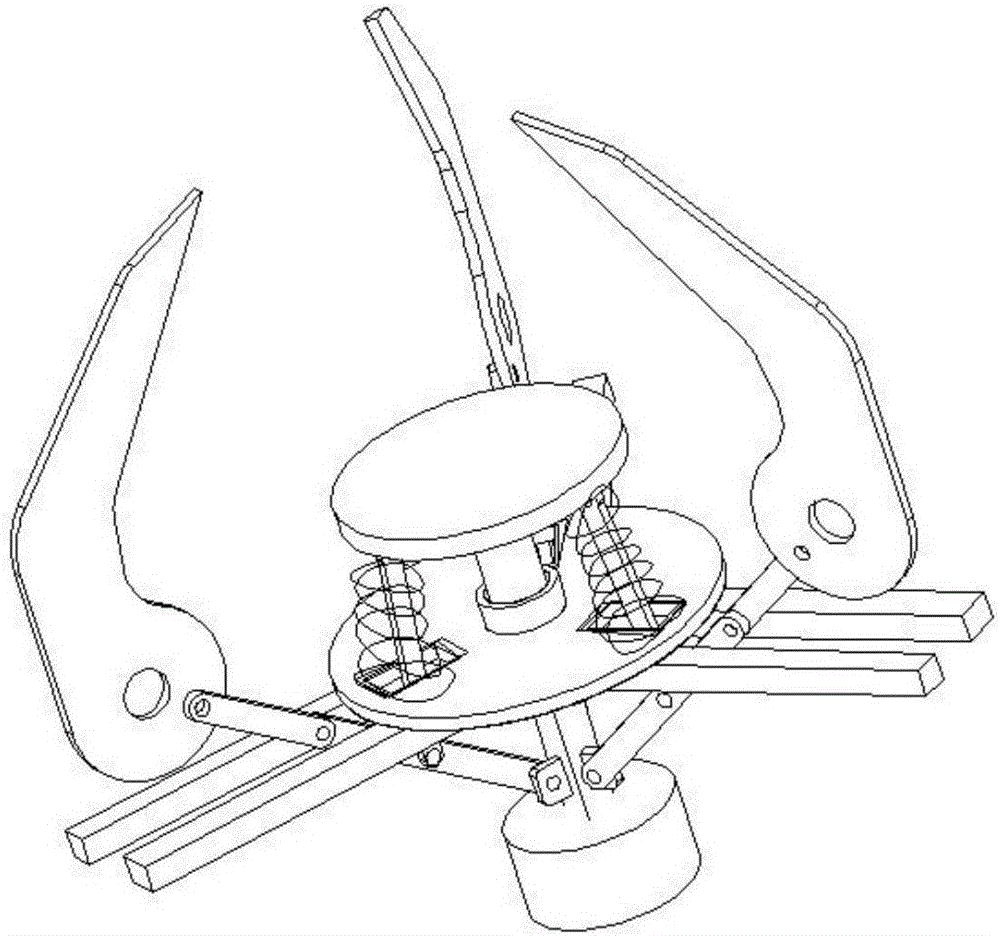

[0008] An electromagnetic mechanical gripper device , is composed of electromagnetic attraction 1, mounting seat 2, support rod 3, crank rocker 4, rotating gripper 5, action connecting rod 6, spring 7, and active rod 8, and is characterized in that: the mounting seat is fixed on the manipulator , the electromagnetic suction 1 is installed on the manipulator and the suction area is aligned with the middle hole of the mounting base 2, the active rod 8 passes through the through hole at the lower end of the mounting base 2, and the upper part of the active rod 8 is a triangular prism with three hinge points. To hinge the three support rods 3, the middle of the support rods 3 is respectively hinged with the action link 6, the action link 6 passes through the mounting seat 2, installs the spring 7 and is respectively hinged on the active rod 8, and the three rotating handles 5 pairs The center is hinged on the mounting base 2, and there are eccentric hinged holes at the joint betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com