A Pose Determination Method of Portal Crane Based on 3D Coordinate Positioning

A portal crane, three-dimensional coordinate technology, applied in the directions of load hanging components, safety devices, transportation and packaging, can solve the problems that cannot be obtained, and has not yet involved determining the position and attitude information of the portal crane, and the method is simple and cost-effective. Low, easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

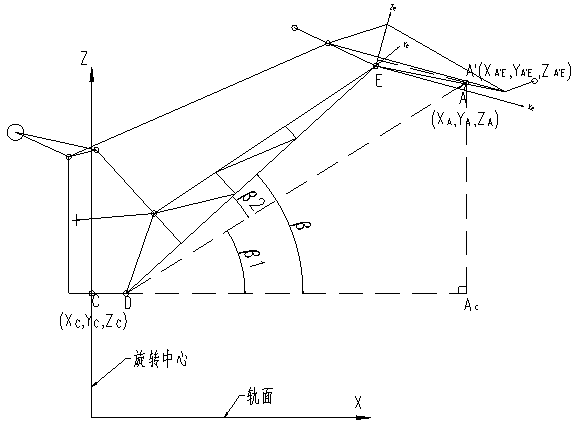

[0028] See attached figure 1 , There are two reference points selected by the present invention, and one reference point is arranged at point A near the center A' of the main hook pulley block at the head of the trunk bridge.

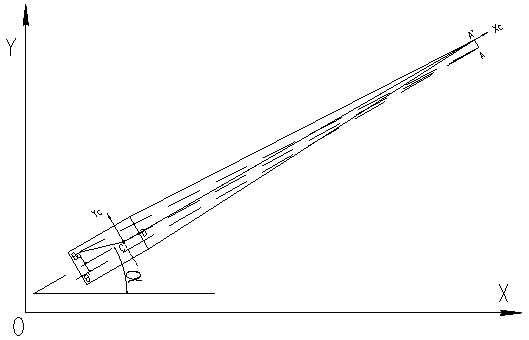

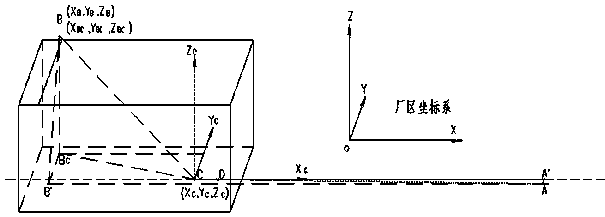

[0029] See attached figure 2 , and another reference point is arranged at point B near the midpoint B' at the rear of the turntable. In the crane luffing plane, point A' is the farthest point from the front of the slewing center, and point B' is the farthest point from the rear of the slewing center. Arranging the measuring points at these two positions can reduce the measurement to the greatest extent. However, when the positioning device is actually installed, due to the limitation of installation space, it cannot be installed on the theoretical point, but can only be installed at a certain position near it, namely point A and point B respectively. The coordinates of point A and point B are measured by three-dimensional coordinate positioning techn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com