Crystallizer and method for crystallization of monoammonium phosphate

A monoammonium phosphate and crystallizer technology, applied in the direction of phosphate, phosphorus oxyacid, etc., can solve the problems of crystal scale agglomerates falling off, crystallizer outlet blockage, etc., and achieve the effect of avoiding crystal scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

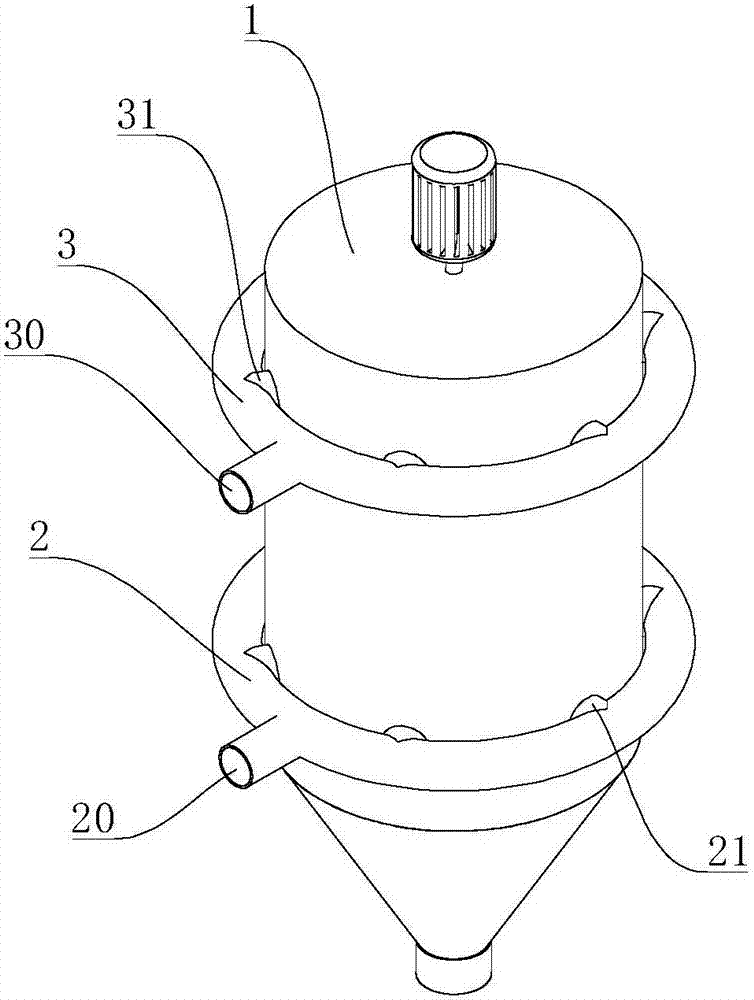

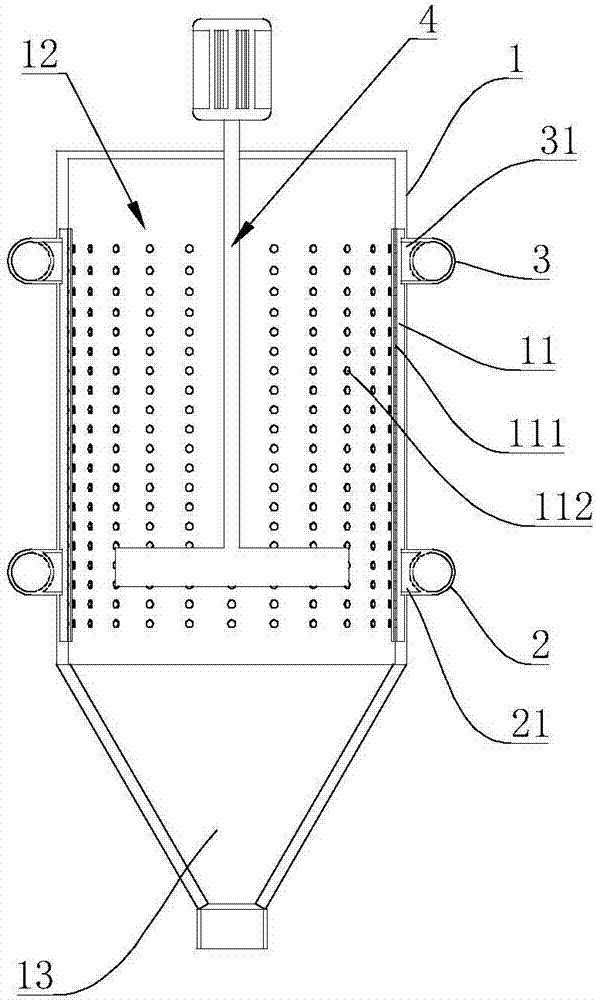

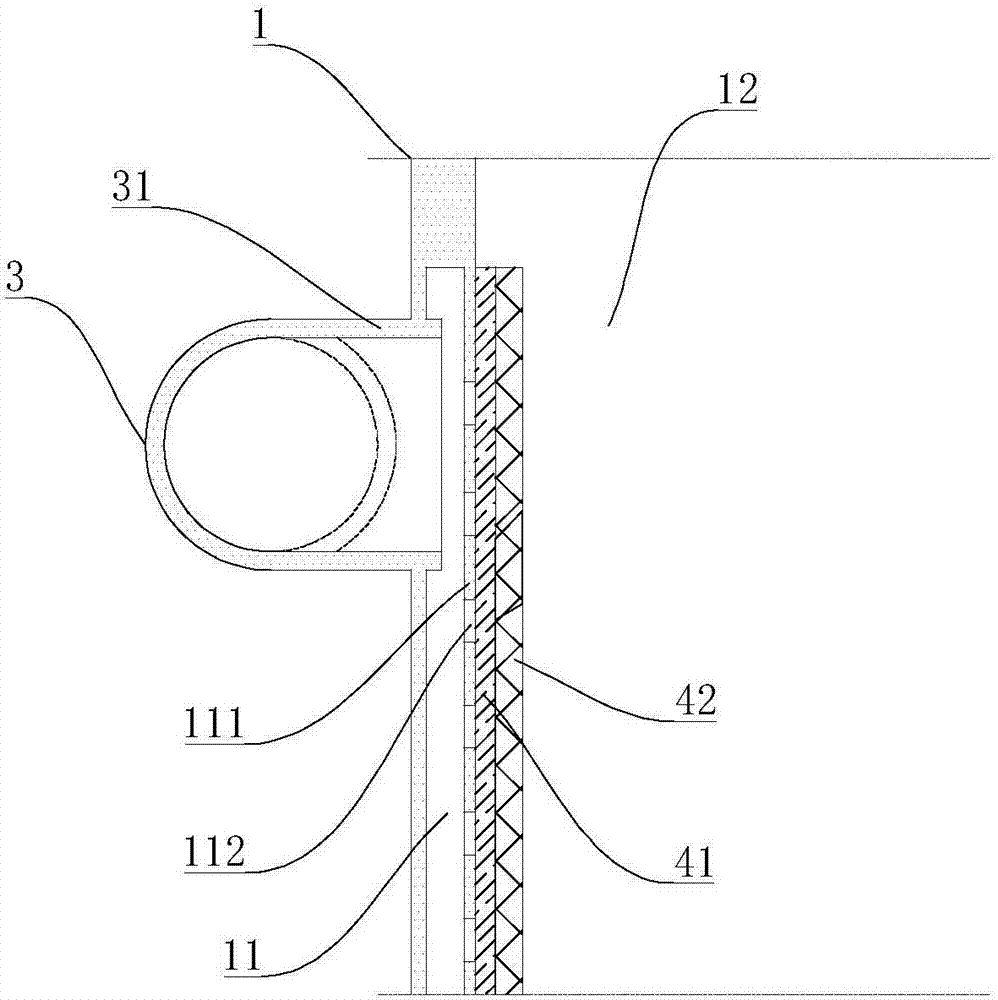

[0027] The crystallizer comprises a crystallizer container 1, the crystallizer container 1 is provided with a feed port and a discharge port, and the inner cavity of the crystallizer container 1 is a crystallizer cavity 12, and it is characterized in that the container of the crystallizer container 1 The wall is provided with a osmotic cavity 11, and the osmotic cavity 11 is connected with a circulating liquid inlet pipe 2 and a circulating liquid outlet pipe 3, and the wall between the crystallizer cavity 12 and the osmotic cavity 11 is a liquid-permeable wall 111, so The liquid-permeable wall 111 is provided with a plurality of liquid-permeable holes 112 , and the liquid-permeable holes 112 are provided with a semi-permeable membrane 41 .

[0028] In this crystallizer, a cavity for storing auxiliary materials is provided on the container wall of the crystallizer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com