Rapid solidification system and method of operation of dredger fill soil for offshore land reclamation

A technology of rapid curing and operation method, applied in soil protection, construction, infrastructure engineering, etc., can solve the problems of uneven curing effect on the surface of the foundation, large changes in curing effect due to local conditions, construction difficulty and strength, etc. The effect of curing engineering cycle, good curing effect and anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

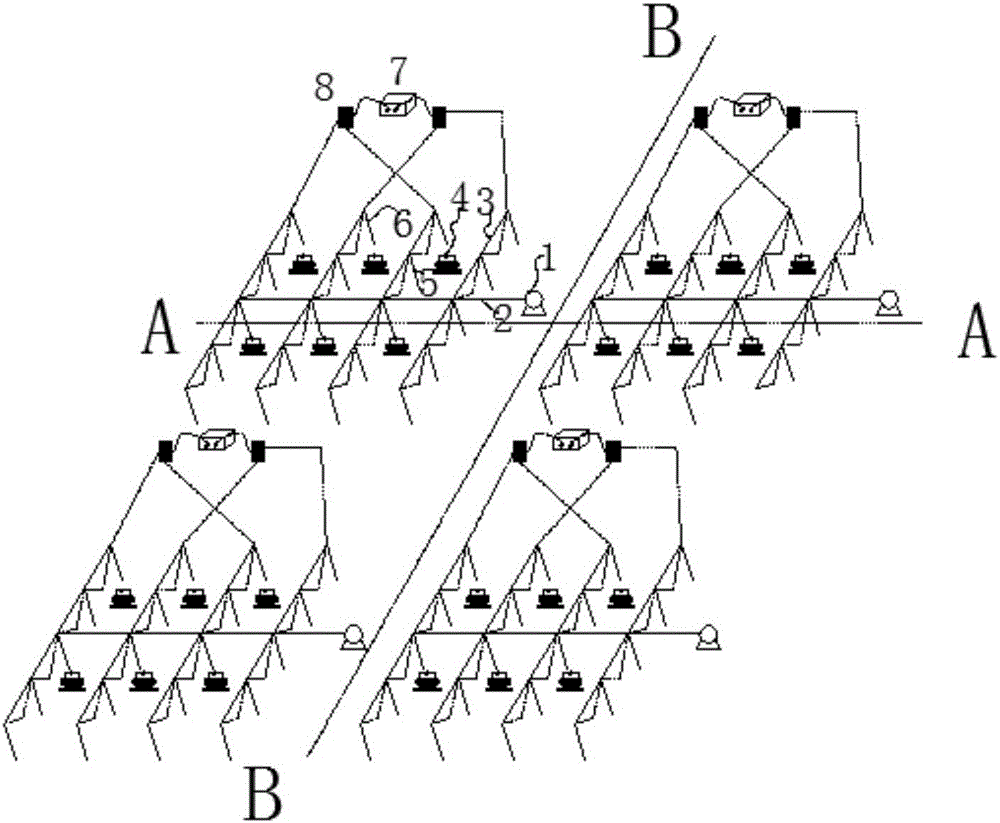

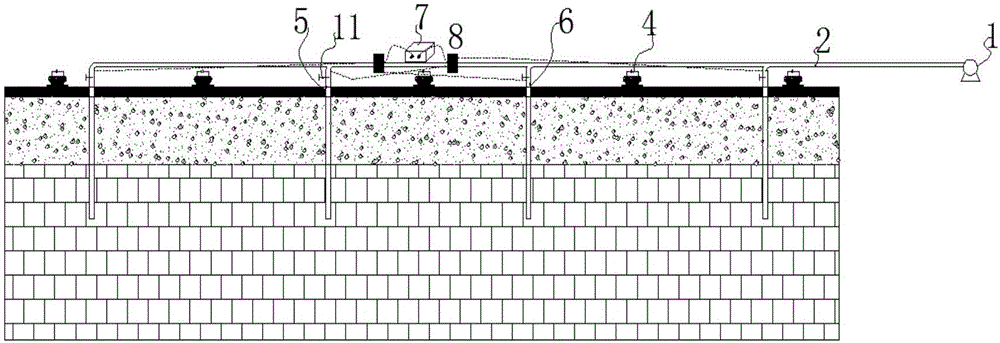

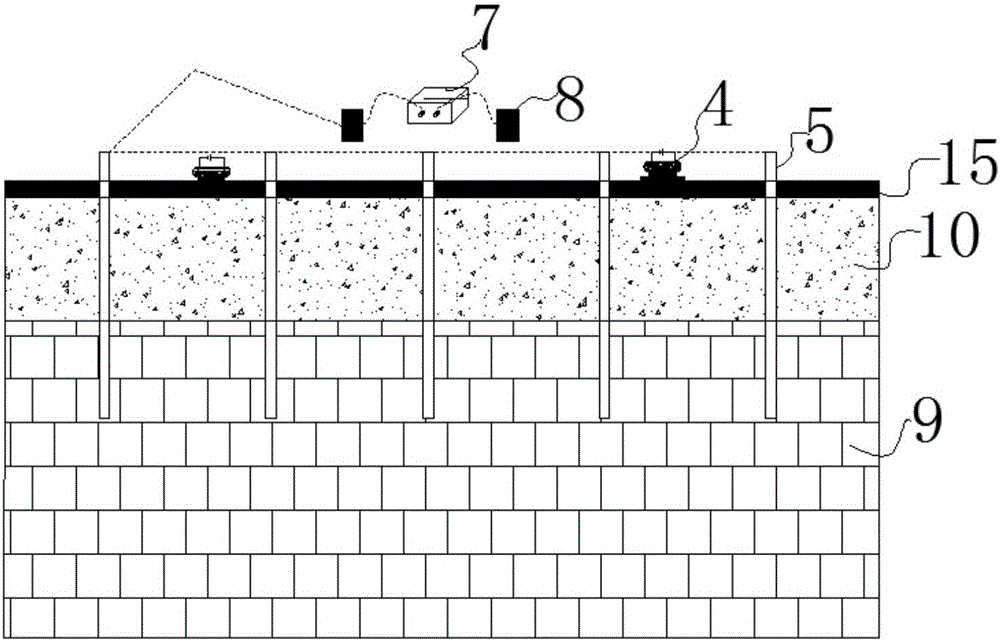

[0035] The vacuum-electroosmosis-dynamic oscillation of the present embodiment strengthens the dredger filling soil solidification system such as figure 1 , figure 2 and image 3 Shown, be to transport the dredging fill 10 by pump at the top of the muddy soil layer foundation 9, the dredging fill thickness reaches 3.5m, and then the sand cushion 15 of medium coarse sand is laid on the dredging fill upper part in the Pingcheng site, height 0.3m, The entire dredging fill area is built with cut-off walls to prevent the flow of dredged fill. Such as Figure 4 As shown, a cutting machine is used to draw a seam on a titanium tube electrode with a diameter of 40 mm. The sealing width of the seam opening 12 is 2 mm, and the distance between the seam is 500 mm. Then, a layer of geotextile 14 is wrapped on the surface of the seam electrode. The wrapped electrode is fixed with iron wire, and then the anode titanium tube 5 and the cathode titanium tube 6 are driven into the dredged la...

Embodiment 2

[0038] The CSSC Longxue Island shipbuilding base in Guangzhou is located on the right bank of the Pearl River outside Humen, on the east coast of the Longxue Island reclamation area. In March 2004, the silt was dredged and filled to a height of 4.3m. In order to finish the solidification of the silt in October 2004, the civil construction was carried out. The construction period was very tight, and the normal solidification and leveling work could not be carried out at all with the mud. Areas 6-13 of the 13 areas in the re-solidification area adopt vacuum-electroosmosis-dynamic oscillation curing projects, with a total curing area of 26,000 square meters.

[0039] First, build a silt retaining wall in the curing area, and then lay vacuum electroosmosis curing equipment. After 14 hours of vacuum electroosmosis, carry out the first dynamic load. The first load can be 800-1000KN m. Level the curing area. Carry out the second vacuum electroosmotic curing for 14 hours, and then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com