Two-stroke engine cylinder closed scavenging passage

A technology of engine cylinder block and scavenging air passage, which is applied to engine components, combustion engines, machines/engines, etc., can solve the problems of inability to completely eliminate compound emissions, unfavorable environmental protection, and excessive storage of gas, so as to reduce losses and improve power. , Improve the effect of scavenging speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 example

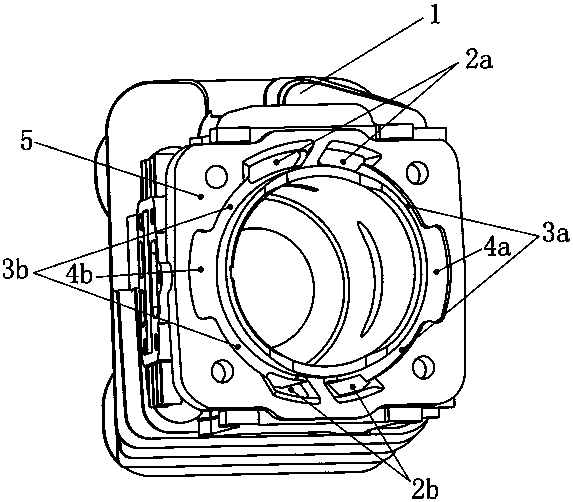

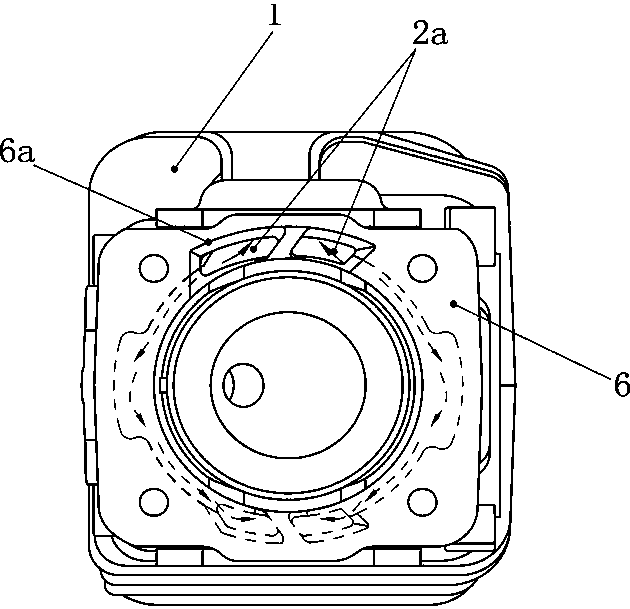

[0025] Second embodiment: when the thin plate 7 covers the flange surface 5 of the cylinder body and the thin plate opening 7b is matched with the closed scavenging passage 2b, the mixed gas in the crankcase enters the closed scavenging passage 2b through the thin plate opening 7b , the other part respectively along the groove channel 3b→expansion channel 4b→groove channel 3b→entering the closed scavenging channel 2a, and along the groove channel 3a→expansion channel 4a→groove channel 3a→entering the closed scavenging channel 2a , and finally enter the cylinder to increase the length of the closed scavenging passage.

no. 3 example

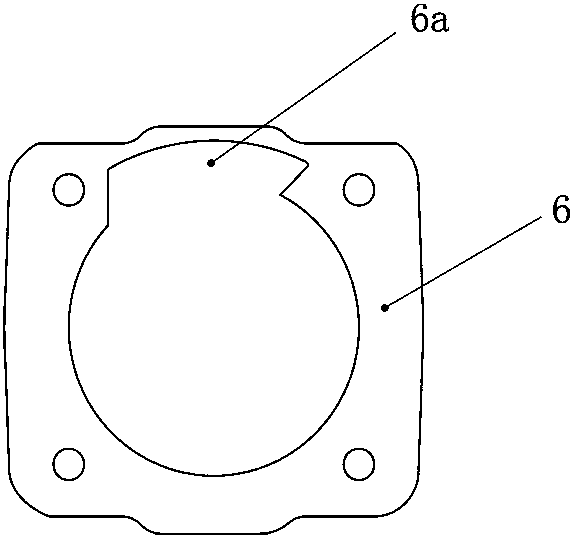

[0026] Third embodiment: when the thin plate 8 covers the flange surface 5 of the cylinder body, and the thin plate openings 8a, 8b are matched with the expansion channels 4a, 4b respectively, a part of the mixed gas in the crankcase enters the thin plate opening 8a and passes through the thin plate opening 8a → Expansion channel 4a → Groove channel 3a → Closed scavenging channel 2a; and through sheet opening 8a → Expansion channel 4a → Groove channel 3a → Closed scavenging channel 2b; another part of the mixture in the crankcase enters the sheet opening 8b, through thin plate opening 8b→expansion channel 4b→groove channel 3b→closed scavenging channel 2a; and through thin plate opening 8b→expanded channel 4b→groove channel 3b→closed scavenging channel 2b. The final mixture enters the cylinder block to increase the length of the closed scavenging path.

[0027] Finally, the mixed gas respectively passes through the closed scavenging passage 2a and the closed scavenging passage ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap