Combustion-supporting device

A combustion aid and bushing technology, applied in solid heating fuel, lighting and heating equipment, household stove/stove, etc., can solve problems such as poor convection effect of thermal field, uneven combustion, uneven combustion in the furnace, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

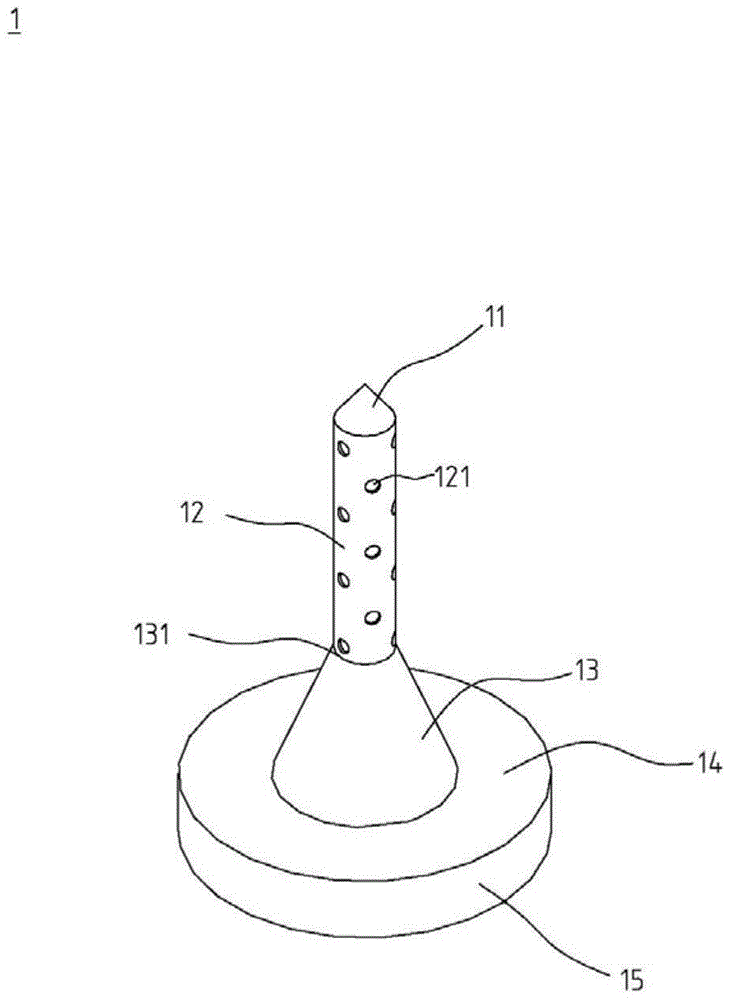

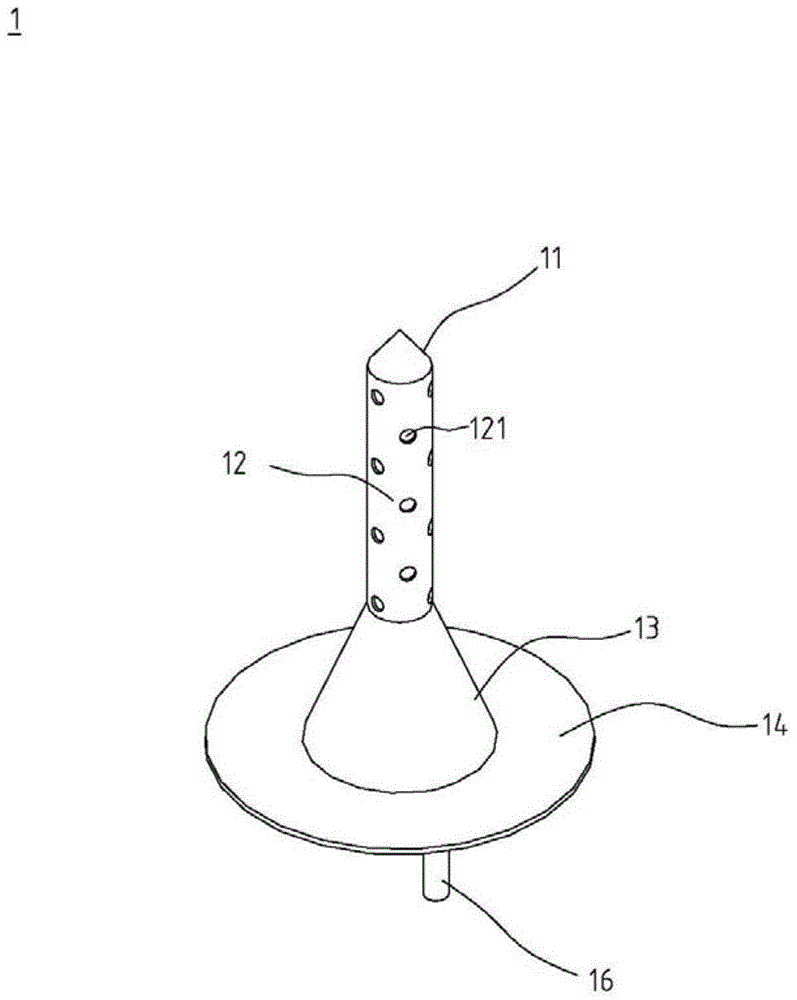

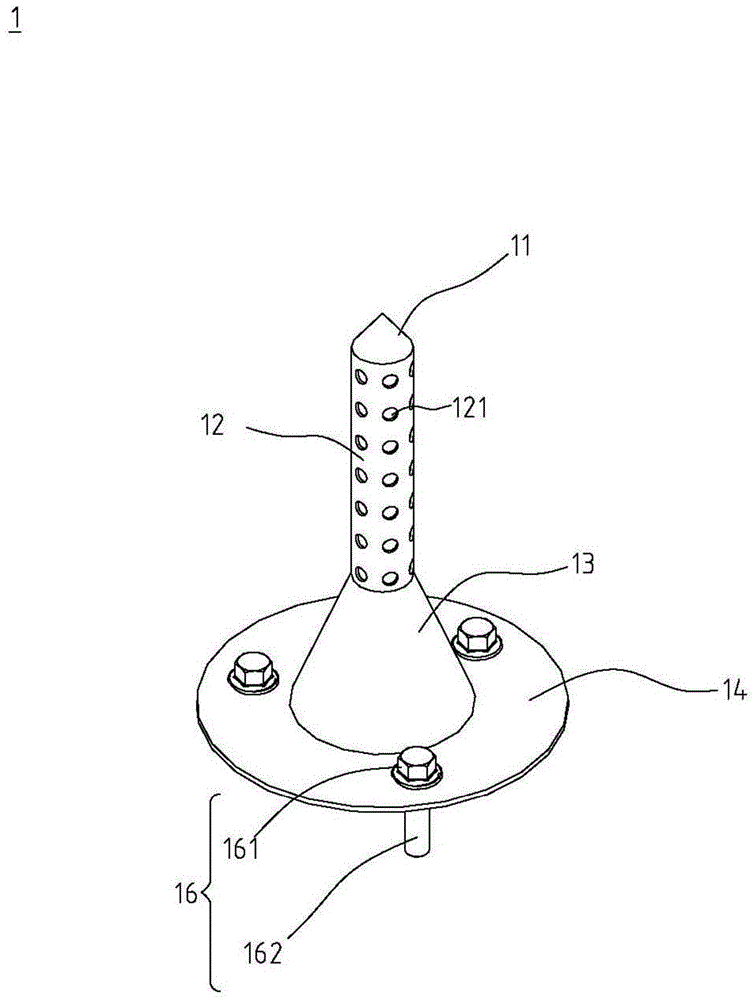

[0037] Please refer to figure 1 , is a schematic perspective view of the first embodiment of the burner 1 of the present invention. The burner 1 is used with a combustion furnace, and includes a cone 11 , a hollow sleeve 12 , a cone-shaped sleeve 13 , a bottom plate 14 and a support portion 15 . The upper end of the hollow sleeve 12 is connected to the cone 11 . The hollow sleeve 12 includes a plurality of air holes 121 , and the air holes 121 are opened on the upper end of the hollow sleeve 12 in a surrounding manner. The tapered sleeve 13 includes an insertion port 131 , the size of which corresponds to the diameter of the hollow sleeve 12 , and the lower end of the hollow sleeve 12 is inserted into the tapered sleeve 13 through the insertion port 131 . Bottom plate 14 comprises hole 141 (please refer to Figure 4 ), the position of the hole 141 corresponds to the hollow sleeve 12, and the bottom plate 14 is connected to the bottom of the conical sleeve 13, wherein the hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com