Method for performing temperature calibration on scene of pipeline leakage monitoring

A pipeline leakage, on-site technology, used in thermometers, thermometer testing/calibration, thermometers with physical/chemical changes, etc., can solve the problems of many attenuation points, large attenuation, and the temperature calibration scheme cannot adapt to the engineering environment, and achieves convenient operation. , the effect of high practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

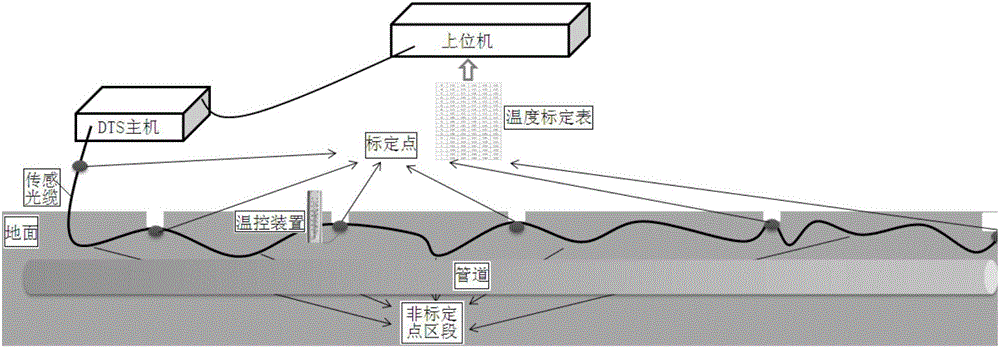

[0024] In this embodiment, a section of 10 km long pipeline is taken as an example to illustrate the method of temperature calibration at the pipeline leakage monitoring site. refer to figure 1 , A sensing optical cable is laid next to the pipeline, one end of the sensing optical cable is connected to the DTS host, and the DTS host communicates with the upper computer. There is also a temperature control device for calibration on site. The DTS host is mainly used for the generation of optical pulse signals, the acquisition and preprocessing of Raman scattering signals, the host computer is mainly used for demodulation and display of temperature information, and the temperature control device is mainly used for on-site calibration points Heating and temperature control.

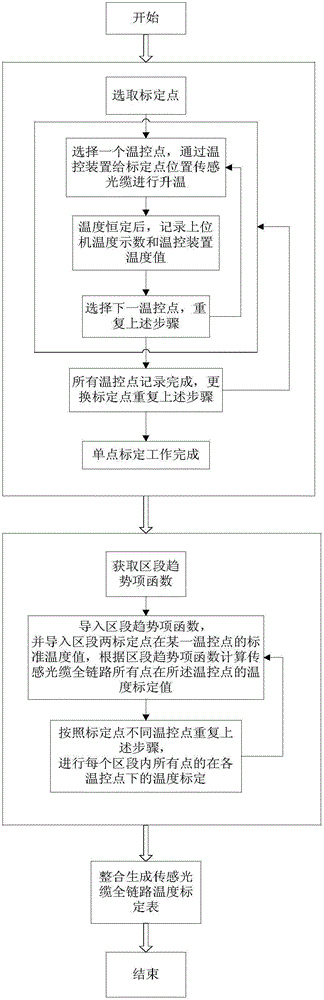

[0025] refer to figure 2 For temperature calibration, proceed as follows:

[0026] S1. Select calibration points on the entire link of the sensing optical cable to be tested, and perform single-point temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com