Strength testing fixture using uniaxial testing machine for variable-proportion biaxial loading

A uniaxial test and fixture technology, applied in the direction of strength characteristics, measuring devices, instruments, etc., can solve the problems of lack of equipment and high test costs, and achieve the effect of saving costs and simplifying the test device.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

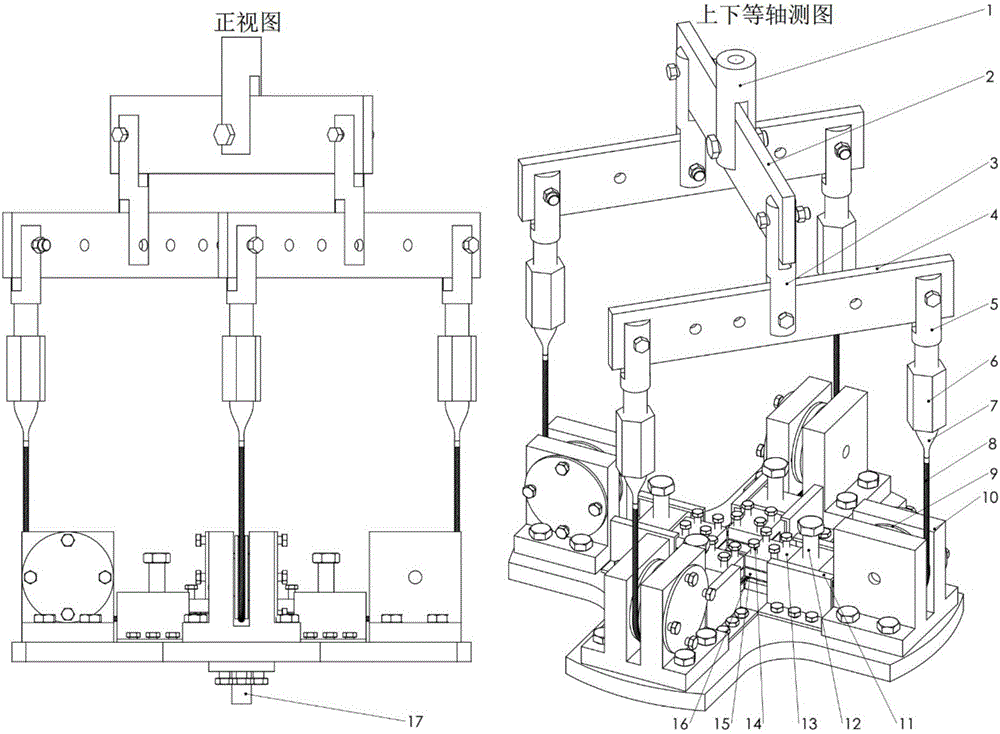

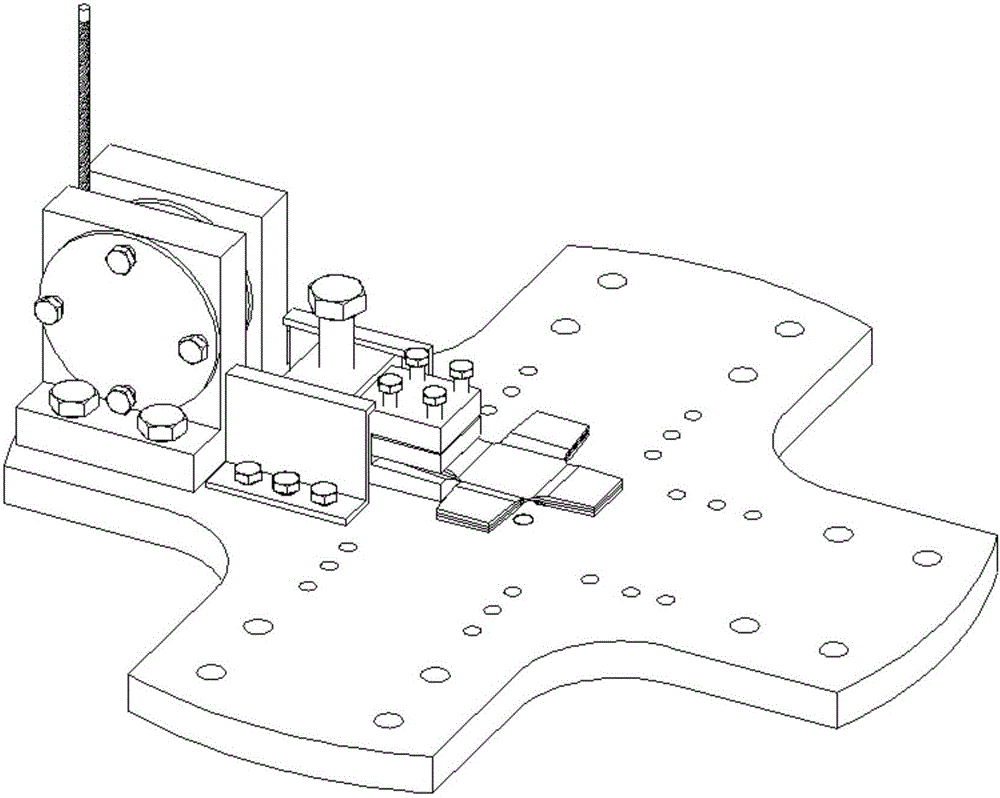

[0044] combine figure 1 with figure 2 Describe the specific use and realization principle of the present invention.

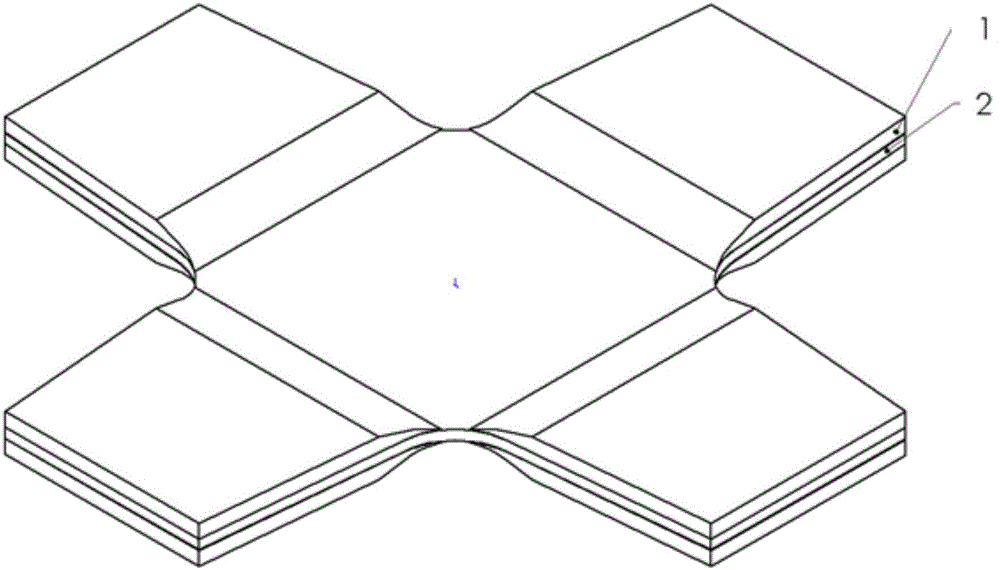

[0045] according to figure 1 with figure 2 Install the fixture and clamp the four ends of the test piece so that the test piece is in the center of the base, and the upper and lower chucks (1 and 17) are respectively connected to the uniaxial testing machine, and according to figure 1 Adjust the elastic nut 6 so that the primary lever and the secondary lever are balanced and in a horizontal position, and the steel wire rope 8 is in a tight state. Start the uniaxial testing machine and load it slowly. At this time, assume that the upward pulling force of the upper chuck on the testing machine is F, then it can be known from the principle of lever balance that the pulling force exerted by the primary connecting rod 3 on the fulcrums of the two secondary lever beams is equal. It is F / 2, and the force analysis of the secondary lever shows that the magnitude o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com