Sensor for on-line detection of tritium content in liquid lead-lithium alloy

A lithium alloy and liquid lead technology, applied in the field of nuclear engineering, can solve problems such as difficult decontamination, high measurement background, long time required for sensor balance, etc., achieve simple detection process, reduce tritium loss and contamination effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

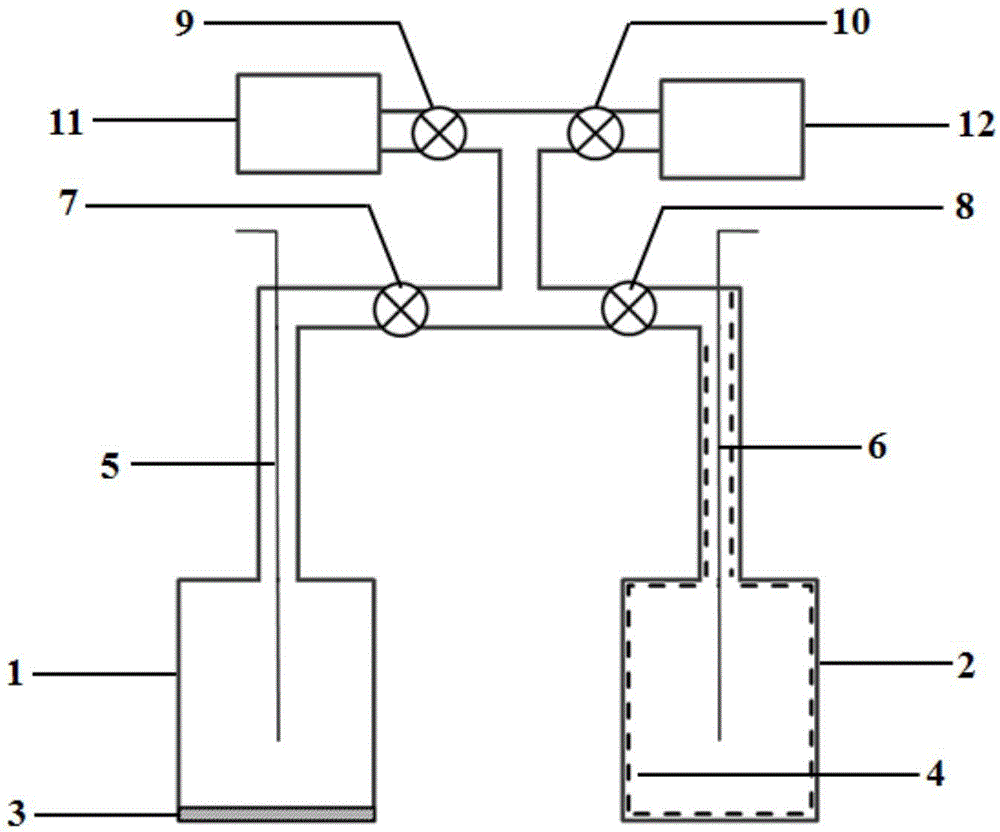

[0027] According to the above description, a sensor for measuring tritium was designed and developed. The structural material of sensor sample chamber 1 is CLAM steel, the tritium permeable membrane on the bottom surface is Nb-Ni-Ti alloy, and the outer wall of the elongated tube at the upper end of sample chamber 1 is covered with Al 2 o 3 Anti-tritium penetration coating; the structural material of reference chamber 2 is CLAM steel with Al on the inner wall 2 o 3 Anti-tritium penetration coating; the working gas in the working gas tank 11 is He gas. The developed sensor probe is first immersed in liquid lead and then taken out, so that the surface is covered with a lead metal protective film to avoid oxidation of the material surface during transportation and storage. The sensor measurement process is as follows:

[0028] (1) Calibrate the sensor to obtain the relationship curve between the tritium content and the measurement count in the sample chamber 1;

[0029] (2) I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com