Novel double-glass solar module and edge sealing method thereof

A solar module, a new type of technology, applied in the direction of electrical components, semiconductor devices, photovoltaic power generation, etc., can solve the problems of burrs on the edge, ugly appearance, and fragile components during transportation, so as to prolong the service life, improve the fragility problem, and save cutting. side process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

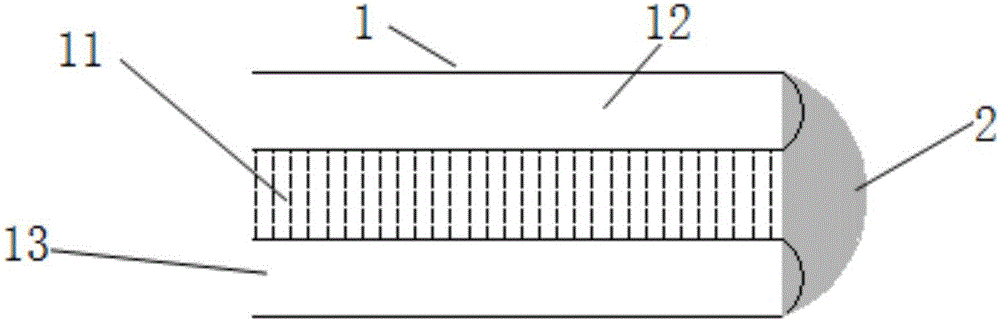

[0034] Such as figure 1 As shown, a new double-glass solar module includes a double-glass solar module body 1 and wrapping 2, and the wrapping 2 is located around the double-glass solar module body 1.

[0035] The double-glass solar module body 1 includes a filling material 11, an upper glass 12 and a lower glass 13, the filling material 11 is located between the upper glass 12 and the lower glass 13, and the filling material 11 is EVA, POE or PVB.

[0036] The filling material 11 can also be pasted around the component body 1 using small strips made of EVA, POE and PVB.

[0037] After lamination, the double-glass solar module body 1 uses auxiliary tooling with air holes for edge sealing. The auxiliary tooling is made of high-temperature and high-pressure-resistant materials, and will not pollute the double-glass solar module during lamination. After the laminated double-glass solar module body 1 is cooled, the auxiliary tooling is torn off, and the overflowing filling materi...

Embodiment 2

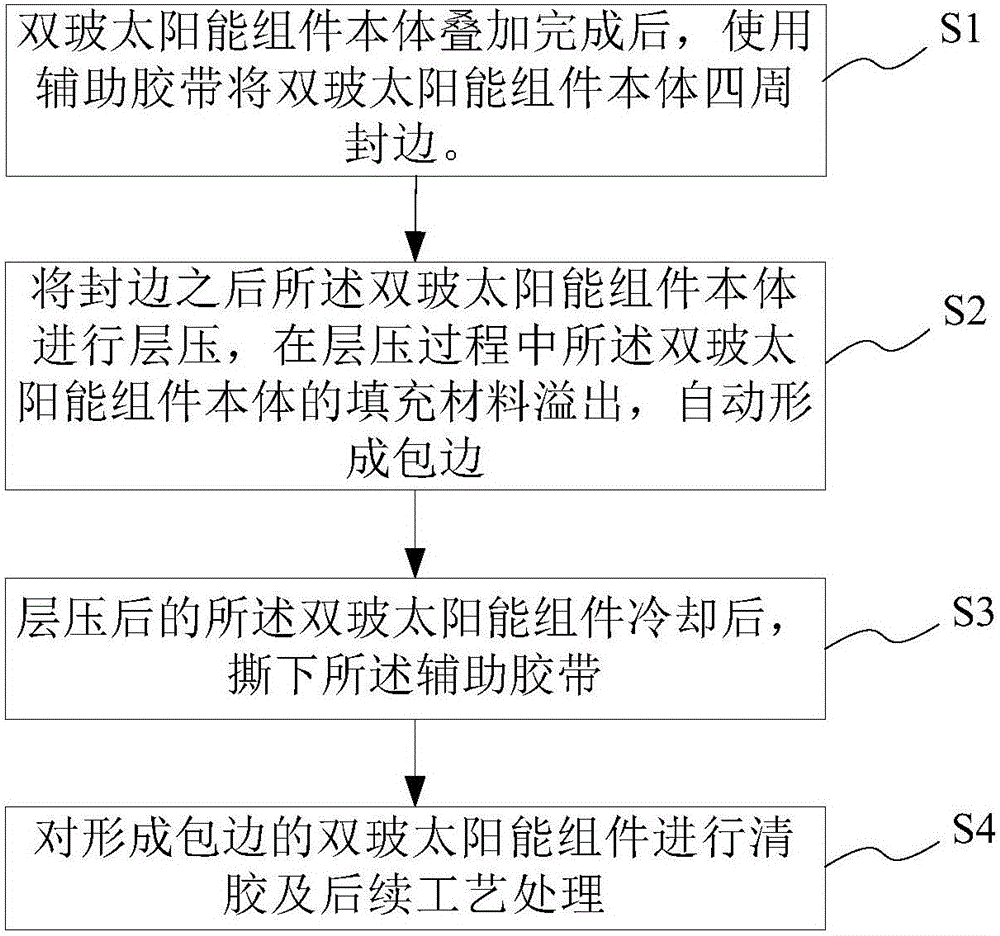

[0043] A new double-glass solar module edge sealing method is improved on the basis of the conventional double-glass solar module production process. The process is as follows figure 2 shown, including the following steps:

[0044] In step S1, after the stacking of the double-glass solar module body is completed, use auxiliary adhesive tape to seal the sides of the double-glass solar module body.

[0045] The auxiliary tape has a hole in the center, good air permeability, high temperature and high pressure resistance, and covers all four sides of the double-glass solar body when sealing the edge. Only one tape is used for each side. The tape that is broken in the center cannot be continued, and each side is redundant. The tape needs to be cut off.

[0046] In step S2, the body of the double-glass solar module is laminated after the edge sealing, and the filling material of the body of the double-glass solar module overflows during the lamination process, forming an edge wrap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com