Molded lid and method for fitting said lid onto container, and sealing method

A technology for containers and fitting parts, applied to packaging sealing/fastening, caps, capping, etc., can solve problems such as productivity decline, time spent on schedule, and wall thickness restrictions, and achieve the effect of improving high-speed productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] (formed cover)

[0036] The shaped cap according to the present invention will be explained using the drawings.

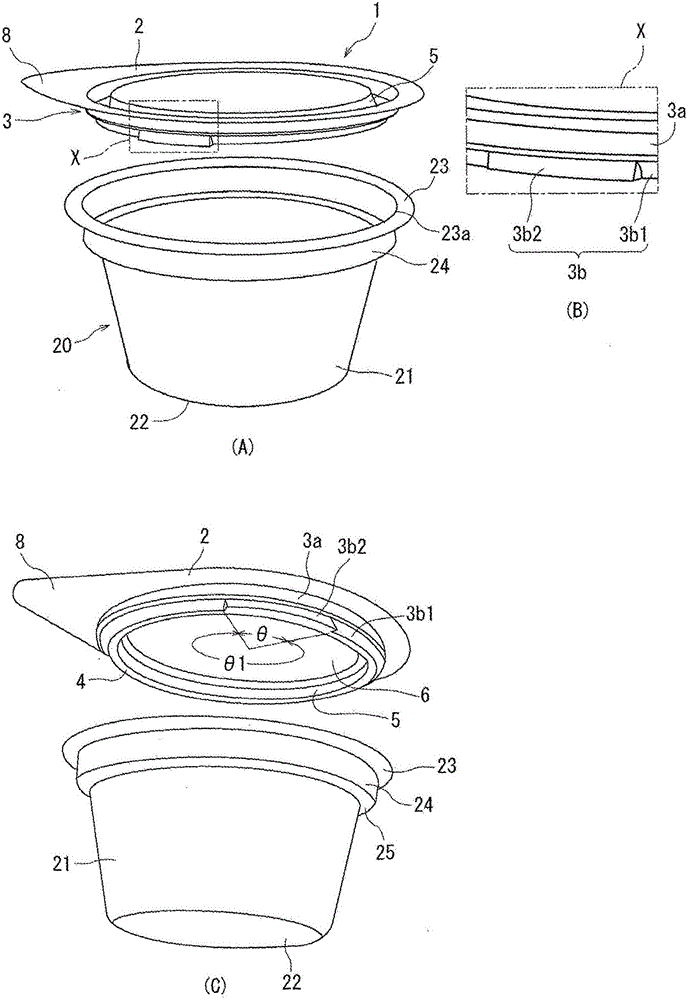

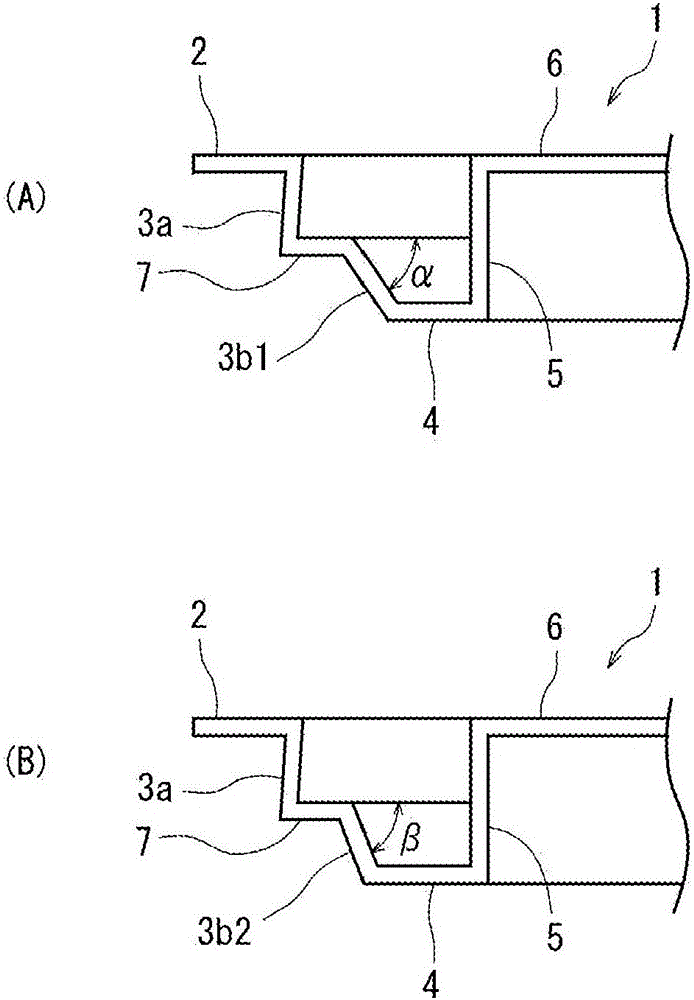

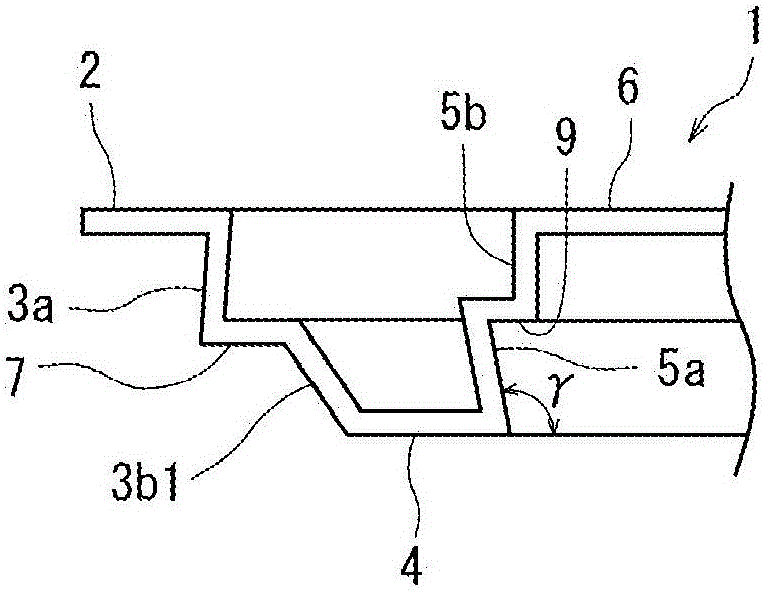

[0037] refer to figure 1 and figure 2 The forming cover 1 of the present invention is roughly composed of a flange portion 2, an outer side wall portion 3 hanging down from the inner peripheral edge of the flange portion 2, an annular portion 4 extending horizontally inward from the lower end of the outer side wall portion 3, and a ring portion 4 extending from the ring. The inner side wall portion 5 extending upward from the inner peripheral edge of the shape portion 4 and the top plate 6 located horizontally inward from the upper end of the inner side wall portion 5 . A grip portion 8 wider than other portions of the flange portion 2 is formed in a part of the flange portion 2 . The forming cover 1 can be opened by holding the grip portion 8 and pulling the grip portion 8 upward.

[0038] In the above-mentioned basic structure of the forming cap accor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com