Slide jig for connection of surface materials, and method for laying surface material using slide jig for connection

A laying method and technology of sliding direction, which are applied in the directions of pipeline laying and maintenance, construction material processing, mechanical equipment, etc. reliability issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

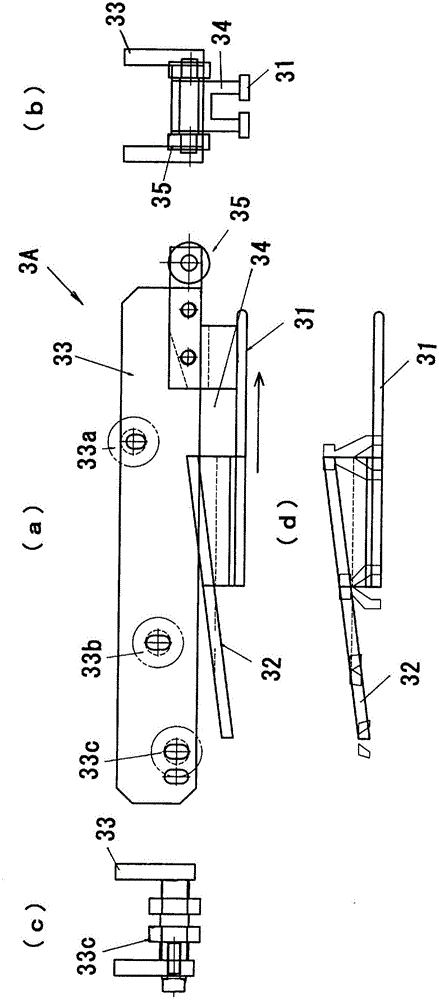

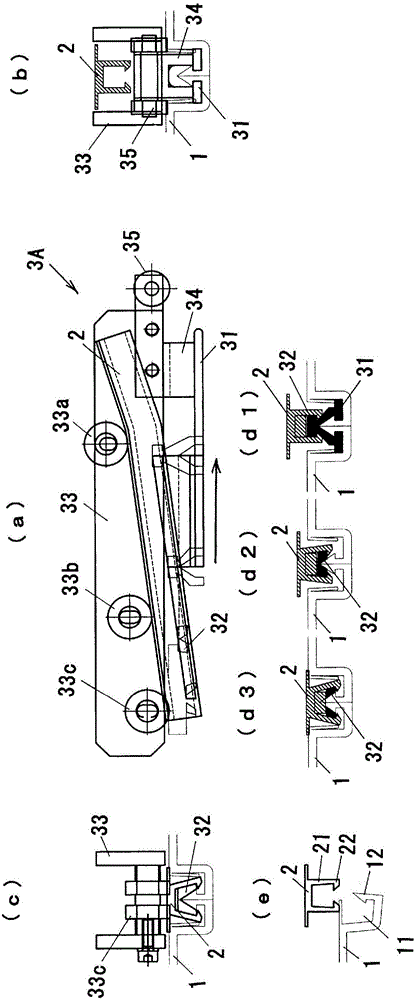

[0057] Figure 1 ~ Figure 2 The first embodiment of the slide tool for connecting face materials according to the present invention is shown. The sliding tool 3A (hereinafter, sometimes referred to as "tool") for connecting the face materials is as follows: Figure 8 As shown in (a) to (c), the surface material fitting claws 12 formed in the grooves 11 formed on the ends of the width direction of each surface material 1 and the surface material formed opposite to the protrusions 21 are used to The connecting member fitting claws 22 are respectively fitted to connect the strip-shaped inner surface members 1 (hereinafter referred to as "face materials 1") arranged side by side in the width direction to each other, and the protrusions 21 are formed in parallel across the sides of the two face materials 1. The inner surface member connection part 2 (hereinafter referred to as "surface material connection part 2") arranged at the end in the width direction is formed in parallel wit...

Embodiment 2

[0078] However, a traction part (not shown) is provided at the front part of the slide tool 3A in the sliding direction for connecting the surface materials, and a steel cable (not shown) is connected to the traction part, and the operator or the operator passes through the front part of the tool 3A. When a work machine such as a winch pulls the tool 3A and slides the tool 3A, for example, when a pulling part is provided in front of the pressing part 33 and the tool 3A is pulled via the pressing part 33, as in Figure 4 As shown in (b), the rear part of the pressing part 33 floats, and the surface of the surface material connecting member 2 cannot be sufficiently pressed by the pressing part 33, and the fitting claw 12 of the surface material connecting part and the fitting claw 22 of the surface material connecting part Potentially unreliable.

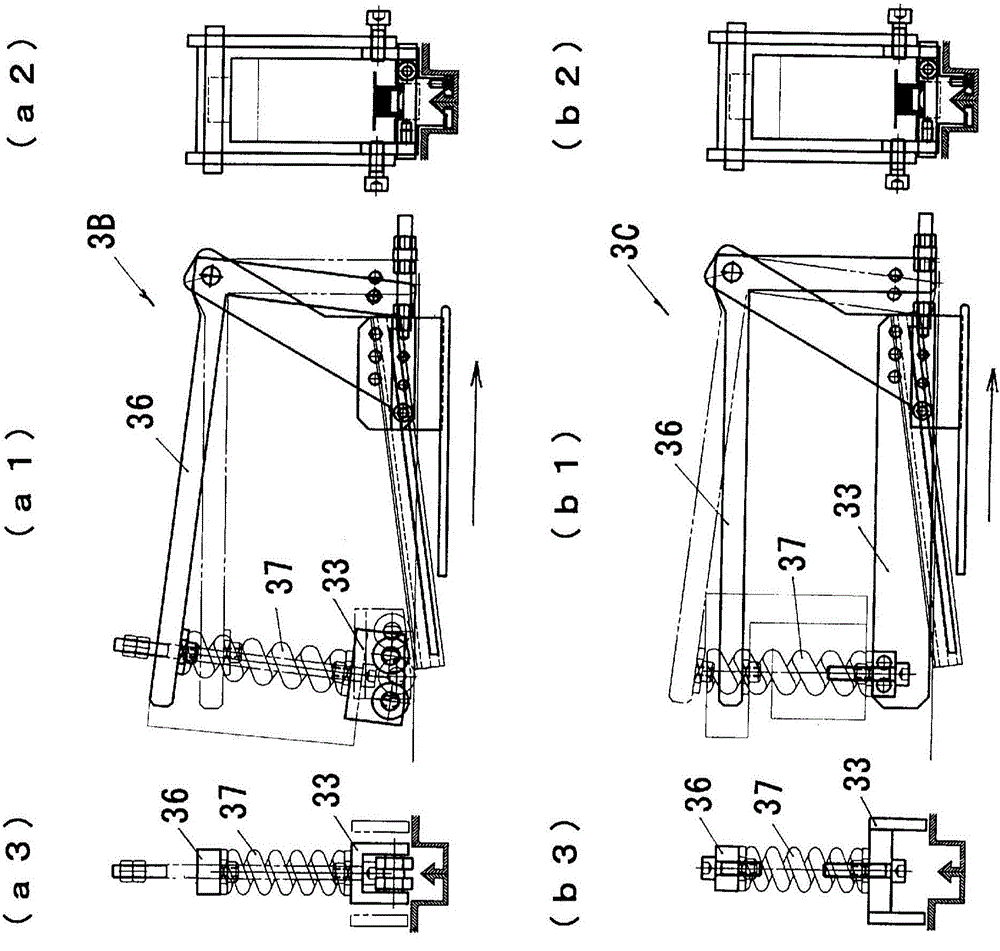

[0079] To prevent this floating phenomenon, such as Figure 3 ~ Figure 4 As shown in the first mode and the second mode of the seco...

Embodiment 3

[0083] Figure 5 A third embodiment of the slide tool for connecting face materials according to the present invention is shown.

[0084] Such as Figure 8 As shown in (a) to (c), the surface material connecting slide tool 3D is used to make the surface material fitting pawl 12 formed in the groove 11 formed on the end portion of the width direction of each surface material 1 and the The surface material connecting member fitting claws 22 formed opposite to the protrusions 21 are respectively fitted to connect the strip-shaped inner surface members 1 (hereinafter referred to as "surface materials 1") arranged side by side in the width direction to each other, and the protrusions 21 The inner surface member connecting member 2 (hereinafter referred to as "face material connecting member 2") arranged across the ends of the width direction of both face materials 1 is formed in parallel, and the supporting part 31 inserted into the groove 11 of the face material 1, The pressing p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com