A milling deformation control device and method for tapered thin-walled parts

A technology for thin-walled parts and deformation control, applied in positioning devices, metal processing equipment, metal processing machinery parts, etc., can solve the problems of large deformation in milling, out-of-tolerance roundness, uneven wall thickness, etc., and achieve convenient clamping and adjustment , The wall thickness is uniform without tolerance, and the bonding effect is reliable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further elaborated below in conjunction with the accompanying drawings of the description.

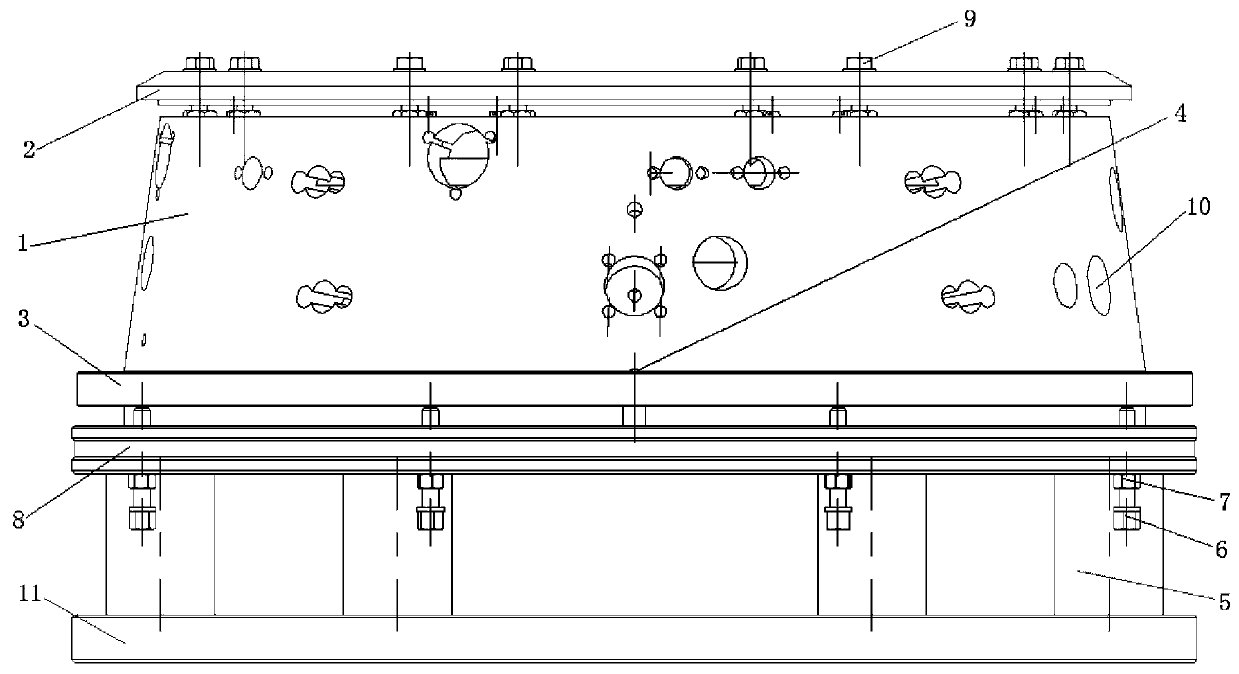

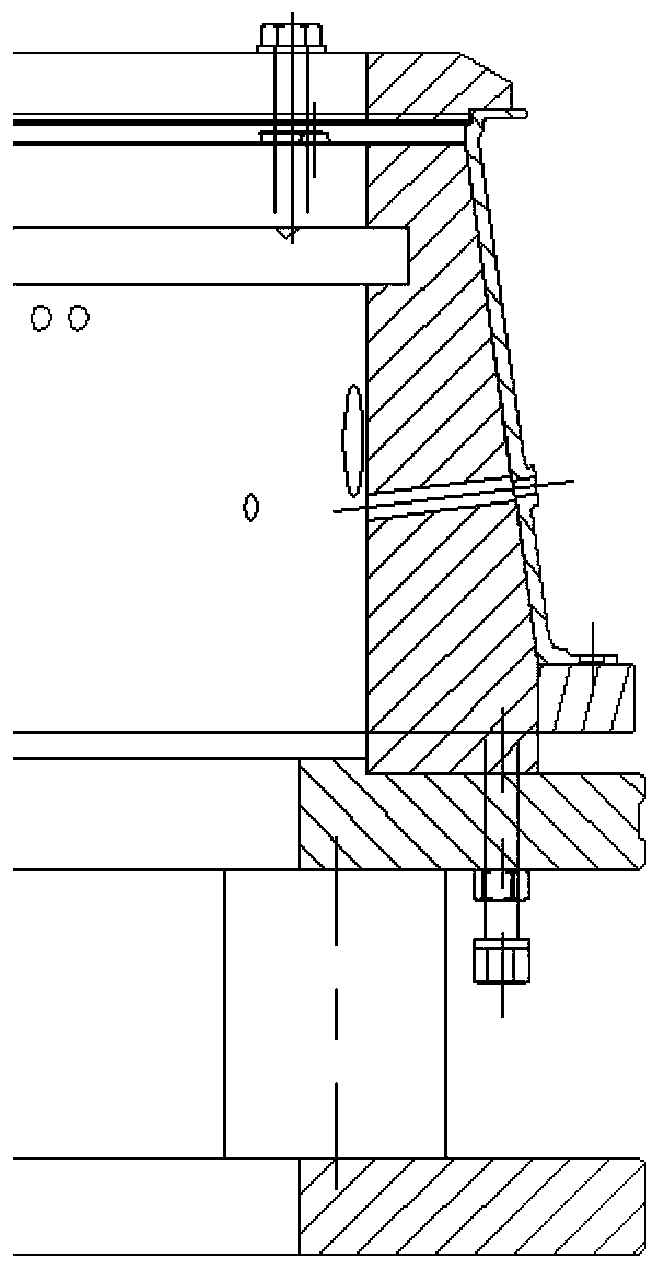

[0034] Such as figure 1 As shown, the present invention is a milling deformation control device for conical thin-walled parts, which is a fixed conical surface tensioning mechanism formed by the fixture body in cooperation with the conical surface 1, the upper gland 2 and the bottom auxiliary support ring 3, wherein the fixture The main body matching cone 1 is placed on a base, the bottom auxiliary support ring 3 is fixed on the outer periphery of the lower part of the fixture main body matching cone 1, and the upper gland 2 is installed on the upper end surface of the fixture main body matching cone 1 to limit the parts to the fixture The main body fits between the conical surface 1 , the upper gland 2 and the bottom auxiliary support ring 3 .

[0035] figure 1 Among them, the fixed cone tensioning mechanism has an adjustable structure, which can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com