Moldboard plow structure assembly

A plow-type plow and assembly technology, applied in plows, agricultural machinery and implements, applications, etc., can solve the problems of poor penetration of the plow tip into the soil, affecting work, and easy wear and tear, so as to reduce operating costs, improve production efficiency, and enhance turning. The effect of the soil effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

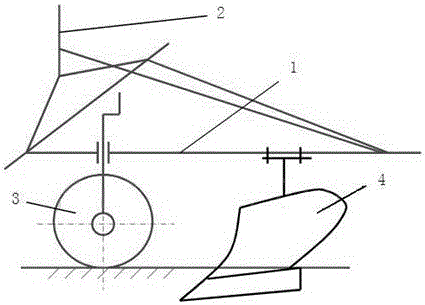

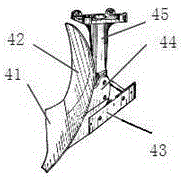

[0016] Such as figure 1 As shown, a conventional plow structure assembly includes a frame 1, and a suspension device 2 is fixedly installed on the upper part of the frame 1; There is a main plow body 4, and the main plow body includes a plow share 41, a plow wall 42, a plow side plate 43, a plow holder 44, and a plow post 45, and the plow share 41 and the plow wall 42 are fixed on the plow holder 44, and the plow share 41 and the plow wall 42 constitute The working curved surface, the plow post 44 and the plow post 45 are fixedly connected, or the plow post and the plow post form an integral body. The plowshare is a plowshare made of manganese steel. The plow hold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com