High efficiency energy-saving sowing device

A high-efficiency, energy-saving, and equipment-based technology, applied in applications, coatings, shovels, etc., can solve problems such as low efficiency, impact on crop growth, and high manpower consumption, and achieve the goal of improving work efficiency, improving soil turning efficiency, and good collection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

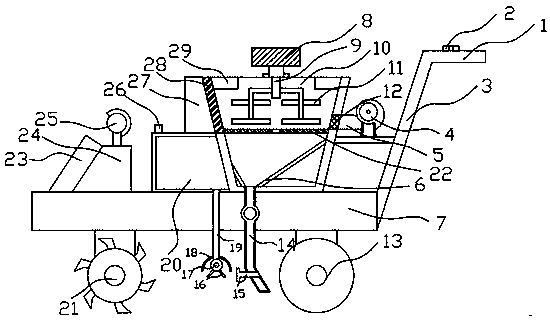

[0020] Such as Figure 1-4 As shown, the high-efficiency and energy-saving seeding equipment includes a base plate 7, a separation box 10 is installed above the base plate 7, a water collection box 20 is provided on the left side of the separation box 10, and a water inlet 26 is provided on the left side of the water collection box 20. A dust collection box 27 is installed on the top, and a filter screen 28 is provided at the junction of the dust collection box 27 and the separation box 10. The bottom plate 7 is provided with a rolling wheel 13 and a turning wheel 21, and the right end of the bottom plate 7 is connected to the push rod 3 , the push rod 3 is connected to the handle 1, and the push switch 2 is installed on the handle 1. The device is small in size and strong in flexibility. It can screen the seeds poured into the separation box and remove dust, which indirectly improves the germination rate of seeds. The dust enters the dust removal box from the filter screen, w...

Embodiment 2

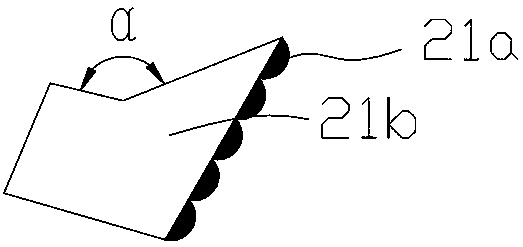

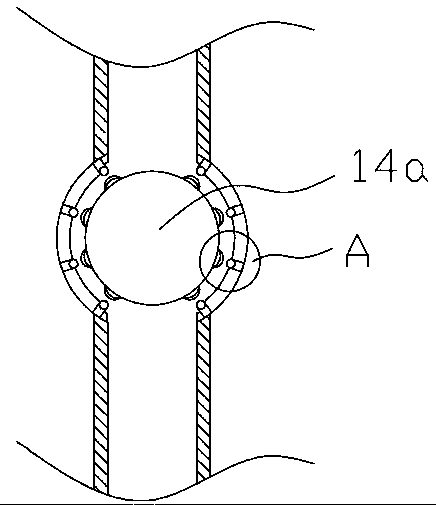

[0030] When the high-efficiency and energy-saving seeding equipment of the present invention is actually used: the device is pulled into the uncultivated land, the seeds are poured into the separation box 10 from the feed port 29, the motor 8 at the upper end of the separation box 10 is started, and the output shaft drives the rotating shaft The stirring shaft 11 on the 9 rotates, and the stirring shaft 11 stirs the seeds poured in for a certain period of time, and then cooperates with the blowing of the blower fan 4 to screen the seeds, and all bad seeds are blown into the dust box 27 together. processing, better seeds will fall through the sieve 22 on the slant plate 6 of the lower floor, and the seeds will enter the seed pipe 14 in turn, press the push switch 2 to make the device start and push forward, and turn over in the process of advancing. The soil wheel 21 turns over the soil, and then controls the battery valve 15 on the seed pipe 14 to sow the seeds. When sowing, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com