Novel cupboard

A cabinet and a new type of technology, applied in the field of furniture products, can solve the problems of easy detachment of welding points, easy rusting of welding points, and few improvements, so as to achieve a product that is not easy to rust or deform, insect-proof, moisture-proof, solid, and not easy to rust Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

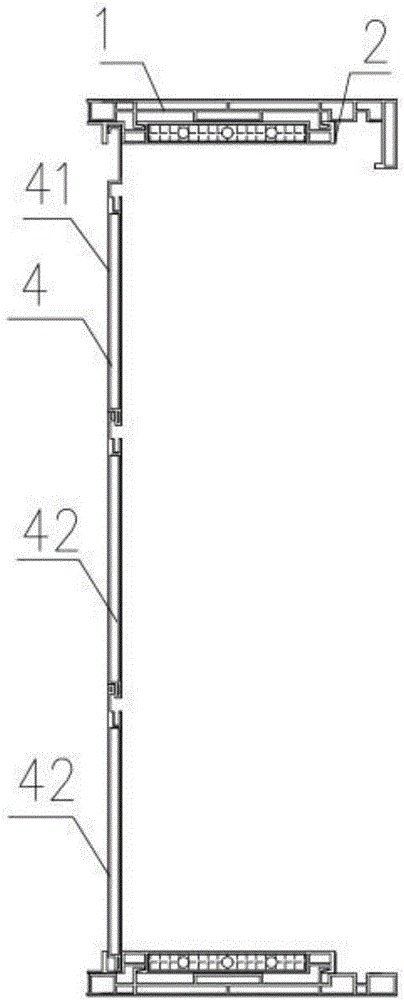

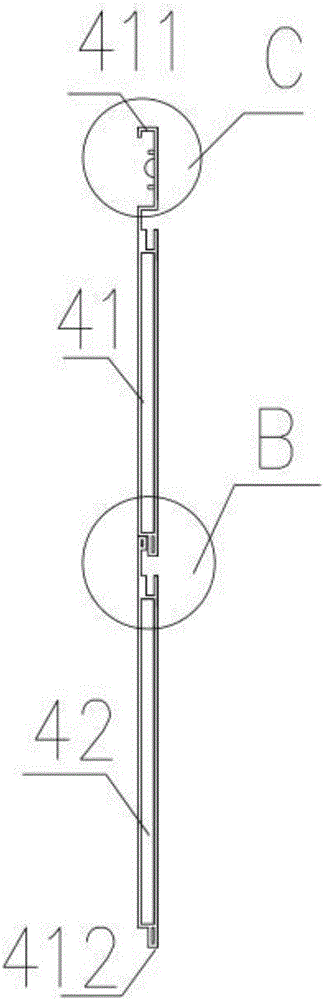

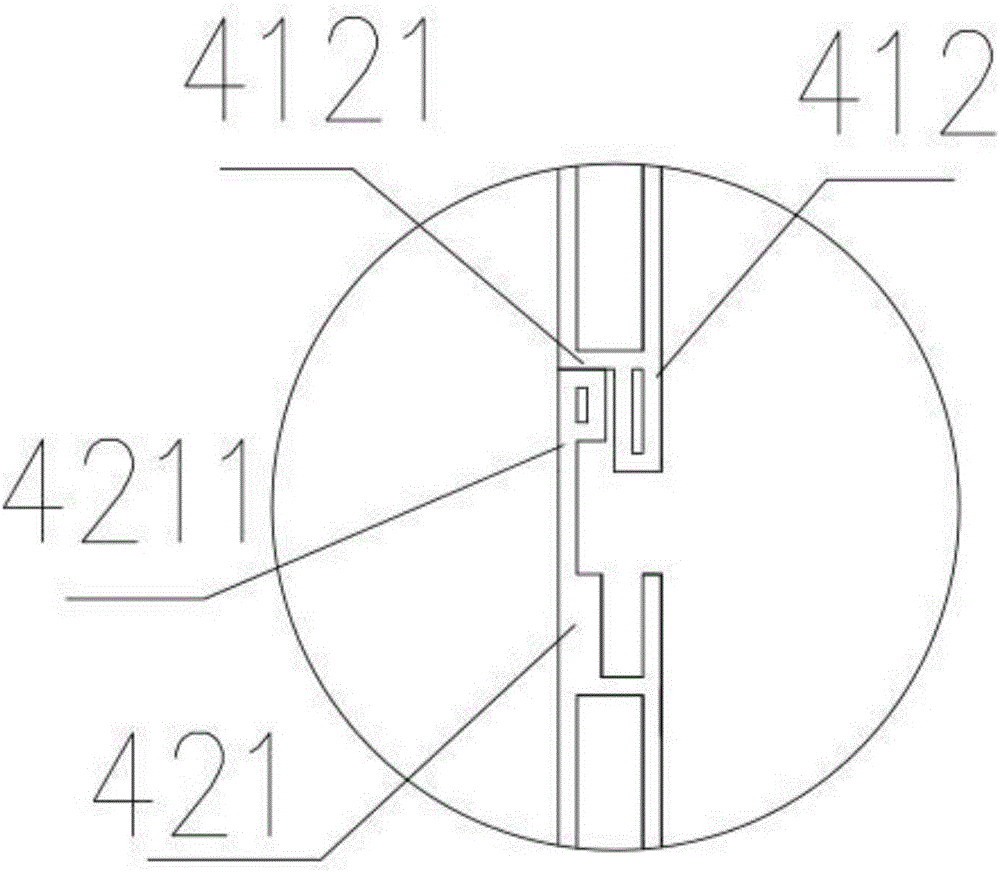

[0044] Example 1, such as Figure 5 with Image 6Shown: a new type of cabinet, including the upper top plate 1, the upper top plate 1 is connected with the table top 2, the upper top plate 1 and the table top 2 are made of integrally formed metal material, and the table top 2 is provided with an accommodation groove 21 for accommodating Inside the groove 21, there is a plate part 3, and the plate part 3 is provided with a mounting hole 31; the table top 2 is located below the upper top board 1, and one side of the table top 2 is provided with a back board connecting groove 23 for connecting the back board of the cabinet, and the upper top board 1 is provided with a buckle 15, and the table panel 2 is provided with a buckle 24 that cooperates with the buckle 15 to complete the connection and fixation. The buckle 15 includes a lower italic body 151 that gradually slopes downward when approaching the buckle 24, and the buckle 24 includes According to the upper inclined body 241 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com