A Trimming Die with Combined Cutting Edge

A combined, cutting-edge technology, used in manufacturing tools, forging/pressing/hammer devices, forging/pressing/hammering machines, etc. Cost, long process time and other issues, to achieve the effect of good applicability and practicability, extended service life and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

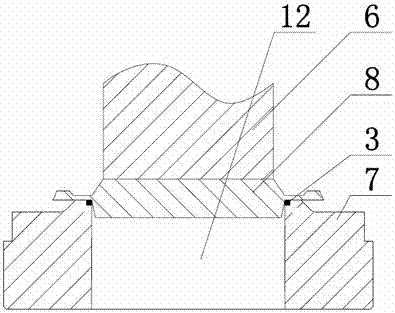

[0033] Cutting die, if attached figure 1 As shown, the edge trimming of the process part 8 is usually trimmed by the trimming punch 6 and the matching trimming die 7, so that it has a stamping die with a certain height, diameter and shape, which is mainly used for trimming the stretched parts. The edge makes the end face flat and beautiful, which is convenient for the next step of assembly.

[0034] Since the cutting edge of the trimming die is in a state of high temperature and stress concentration when working, the material of the cutting edge is often required to have high hardness and wear resistance, so it usually uses a high alloy with high hardness and high wear resistance. However, due to the high hardness of the high alloy, it is relatively difficult to process it, and it is difficult to fix it on the matrix of the die through the bolt or screw through the cutting edge. Therefore, welding is often used in the production of the existing trimming die, especially It is ...

Embodiment 2

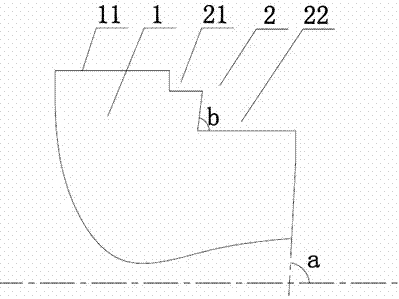

[0049] This embodiment is similar to the overall structure of Embodiment 1, the difference is that: as attached Figure 5 As shown, the first side wall 32 of the cutting edge 3 is located on the same plane as the side wall of the groove 12, but the included angle c between the second side wall 33 of the cutting edge 3 and the horizontal plane is equal to the included angle a, and the included angle b is equal to the included angle a minus 1°-3°, which is set because, since the included angle c is greater than the included angle b, the second edge of the cutting edge 3 A certain angle will be maintained between the side wall 32 and the side wall of the second stage 22, that is, there is a certain gap between them, and because the whole device is at a higher temperature during edge trimming, the cutting edge 3 will have a certain thermal expansion, so that it will present an interference fit state with the matrix of the die, which is beneficial to increase the firmness of the cu...

Embodiment 3

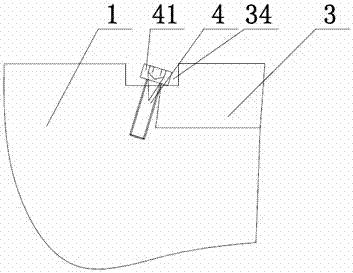

[0053] The overall structure of this embodiment is similar to embodiment 1 or 2, the difference is: Figure 6 As shown, the pressing device includes a gasket 5, and the gasket 5 is pressed on the bottom surface of the first stage 21 by a screw 4 vertically arranged on the bottom surface of the first stage 21, The gasket 5 extends to the bottom surface of the notch, and fixes the cutting edge 3 in the cutting edge installation groove 2; of course, the screw 4 may not be perpendicular to the bottom surface of the first stage 21 , as long as the gasket 5 can be fixed on the bottom surface of the first stage 21 .

[0054] Here, the cutting edge 3 is pressed down by adding a washer, so the requirements for the position and setting angle of the screw 4 are further reduced, as long as the screw 4 can hold the washer 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com