Skylight glass water guide structure and water guide lugs

A technology of water-conducting structure and window glass, which is applied in the direction of roof, transportation and packaging, vehicle parts, etc., can solve the problems of limiting the diversity of glass size and unable to adjust glass size at will.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

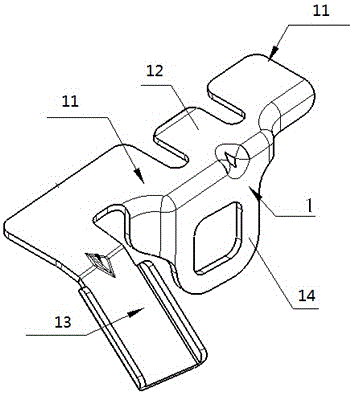

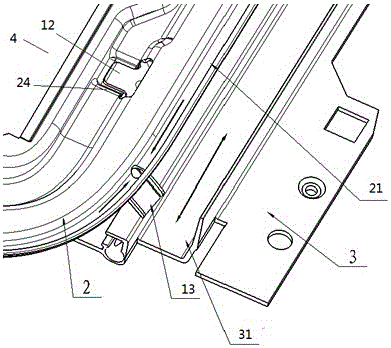

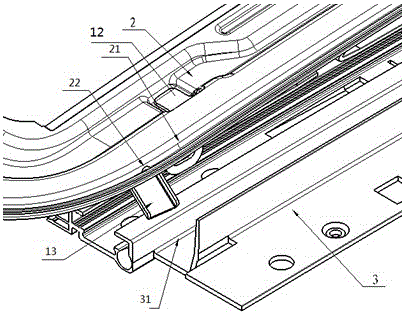

[0023] Such as Figure 1 to Figure 5 As shown, the water guiding lug 1 disclosed in the present invention is provided with a downfall groove 13 at one end, and an assembly surface is provided at the other end. The assembly surface is welded and assembled at the bottom of the sunroof guide rail; the precipitation inlet of the precipitation tank 13 is used to be arranged under the water storage tank 21 facing the skylight glass support plate 2 and facing the water accumulation hole 22, and the precipitation outlet of the precipitation tank 13 is used to extend to the support plate Above the drainage groove 31 of the sunroof guide rail 3 of the sunroof glass support plate 2

[0024] The water guide lug 1 is a metal integral structure, which is realized by technology, and solves the problem that the water accumulation hole 22 of the skylight glass support plate 2 cannot directly discharge water into the drainage groove 31 of the skylight guide rail 3 .

[0025] Such as Figure 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com