Chemical tank transporting device

A transportation device and chemical tank technology, applied in the field of chemical tank transportation devices, can solve the problems of wasting manpower and material resources, delaying time, reducing production efficiency, etc., and achieving the effects of energy saving, convenient transportation, and reasonable structural design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

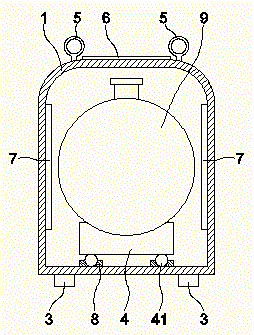

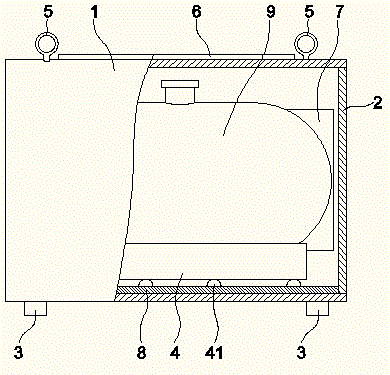

[0015] Such as figure 1 and figure 2 As shown, a chemical tank transportation device of the present invention includes a box body 1, one side of the box body 1 is provided with a box door 2 that can be opened or closed, and the bottom of the box body 1 is provided with a support 3 The inside of the box 1 is provided with a trolley 4 for transporting chemical tanks 9; the top of the box 1 is provided with a lifting ring 5 and a photovoltaic power supply system 6, and an electric The heating plate 7 is electrically connected to the photovoltaic power supply system 6 .

[0016] The photovoltaic power supply system 6 includes a solar cell, a controller, an energy storage battery, and an inverter; the controller is electrically connected to the solar cell and the energy storage battery, and the energy storage battery is electrically connected to the inverter. The inverter is electrically connected to the electric heating plate.

[0017] The bottom of the trolley 4 is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com