Traction power system for elevator

A power system and traction technology, applied in the field of elevators, can solve the problems of short service life of parts, high frequency of maintenance, high frequency of replacement of wearing parts, etc., and achieve the effect of improving stability and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

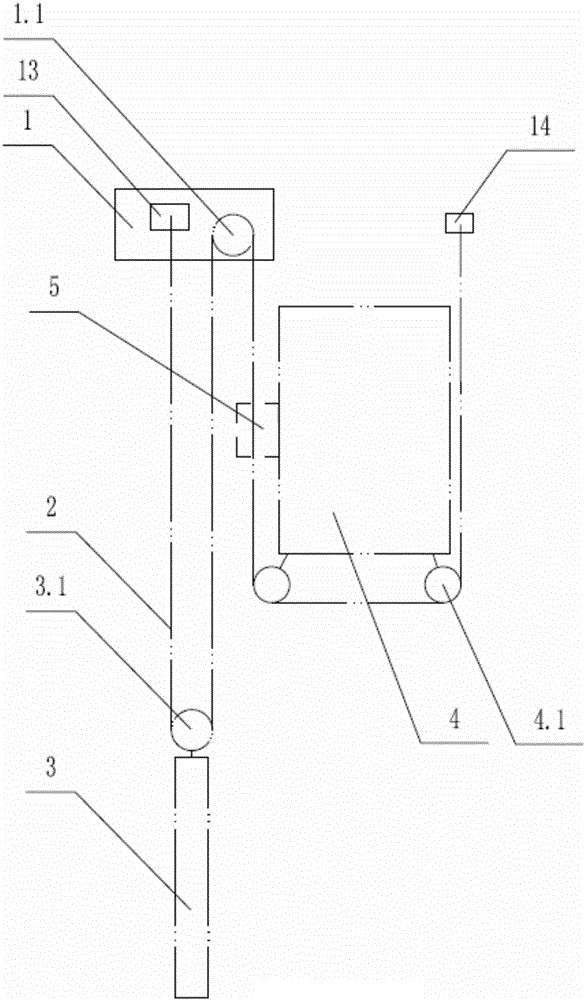

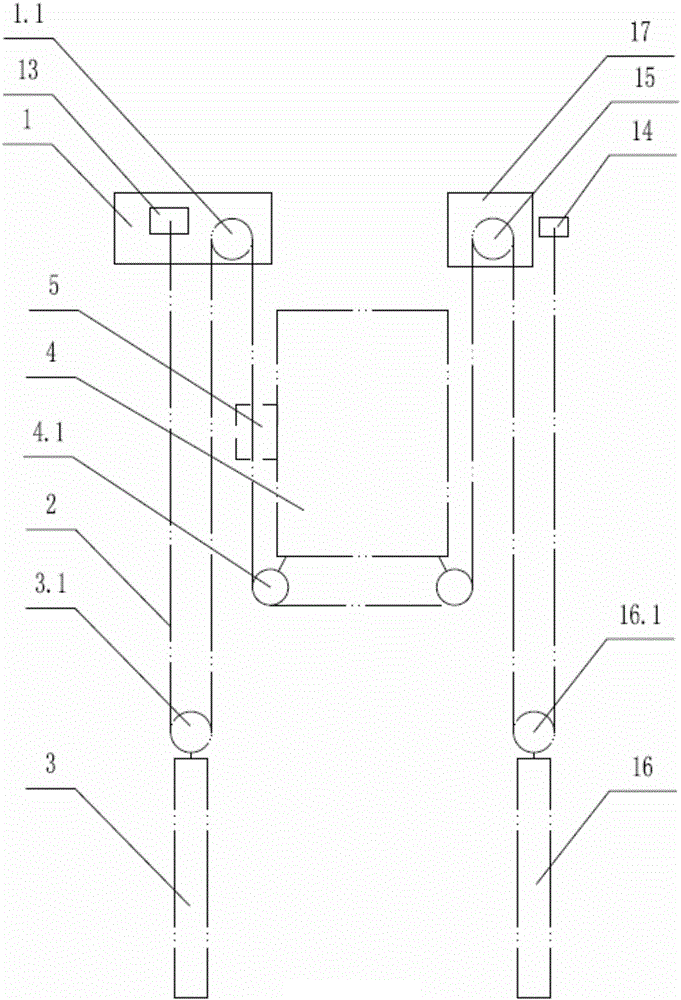

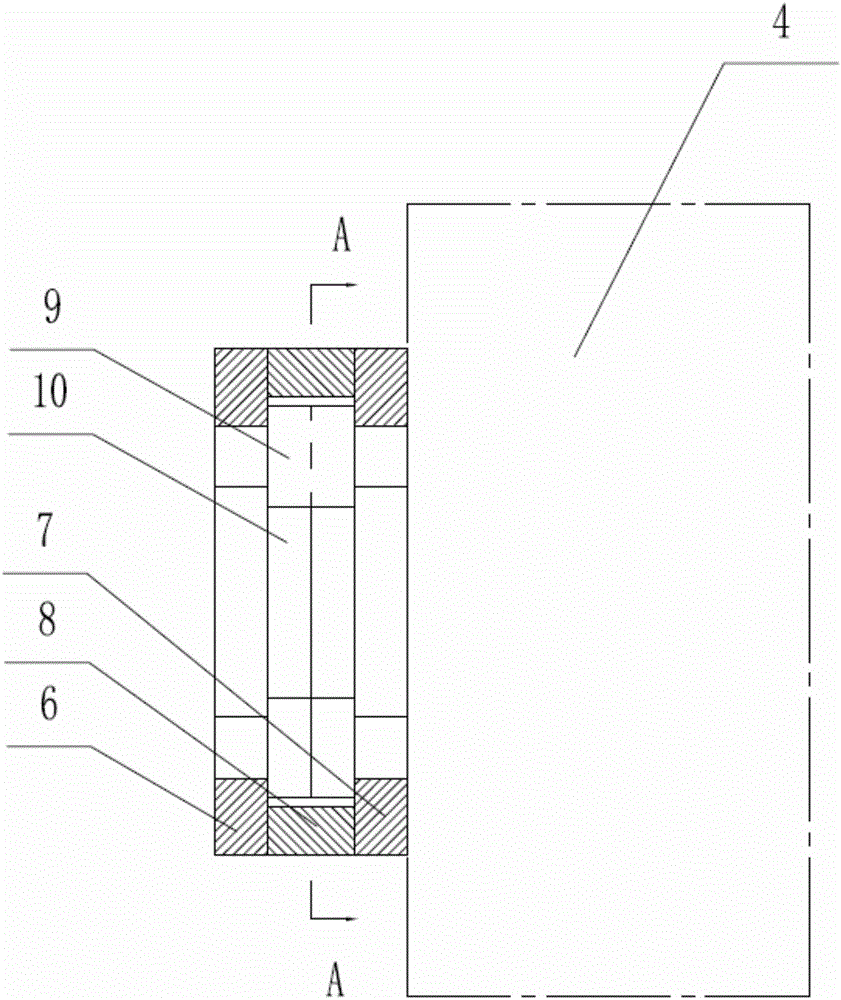

[0023] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

[0024] The invention provides a traction power system for an elevator, which includes a traction machine 1 installed in the elevator shaft, a traction wire rope 2 and a counterweight 3 arranged under the traction machine 1, and is characterized in that: One end of the wire rope 2 is fixed to the casing of the traction machine 1, the other end of the traction wire rope 2 is fixed to the inner wall of the elevator shaft, and the middle part of the traction wire rope 2 encircles the counterweight wheel 3.1, traction The driving wheel 1.1 on the machine 1 and the guide wheel 4.1 arranged at the bottom of the car 4, a pre-tensioning mechanism 5 is provided on the outer wall of the car 4, which is used to draw the wire rope when the counterweight 3 and the car 4 are not aligned. 2 Make the traction wire rope 2 tight when applying force. There are mult...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com