A composition for glass, low surface tension alkali-free glass and its preparation method and application

A low surface tension, alkali-free glass technology, applied in instruments, optics, electrical solid devices, etc., can solve the problems of low thermal stability and formation stability of alkali-free glass plates, and achieve high specific modulus and high strain point. , the effect of high liquidus temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-17

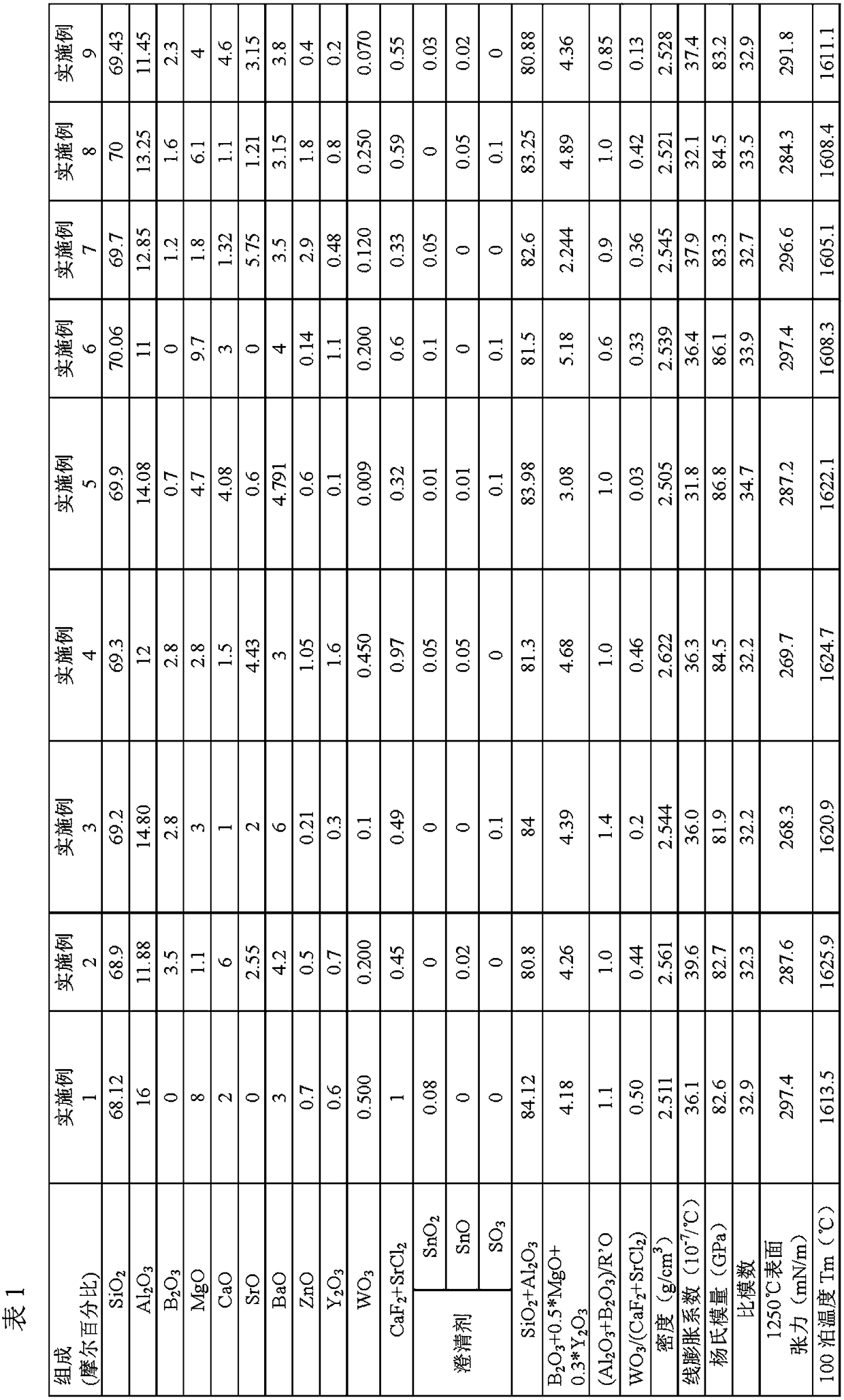

[0076] Weigh the components as shown in Tables 1 and 2, mix well, pour the mixture into a platinum crucible, and then heat it in a resistance furnace at 1530°C for 4 hours, and stir with a platinum rod to expel bubbles. Pour the molten glass into a stainless steel cast iron grinding tool to shape it into a prescribed block glass product. Then, the glass product is annealed in an annealing furnace at 830°C for 2 hours. The power is turned off and the furnace is cooled to 25°C. The glass products are cut, ground, polished, cleaned with deionized water and dried to obtain glass products. The various properties of each glass product were measured, and the results are shown in Tables 1 and 2.

Embodiment 18-20 and comparative example 1-4

[0078] According to the method of Example 3, the difference is that the composition of the mixture and the performance measurement results of the obtained product are shown in Table 3.

[0079] Comparing the data in Table 1-2 and Table 3, it can be seen that the glass prepared by the present invention has lower surface tension and higher overall stability. The glass composition or low surface tension alkali-free glass of the present invention can be used to prepare display devices and / or solar cells, and is especially useful for preparing substrate glass substrate materials for flat panel display products.

[0080] Comparing Example 1 and Example 18, it can be seen that B 2 O 3 +0.5*MgO+0.3*Y 2 O 3 <8mol%, which can significantly improve the overall performance of the prepared glass such as thermal stability and glass formation stability.

[0081] Comparing Example 1 and Example 19, it can be seen that when the glass composition contains B 2 O 3 , Based on the total moles of each com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strain point | aaaaa | aaaaa |

| strain point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap