Method for preventing or retarding salt deposition of delayed coking fractionator

A technology of coking fractionation tower and delayed coking, which is applied in the field of preventing or slowing down salt accumulation in delayed coking fractionation tower, and can solve problems such as inability to completely eradicate salt formation, complex methods, and salt formation in fractionation towers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

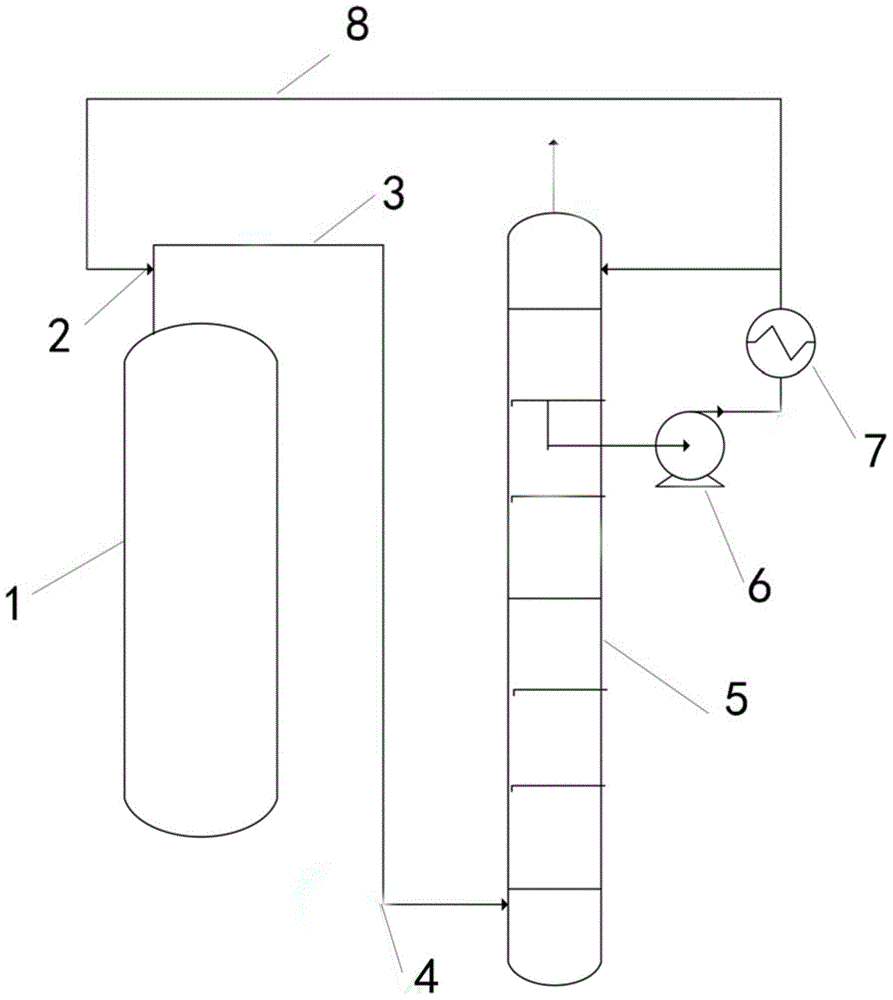

[0037] Example 1, the processing capacity of a delayed coking unit is 2.1 million tons per year, the circulation ratio is 0.2:1, the operating pressure of the delayed coking coke tower is 0.18MPa, and the temperature of coking oil gas generated by the reaction in the delayed coking coke tower is 450-460°C , the coking oil and gas flow into the large oil and gas pipeline at the top of the coke tower through the top of the delayed coke tower, and the circulating oil at the top of the coking and fractionating tower is injected into the large oil and gas pipeline 3 at the top of the coking and fractionating tower through the first injection port, and the injection speed of the circulating oil at the top of the coking and fractionating tower is 28- 30 tons per hour, the temperature of the coking oil and gas in the large oil and gas pipeline 3 at the top of the coking tower is lowered to 415-425 ° C. The effect is that no salt formation is found in the delayed coking and fractionating...

Embodiment 2

[0040] Example 2, the processing capacity of a delayed coking unit is 1.6 million tons per year, the outlet temperature of the coking furnace is 500°C, the operating pressure of the coke tower is 0.16MPa, the circulation ratio is 0.3:1, and the temperature of the coking oil gas generated by the reaction in the coke tower is The temperature is 445-455°C. The coking oil and gas flow into the large oil and gas pipeline at the top of the coke tower through the top of the coke tower. The temperature of the coking oil and gas in the top oil and gas pipeline is cooled. After cooling, the temperature of the oil and gas in the top oil and gas pipeline of the coke tower is reduced to 420-425°C. %, the effect is that no salt formation has been found in the delayed coking fractionation tower for 14 months.

Embodiment 3

[0043] Example 3 A delayed coking treatment capacity is 1.2 million tons per year, the operating pressure of the coke tower is 0.15MPa, the circulation ratio is 0.15:1, the temperature of the coking oil gas generated by the reaction in the coke tower is 440-450°C, and the coking oil gas is passed through the coke The top of the tower flows into the large oil and gas pipeline at the top of the coke tower, and the middle circulating oil is injected into the large oil and gas pipeline at the top of the coke tower through the first injection port. , after cooling down, the temperature of the coking oil gas is 415-420°C. Before the cooled coking oil gas enters the delayed coking fractionation tower, the top circulating oil of the coking fractionation tower is injected into the large oil and gas pipeline at the top of the coke tower through the second injection port, and the coking top circulating oil The injection rate is 8 tons / hour, and its effect is that the coking fractionation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com