A Method for Reducing Negative Bending Moment of T-Frame Bridge

A negative bending moment, cantilever end technology, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of empty, uneconomical, and unsatisfactory bridge alignment requirements for side pier supports, and achieves the prevention of emptying and Drop, improve driving comfort, solve the effect of sagging deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

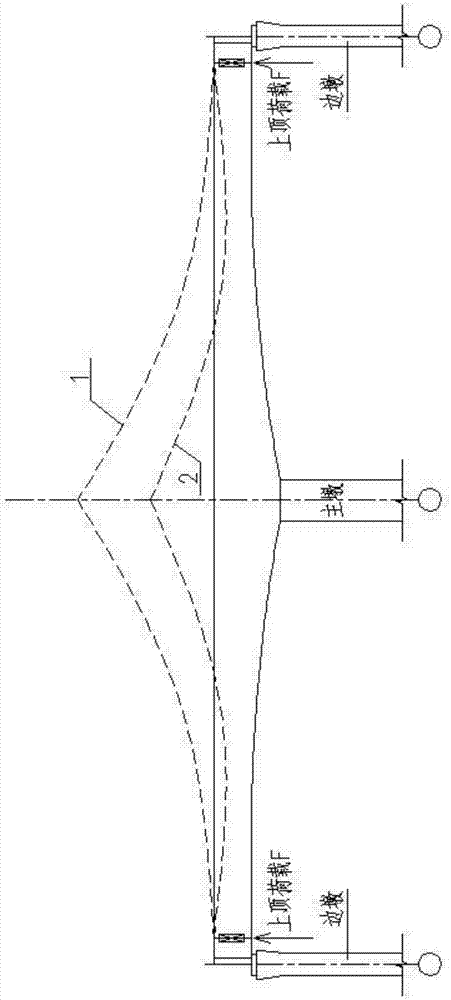

[0012] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0013] The concept of the present invention is: after the construction of the cantilever end of the main girder of the T-structure bridge is completed or the construction of the swivel body is in place, the top load is applied to the cantilever end of the main girder to make it reach the predetermined design elevation and make it meet the requirements of the bridge alignment. In this way, the excessive negative bending moment generated by the main beam at the main pier is eliminated and the reaction force of the side pier support is appropriately increased.

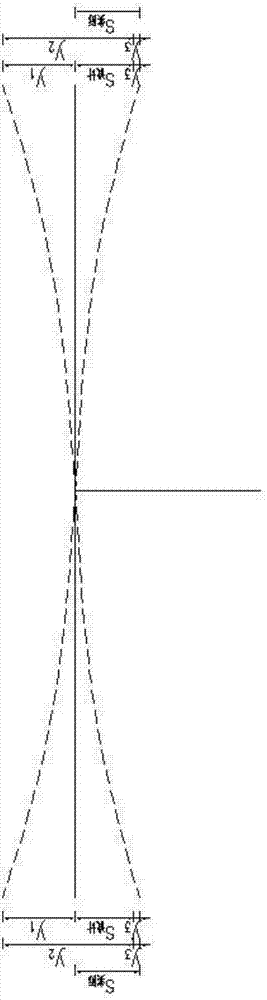

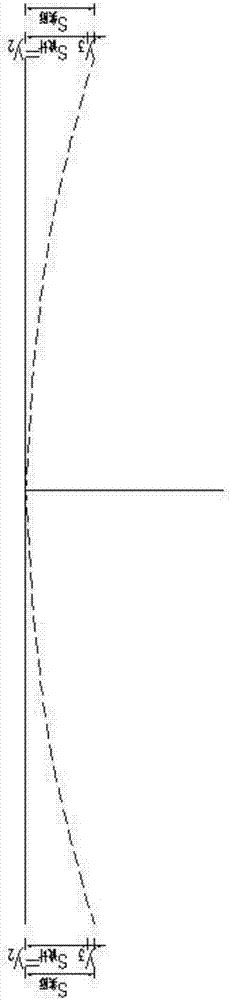

[0014] Concrete scheme of the present invention please refer to Figure 1 ~ Figure 3 , a method for reducing the negative bending moment of a T-structure bridge. In the design stage, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com