Variable Compression Ratio Mechanism for Ring Gear Adjustable Internal Combustion Engine

An internal combustion engine, regulating technology, applied in the direction of machine/engine, electromechanical device, mechanical control, etc., can solve problems such as affecting vehicle sales, reducing vehicle adaptability, etc., to achieve compact structure, rational use of installation space, and small installation space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention is described in detail below in conjunction with accompanying drawing:

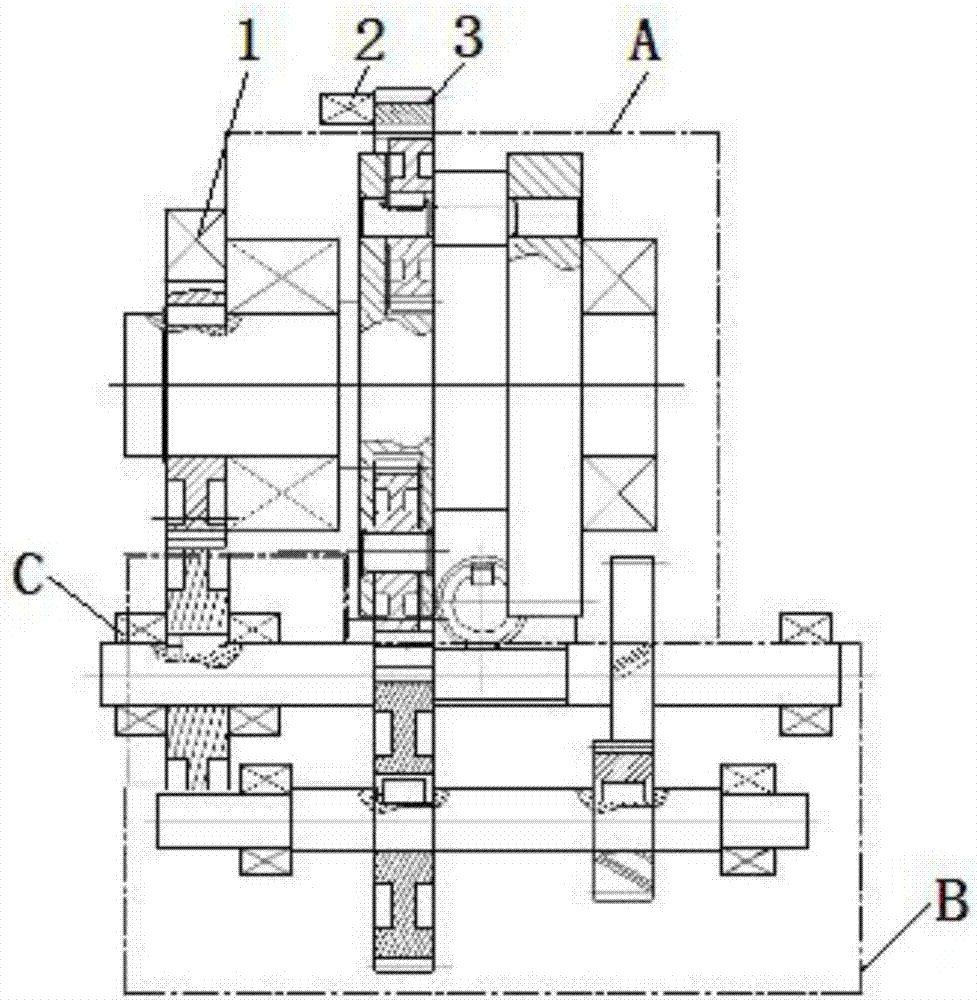

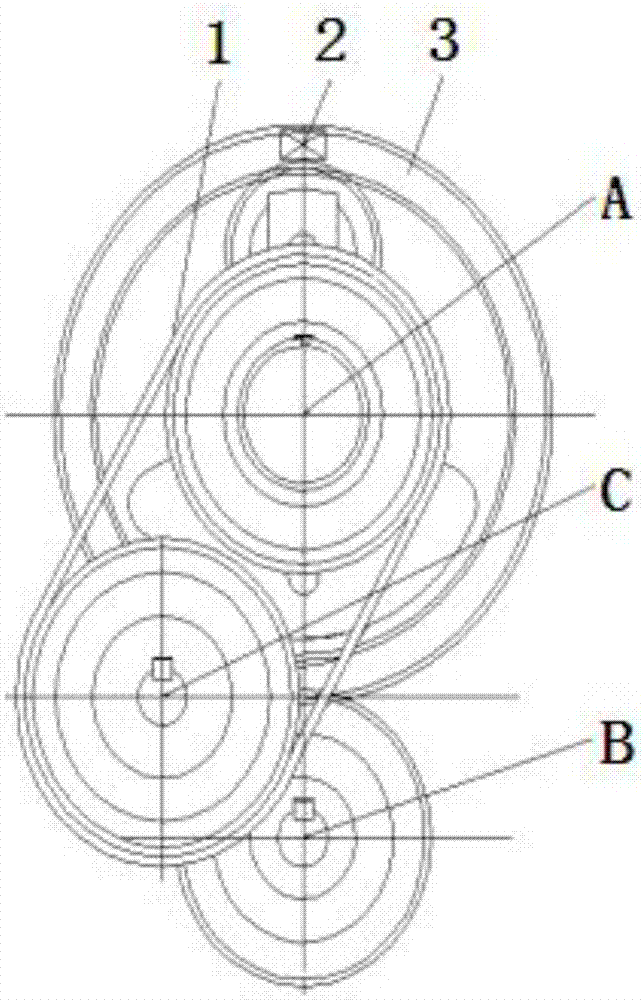

[0051] Such as figure 1 and figure 2 Shown: The internal teeth of belt 1 are respectively driven by belt gear I10 and belt gear II40, the number of teeth of belt gear I10 and belt gear II40 is the same, the speed of belt gear I10 and belt gear II40 are the same, the direction of rotation is the same, crankshaft group A and phase adjustment group C Same revs, same steering.

[0052] The inner teeth of ring gear 3 mesh with gear I6 and gear II8 respectively, and the outer teeth of ring gear 3 mesh with gear III32. The phase rotation angle of ring gear 3 is adjusted through gear III32, thereby changing the phase rotation angle of gear I6.

[0053] The positioning table 2 is processed on the engine body, and together with the connecting rod, it plays an axial positioning role for the ring gear 3 .

[0054] Such as Figure 3 to Figure 12 Shown:

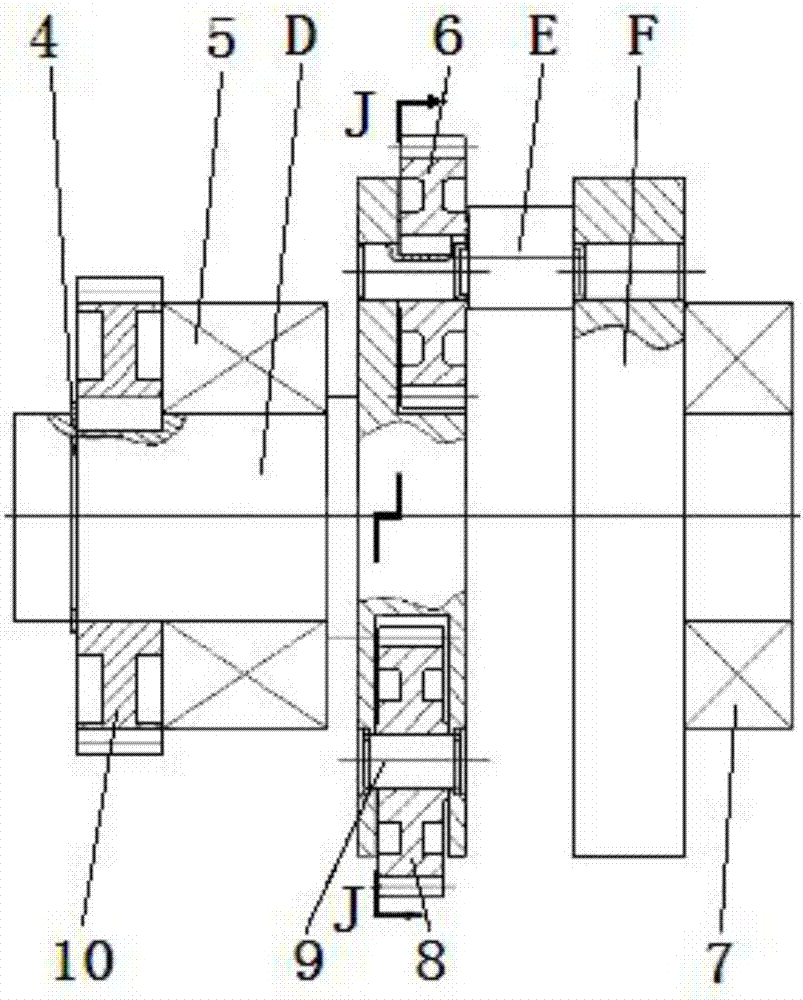

[0055] The snap ring I4 is fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com