Continuous adjustable piston height type self-locking energy-saving engine

A piston height and engine technology, applied in engine components, engine control, machine/engine, etc., can solve the problems of unsuitable engine mass transformation, complex structure, complex mechanism, etc., and achieve simple and reliable adjustment method and continuously variable height , a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

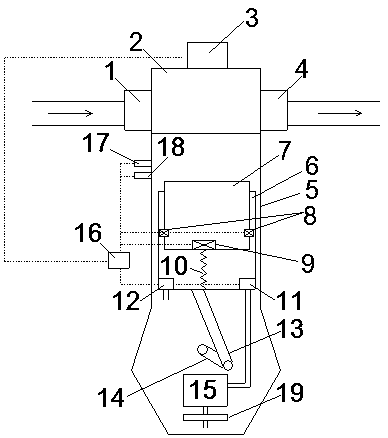

[0019] Embodiment: an energy-saving engine with continuously variable and self-locking piston height, including an engine system and a piston adjustment system, the engine system consists of a cylinder head 2, an electronically controlled fuel injector 3, a cylinder block 5, a main piston 6, a connecting rod 13, Composed of a crank 14 and an oil pump 15, the upper end of the cylinder block 5 is connected to the cylinder head 2, the upper end of the cylinder head 2 is provided with an electronically controlled fuel injector 3, the interior of the cylinder block 5 is provided with a main piston 6, and one end of the main piston 6 and the connecting rod 13 The other end of the connecting rod 13 is connected with the crank 14, which converts the linear reciprocating motion of the main piston 6 into the rotary motion of the crank 14. The lower end of the main piston 6 is provided with an oil inlet 11 and an oil outlet 12 on both sides. The port 11 is connected to the oil pump 15 thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com