Multi-speed transmission for vehicles

A technology for transmissions and vehicles, applied in the direction of vehicle transmissions, vehicle parts, components with teeth, etc., can solve problems such as undesired effects, increase in the number of internal parts of transmissions, reduction in transmission mountability and transmission efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The following description is merely exemplary in nature and is not intended to limit the present disclosure, application or use. It should be understood that throughout the drawings, corresponding reference numerals indicate like corresponding parts and features.

[0016] The present disclosure relates to a multi-speed transmission for a vehicle.

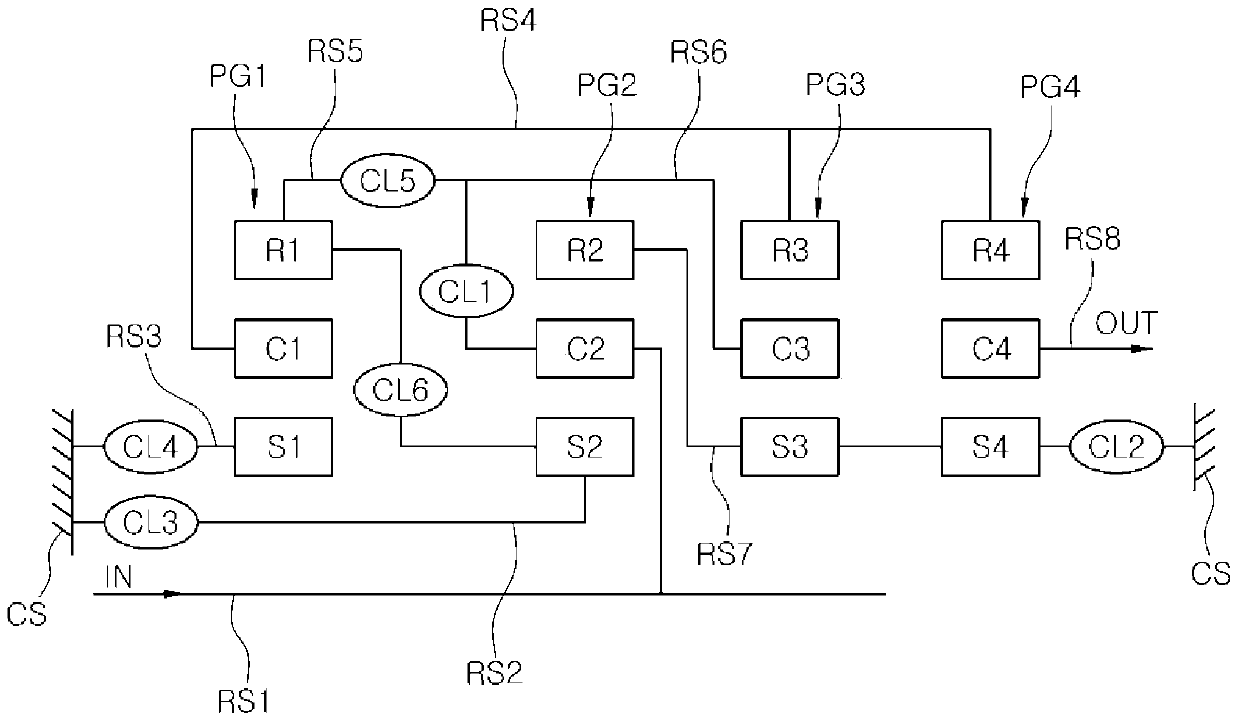

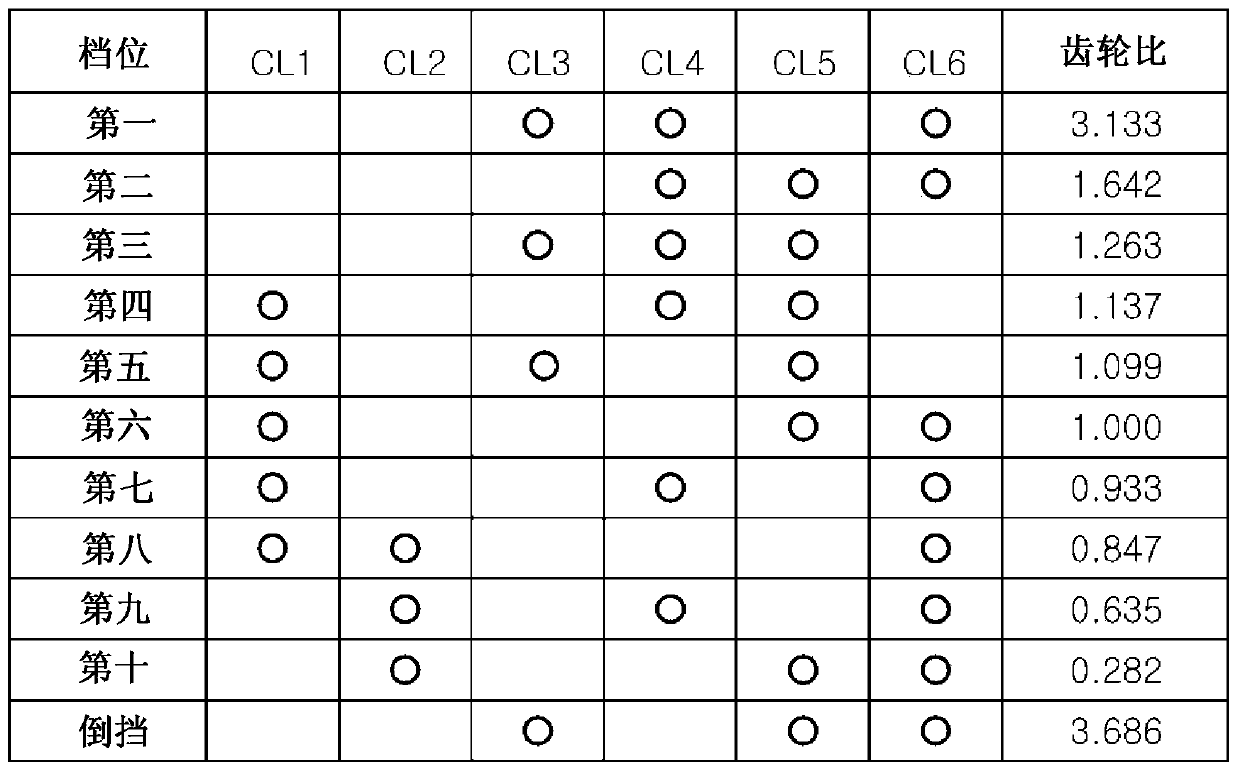

[0017] refer to figure 1 with figure 2 , a multi-stage transmission for a vehicle according to one form of the present disclosure may include: an input shaft "IN"; an output shaft "OUT"; disposed between the input shaft "IN" and the output shaft "OUT" to transmit rotational force The first planetary gear device "PG1", the second planetary gear device "G2", the third planetary gear device "PG3" and the fourth planetary gear device "PG4", the planetary gear devices "PG1", "PG2", "PG3 ” and “PG4” each have three rotating elements; and at least six shift elements (for example, clutches CL1-CL6), connected to the rotating elem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com