Manual split type multi-level water mixing softening valve

A split-type, softening valve technology, applied in the direction of multi-way valves, valve details, valve devices, etc., to achieve the effect of low cost, small overall size, and convenient installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further explained below in conjunction with the accompanying drawings.

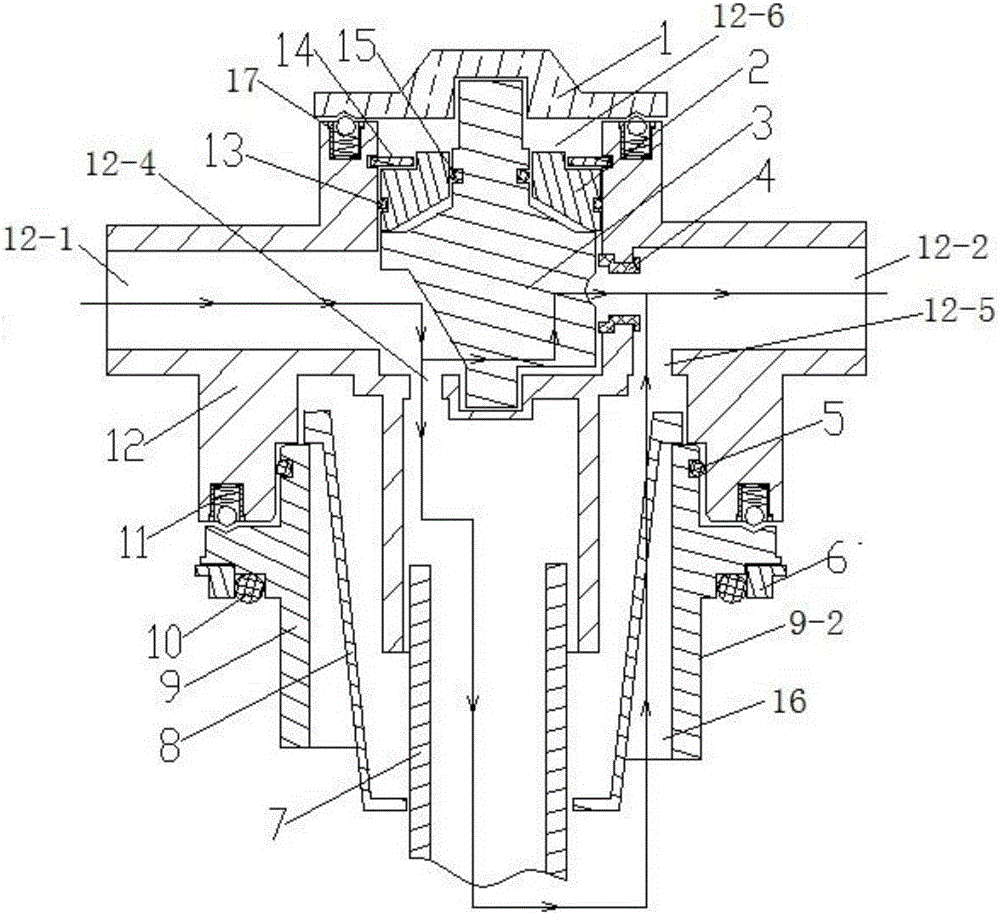

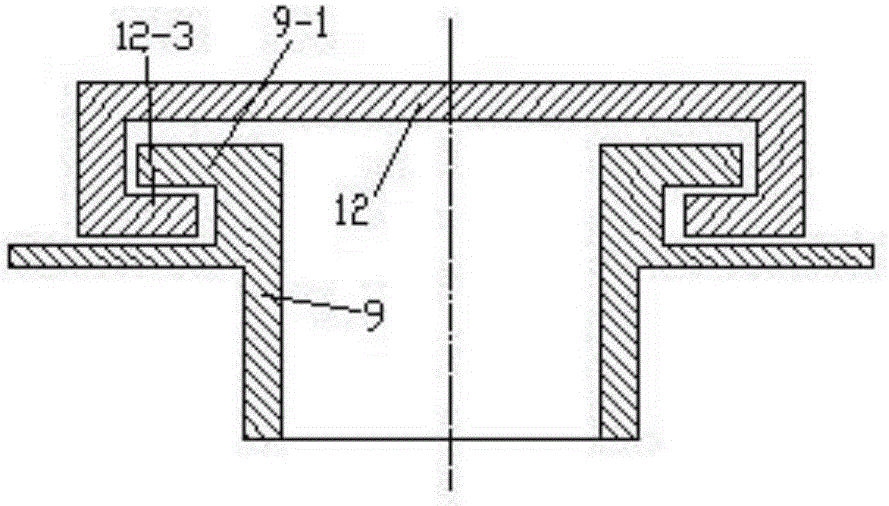

[0026] Such as figure 1 with 2 As shown, a manual split multi-stage mixing water softening valve of the present invention includes a valve body, and the valve body includes an upper valve body 12 and a lower valve body 9 .

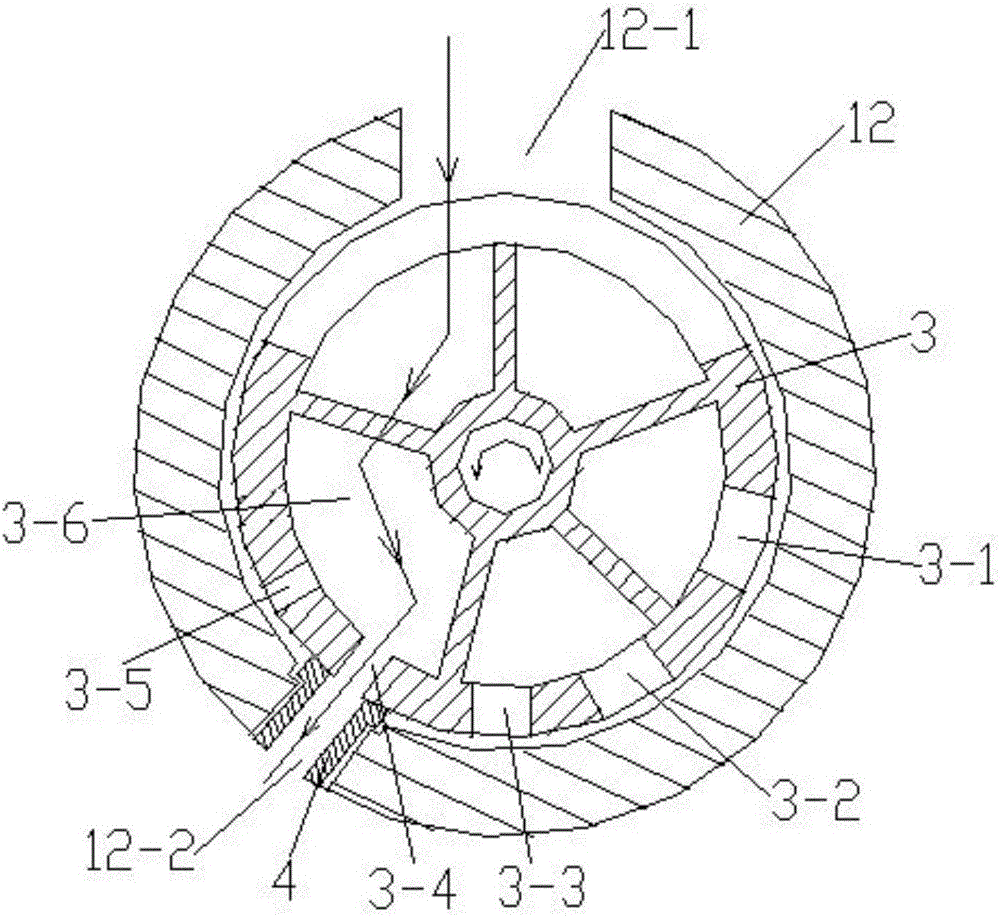

[0027] The top of the upper valve body 12 is provided with a valve body water inlet 12-1, a valve body water outlet 12-2 and a valve inner cavity 12-6, and the valve inner cavity 12-6 is provided with a valve core 3, and the top of the valve core 3 is connected with the valve body. The rotary handle 1 at the upper end of the valve inner chamber 12-6 is connected. The lower part of the valve core 3 is provided with a cavity 3-6, one side of the cavity 3-6 communicates with the water inlet 12-1 of the valve body, and the other side of the cavity 3-6 is provided with 5 mixing ports of different sizes, which are respectively mixing ports. Water outl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com