System and method for real-time prediction of calorific value of circulating fluidized bed domestic waste incineration boiler

A domestic waste incineration and circulating fluidized bed technology, which is applied in the direction of combustion method, incinerator, combustion type, etc., can solve the problems that the characteristics are difficult to determine, and it is difficult to be competent for real-time and uninterrupted calorific value monitoring work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

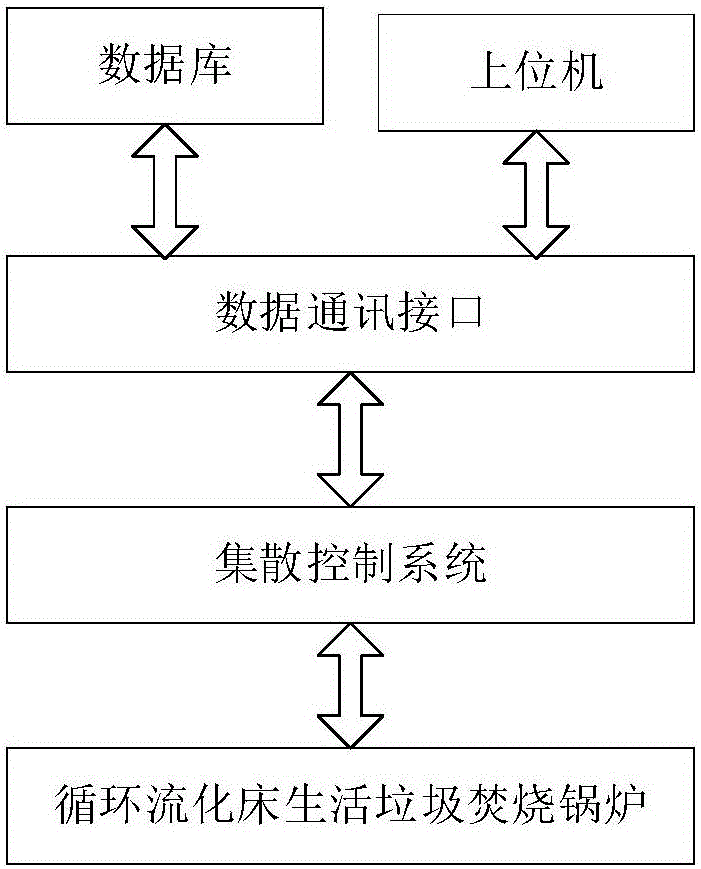

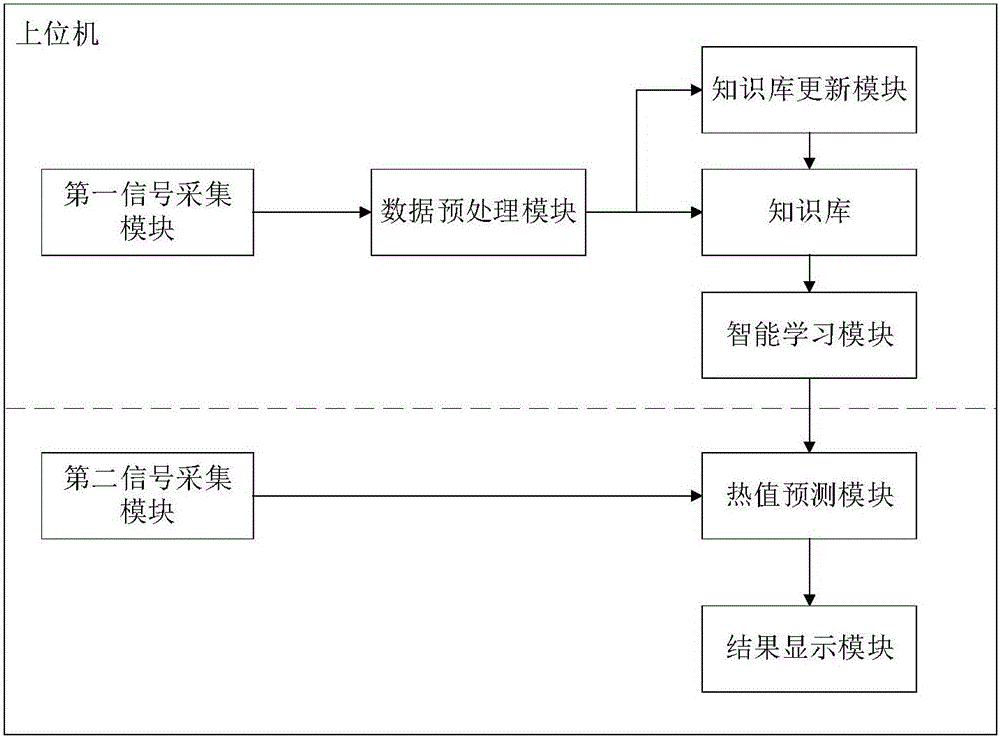

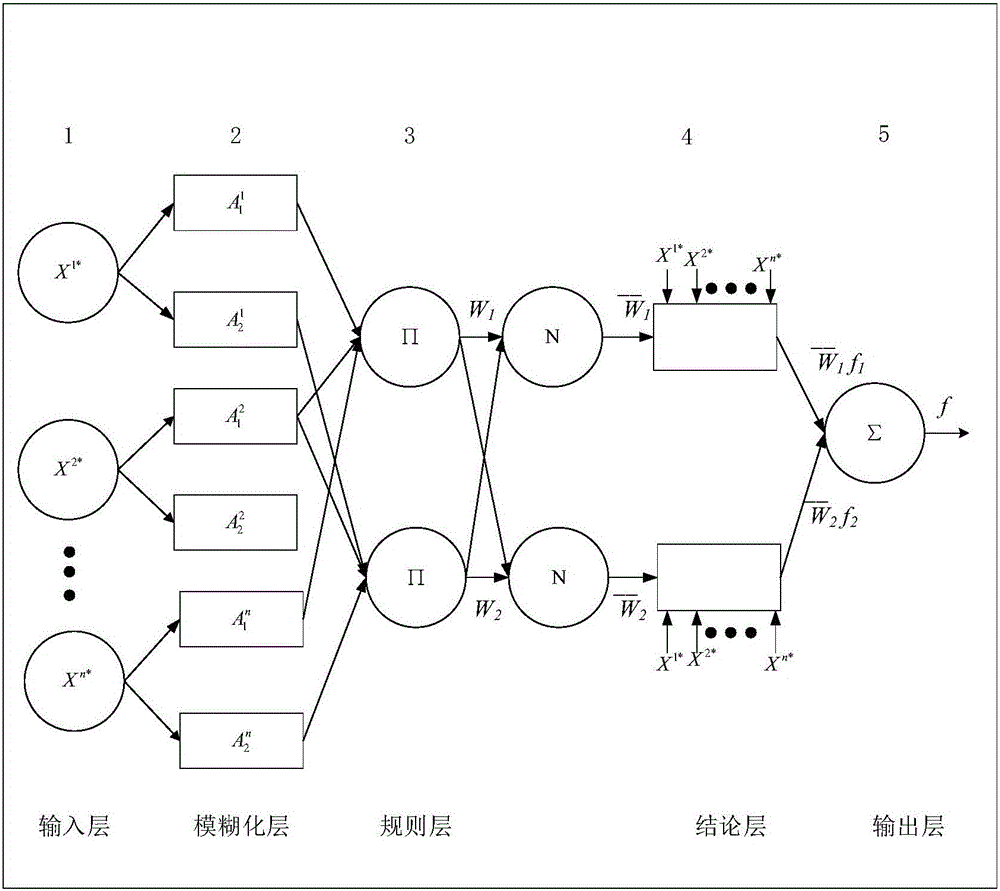

[0125] refer to figure 1 , figure 2 , image 3 , Figure 4 , a circulating fluidized bed domestic waste incineration boiler provided by the present invention provides a real-time prediction system for the calorific value of waste in the furnace, including a circulating fluidized bed domestic waste incineration boiler, a distributed control system for the operation control of the boiler, a data communication interface, and a database and host computer. The database reads data from the distributed control system through the data communication interface, and is used for training, learning and testing of the upper computer. The upper computer performs data exchange with the distributed control system through the data communication interface. The upper computer includes offline learning, verification and Prediction part of the calorific value of online furnace waste. The offline learning and verification part includes:

[0126] The first signal acquisition module: this module...

Embodiment 2

[0186] refer to figure 1 , figure 2 , image 3 , Figure 4 , a method for predicting the calorific value of waste in a circulating fluidized bed domestic waste incineration boiler provided by the present invention, the method includes the following steps:

[0187] 1) Select variables and collect samples: Utilize the mechanism of domestic waste incineration in circulating fluidized bed boilers, select input variables for the prediction model of waste calorific value, and consider the following strategies when selecting: a) Fuel into the furnace is composed of coal and garbage Yes, for the same kind of coal, the calorific value is relatively stable, so the operating personnel will take the current coal supply into consideration when judging the calorific value of domestic waste entering the furnace; b) When the operating personnel are stoking the furnace, there is an important The main task is to control the bed temperature between 850°C and 950°C. The change of the bed temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com