Flexible detecting mechanism

A detection mechanism and flexible technology, applied in the field of automatic glass processing equipment, can solve problems such as inaccurate measurement, measurement errors, and visual errors, and achieve the effects of large contact area, reduced detection errors, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

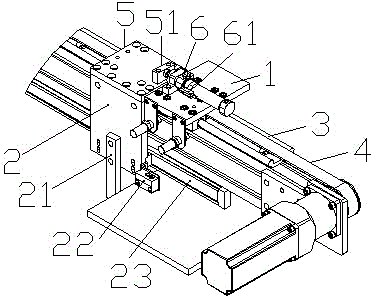

[0009] Reference figure 1 , A flexible detection mechanism, comprising a power slide 1, a measuring slide 2, a guide rail 3, and a timing belt 4. The power slide 1 and the measuring slide 2 are each movably connected to the guide rail 3 through a sliding block. The belt 4 is connected, the top of the measuring slide 2 is vertically installed with a flat plate 5, the top of the power slide 1 is installed with a buffer cylinder 6, and the buffer cylinder 6 on the top of the power slide 1 is connected to the flat plate 5. The upper cylinder connecting seat 51 is connected, the middle of the front surface of the measuring slide 2 is radially and vertically installed with a measuring clip 21, one side of the measuring slide 2 is horizontally installed with a photoelectric sensor 22, and the measuring slide 2 A linear displacement sensor 23 is horizontally installed on the back side, and a magnetic switch 61 is installed on one side of the buffer cylinder 6.

[0010] The power skatebo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com