Calibration method of engine flowmeter

A calibration method and flowmeter technology, applied in liquid/fluid solid measurement, measurement devices, instruments, etc., can solve problems such as inability to engine flowmeter, calibration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

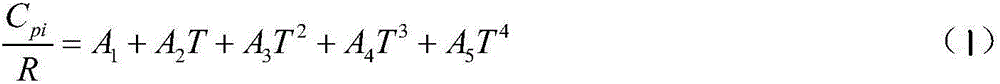

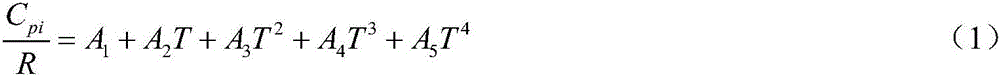

[0055] A calibration method for an engine flowmeter, the steps are as follows

[0056] 1. Establish the same calibration conditions as the use environment

[0057]The engine generally works in an environment where the total temperature of the incoming flow is above 1000K, and it is necessary to use a wind tunnel to establish calibration conditions consistent with the operating environment. The wind tunnel uses hydrogen and oxygen-enriched air combustion heating to obtain the required test flow. The simulated flow parameters include: total temperature, total pressure and Mach number, and choose different oxygen-enriched pipe gas distribution parameters and oxygen-enriched throats. Diameter, squeeze hydrogen supply pressure and hydrogen throat diameter and nozzle, can get different test flow conditions.

[0058] Second, the establishment of engine flow measurement system

[0059] Place two channel flowmeters respectively in the downstream of the oxygen-enriched air throat and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com