Movable platform calibration device and calibration method based on visual recognition

A mobile platform and calibration device technology, applied in image data processing, instruments, calculations, etc., can solve problems affecting the stability and reliability of operation, achieve the effect of improving stability and reliability, and reducing research and development costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

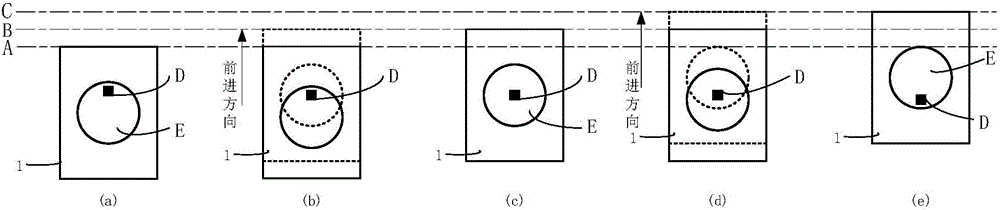

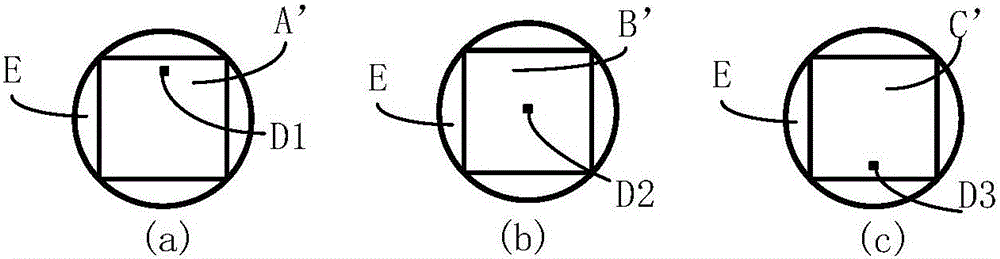

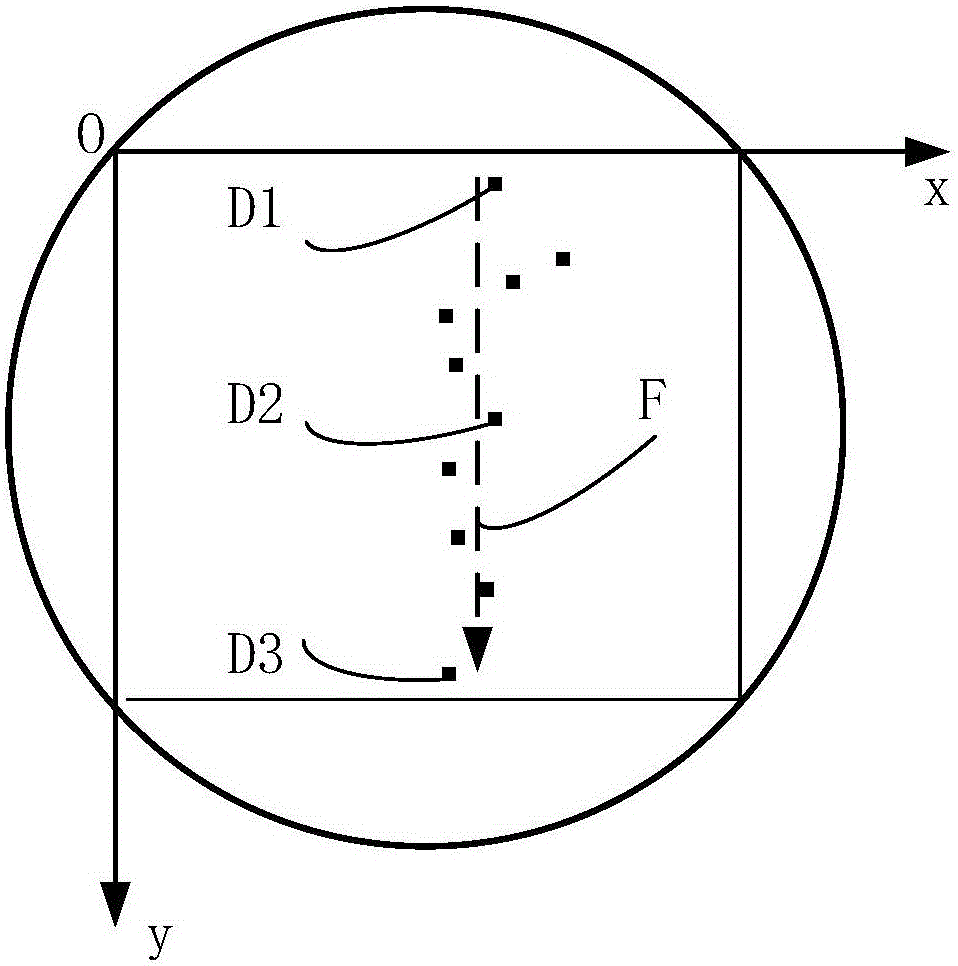

[0027] The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

[0028] like figure 1 As shown, the calibration device of the present invention includes: a camera unit and a calculation unit.

[0029] The camera unit acquires the image and records the coordinates of the marked points in the image. The marked points are placed on the working plane of the movable platform and are located within the field of view of the camera unit during the movement of the movable platform. The camera unit is installed on the movable Near the center of the platform, facing the working plane, use the calibration board and the camera calibration tool in matlab to calibrate the internal parameters, external parameters, and distortion parameters. The marking point can be any distinguishing background, and can be identified and uniquely determined in the image, that is, the point has a definite unique coordinate in an ima...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com