An integrated device for inserting alkaline batteries into the ring and applying sealing agent

An alkaline battery and sealing agent technology, applied in the direction of dry batteries, etc., can solve the problems of reducing non-process waiting time, a large number of production line equipment, and large space occupied by equipment, so as to reduce non-process waiting time, simplify the number of equipment, and structural design reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

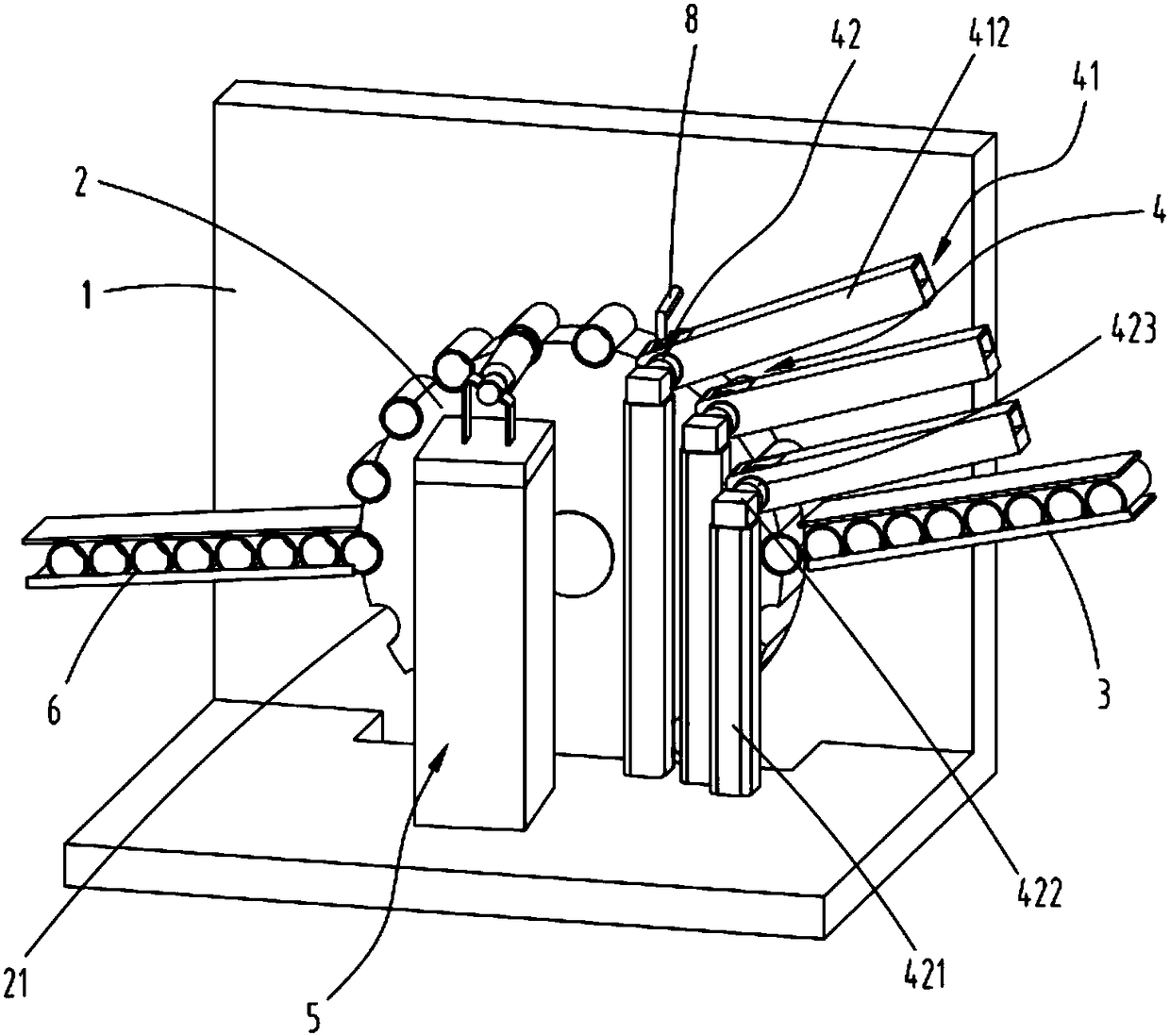

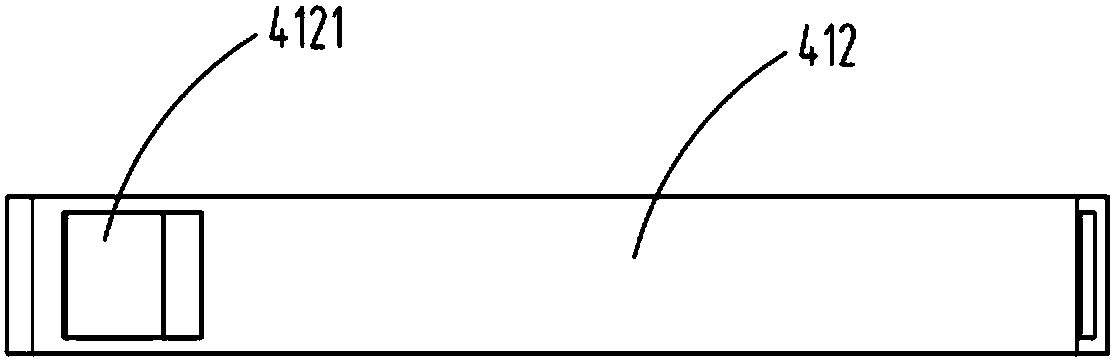

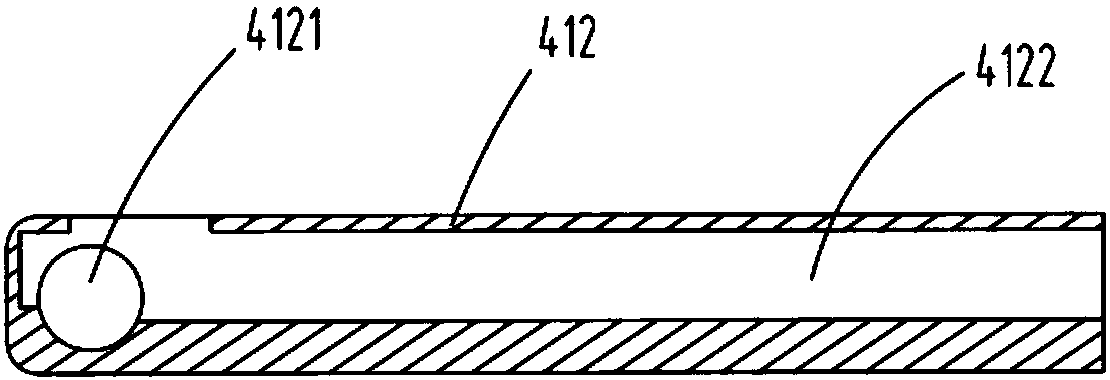

[0038] like Figure 1 to Figure 3As shown, the present invention provides an integrated device for inserting alkaline batteries into the ring and applying a sealing agent, which includes a frame 1, a turntable 2 vertically installed on the frame 1, a feeding channel 3, a ring-entry mechanism 4, and a sealing port The agent mechanism 5 and the discharge channel 6, the feed channel 3 and the discharge channel 6 are respectively arranged correspondingly along the feed direction and the discharge direction of the turntable 2, and several holes are uniformly arranged on the circumferential edge of the turntable 2 for positioning The card slot 21 of the steel shell, the sealing agent mechanism 5 is arranged behind the ring-entry mechanism 4, the ring-entry mechanism 4 includes a carbon ring conveying mechanism 41 and a pushing mechanism 42, and the carbon ring conveying mechanism 41 includes a carbon ring distribution tray 411 and three carbon ring conveying passages 412 correspondi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com