Distributor device and method for feeding rod processing machine in tobacco industry with stream of products made of fibrous material

A fiber material and distribution device technology, applied in tobacco, application, cigarette manufacturing, etc., can solve problems such as height and depth of problems, uneven filling of wells scenes, quality parameters of products to be produced, and achieve compact and safe transfer and uniform distribution. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

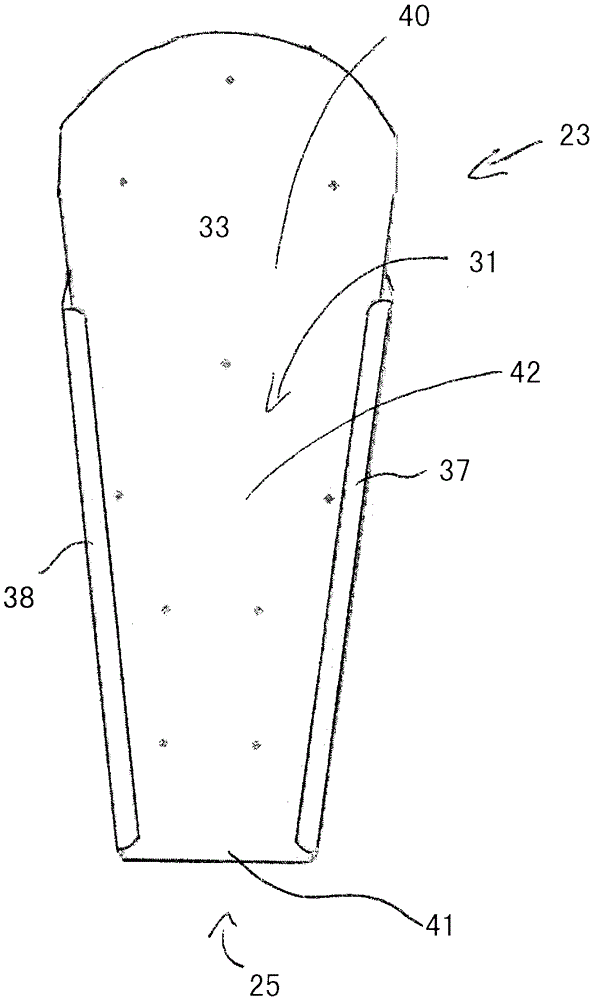

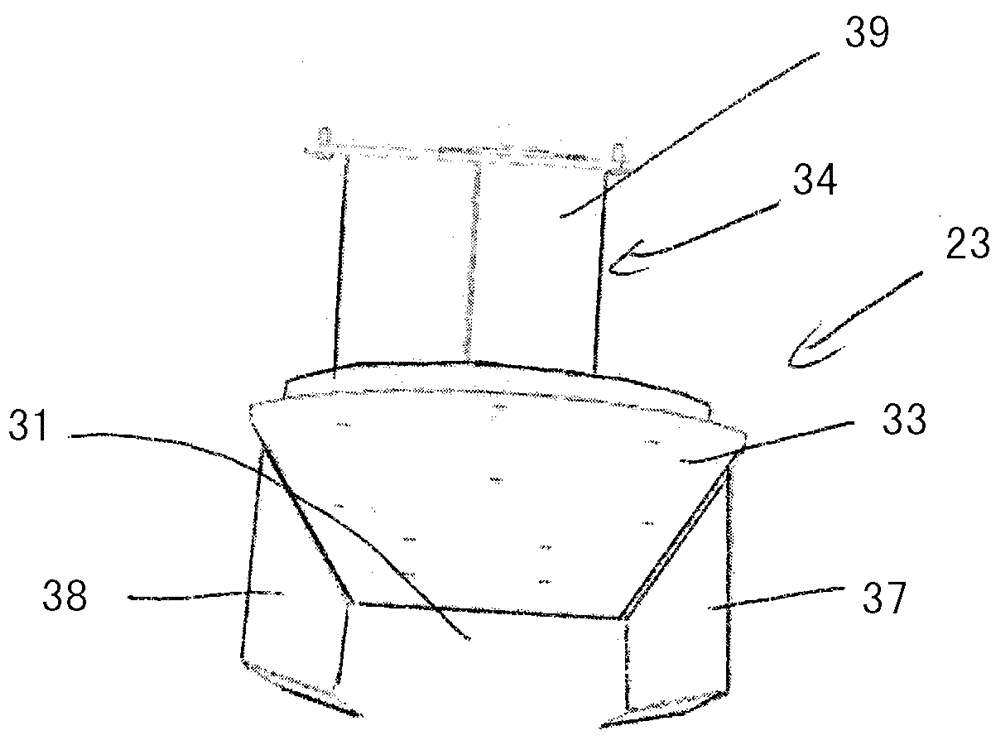

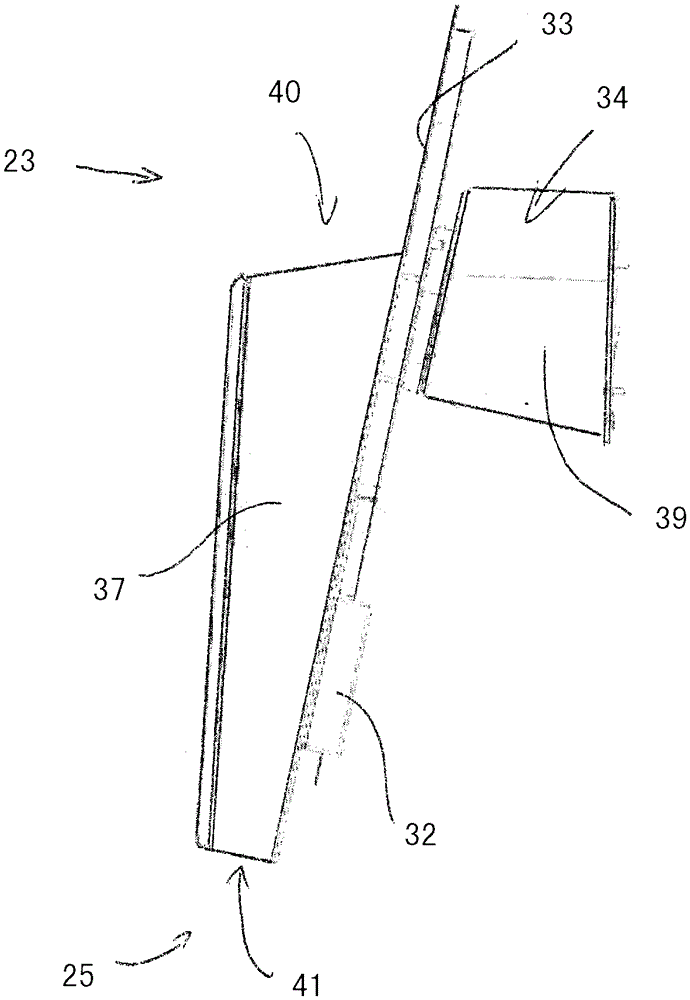

[0030] The dispensing device shown in the figures is used for collating tobacco fiber material and forming tobacco rods. Obviously, the dispensing device according to the present invention is also constructed and arranged for arranging filter fiber material for forming a filter rod; and for arranging a fiber mixture composed of tobacco fiber material and filter fiber material for forming a hybrid rod for forming multiple strips of the aforementioned type.

[0031] exist figure 1 The distributing device 10 shown in includes a supply device 18 for feeding the fibrous material to a distribution unit 17 for charging a not-shown sliver of the tobacco processing industry with a product flow of fibrous material machine, the product flow at the end of the distribution device 10 is fed by a rear distribution unit 17 and at least one stuffer shaft 13 to at least one suction rod conveyor 16 for constituting a rod formed of fibrous material.

[0032] The dispensing device 10 is characte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com