A ceramic hollow fiber membrane filter element and its components

A fiber membrane and membrane module technology, applied in the field of ceramic hollow fiber membrane filter element and its components, can solve the problems of difficult sealing and poor strength, and achieve the effect of high filling area, high permeation flux, and broadening the application field of membrane

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

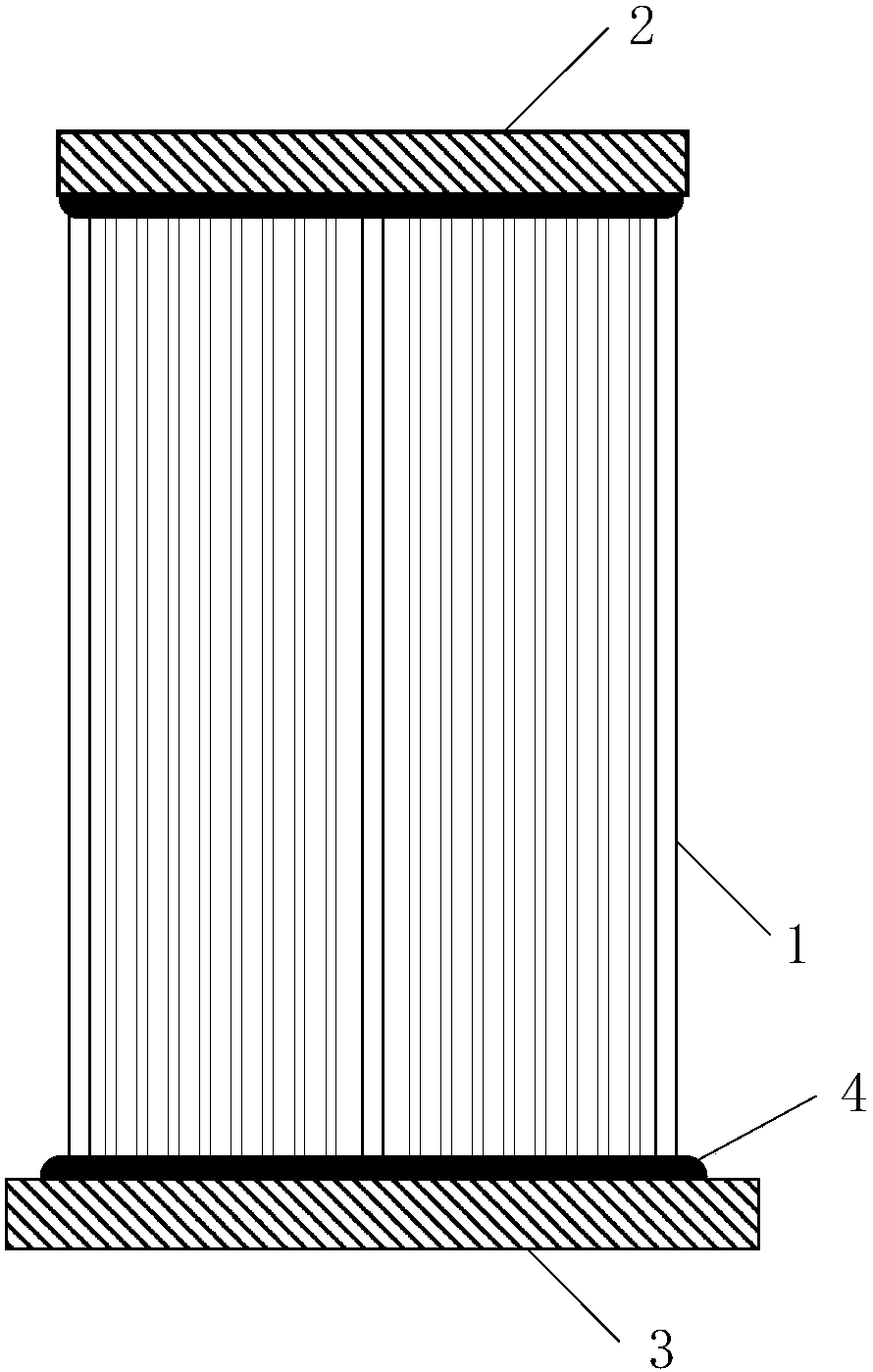

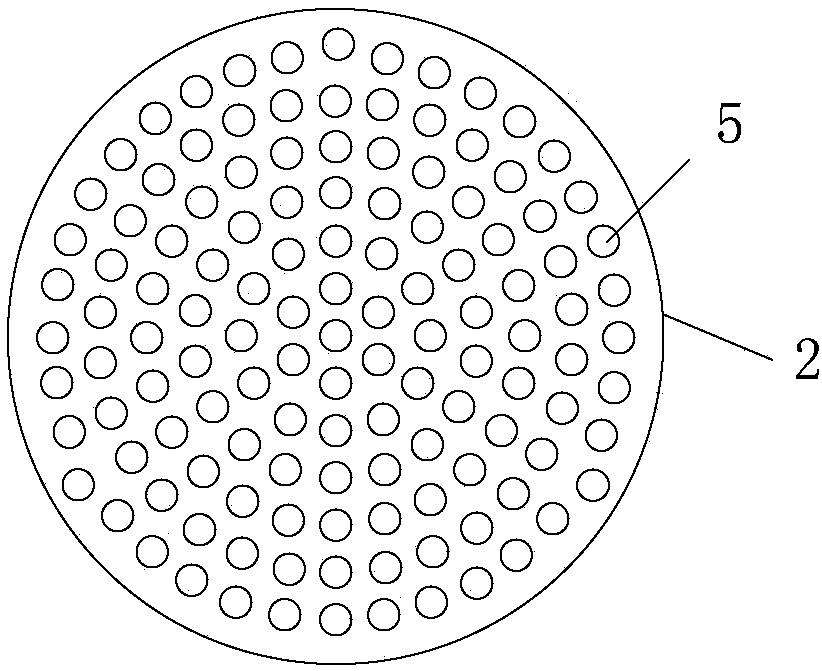

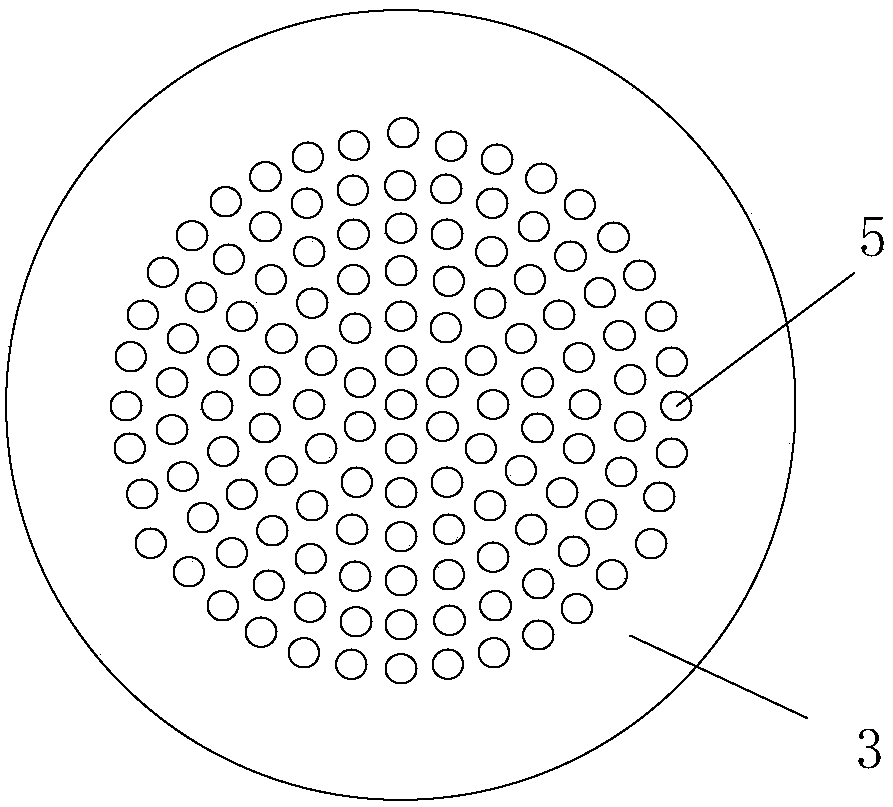

[0058] like figure 1 As shown, the ceramic hollow fiber molecular sieve membrane filter element consists of 58 hollow fiber molecular sieve membranes 1 with a single NaA channel, a porous base 3 and a porous cover plate 2 . The hollow fiber NaA molecular sieve membrane tube is 20cm long, and the carrier is made of α-Al 2 O 3 Composition, the outer diameter is 3mm, the average pore diameter is 0.8 μm, and the porosity is 35%. Both the porous base and the porous cover are circular, with a thickness of 2 cm, containing 58 membrane holes, and the material is ceramic alumina ceramics. One end of the hollow fiber molecular sieve membrane tube is inserted into the membrane hole of the ceramic base through the ceramic cover plate, sealed by pouring ceramic glue, and the membrane cover plate is opened. The closed hole at the other end is sealed with the membrane hole of the porous cover plate to form a hollow fiber molecular sieve membrane filter element. The distance between the me...

Embodiment 2

[0061] The ceramic hollow fiber molecular sieve membrane filter element consists of 89 T-shaped single-channel ceramic hollow fiber molecular sieve membranes 1, a porous base, and a porous cover plate. The hollow fiber T-type molecular sieve membrane tube is 30cm long, the carrier is composed of YSZ, its outer diameter is 3.6mm, the average pore diameter is 0.6μm, and the porosity is 45%. Both the porous base and the porous cover are circular, with a thickness of 1.5 cm, containing 89 membrane holes, and the material is polytetrafluoroethylene. One end of the hollow fiber molecular sieve membrane tube is inserted into the membrane hole of the polytetrafluoroethylene base through the polytetrafluoroethylene cover plate, and epoxy resin is poured to seal it, and the membrane base is opened. The closed hole at the other end is sealed with the membrane hole of the porous cover plate to form a hollow fiber molecular sieve membrane filter element, and the distance between the membra...

Embodiment 3

[0064] The ceramic hollow fiber molecular sieve membrane filter element includes 126 single-channel ceramic hollow fiber MFI molecular sieve membrane tubes, a porous base, and a porous cover plate. The hollow fiber MFI molecular sieve membrane tube is 40cm long, and the carrier is made of TiO 2Composition, the outer diameter is 2mm, the average pore diameter is 1.0μm, and the porosity is 50%. Both the porous base and the porous cover are circular with a thickness of 1.5 cm and contain 126 membrane holes. One end of the hollow fiber MFI molecular sieve membrane tube is inserted into the membrane hole of the ceramic base through the ceramic cover plate, sealed with epoxy resin, and the membrane cover plate is opened. The closed hole at the other end is sealed with the membrane hole of the porous cover plate to form a hollow fiber molecular sieve membrane filter element, and the distance between the membrane tubes is 4mm.

[0065] The ceramic hollow fiber molecular sieve membra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com