Preparation method of integrated multi-root ceramic hollow fiber molecular sieve membrane

An integrated, molecular sieve technology, applied in chemical instruments and methods, membranes, membrane technology, etc., can solve problems such as difficult sealing and poor strength, and achieve the effects of broadening application fields, increasing membrane production, and improving synthesis efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

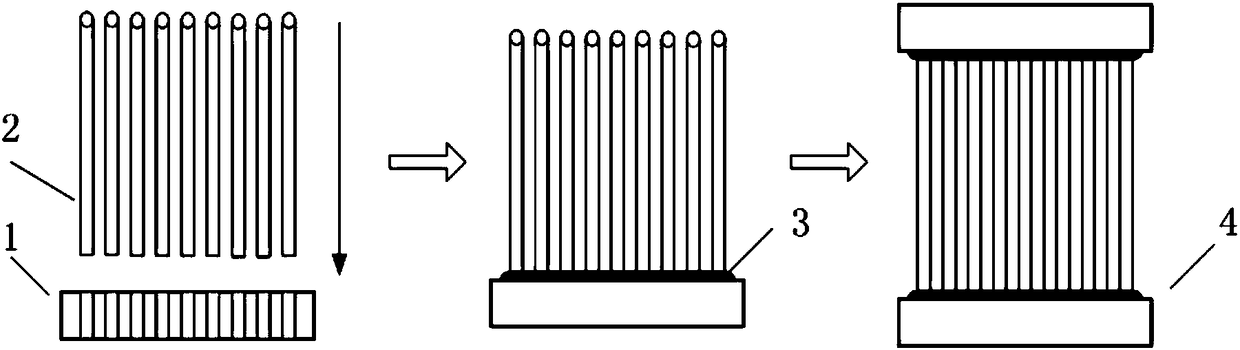

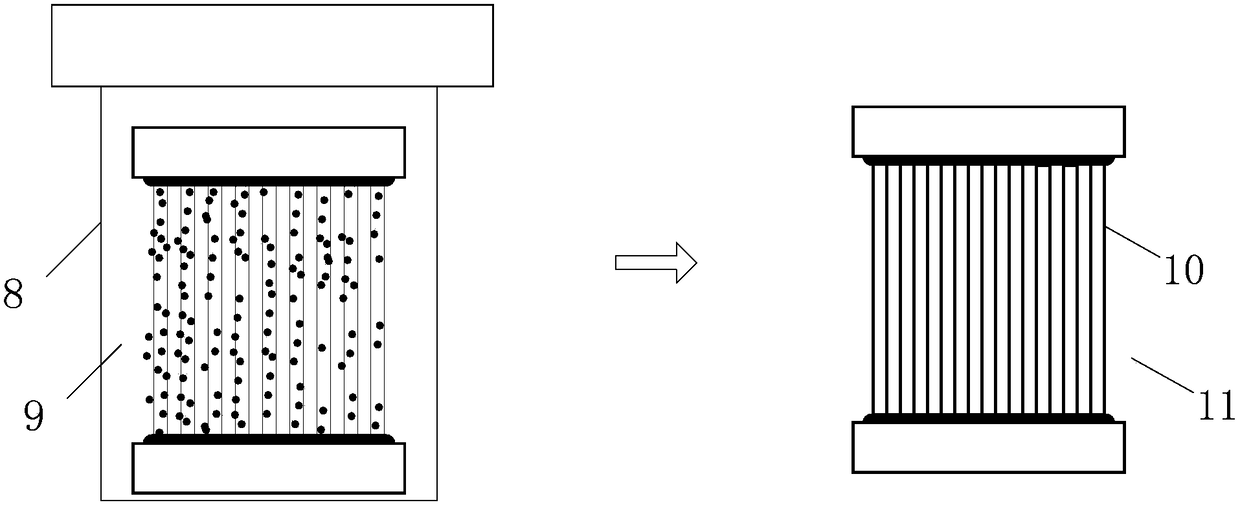

[0034] The invention provides an integrated method for preparing multiple ceramic hollow fiber molecular sieve membranes, wherein the ceramic hollow fiber molecular sieve membrane is composed of a ceramic hollow fiber carrier and a molecular sieve membrane layer on the outer surface thereof. The specific steps of the method are as follows:

[0035] Such as figure 1 As shown, firstly, a multi-channel base 2 needs to be prepared, and holes are distributed on the multi-channel base 2, and the material of the multi-channel base can be polytetrafluoroethylene, ceramics or metal. Inserting one end of the hollow fiber carrier 1 can play the role of fixing and sealing the hollow fiber carrier 1. The diameter of the hole is preferably slightly larger than the outer diameter of the hollow fiber carrier. On the one hand, the carrier can be better fixed, and on the other hand On the one hand, it is convenient to prevent the sealing material from flowing into the gap during the subsequent...

Embodiment 1

[0046] The preparation method of an integrated hollow fiber NaA molecular sieve membrane, the specific steps are as follows:

[0047] (a) Insert one end of the hollow fiber carrier into a circular porous base with 69 channels. The contact part between the base and the hollow fiber carrier is sealed with ceramic sealant, and the other end is inserted into the same base. After sealing and sintering, an integrated Multiple hollow fiber carrier assemblies.

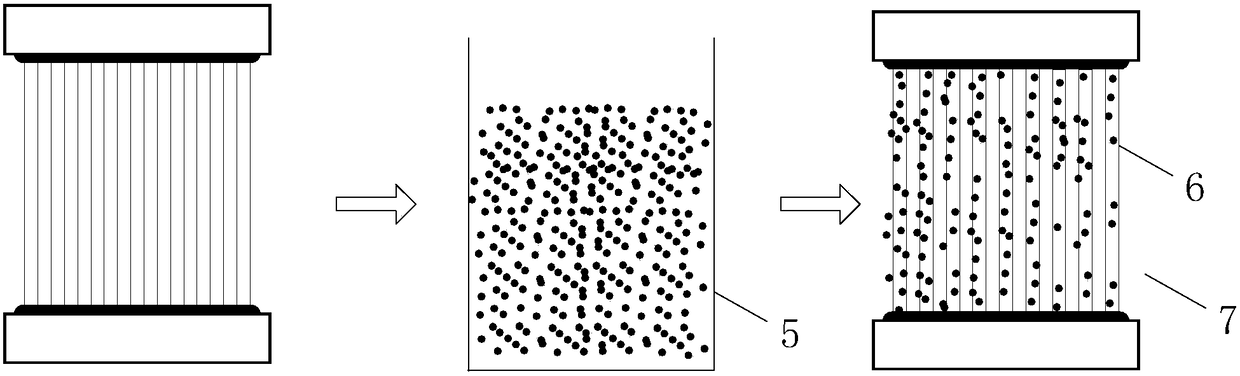

[0048] (b) Using special crystal coating equipment, the integrated multi-hollow fiber carrier assembly is immersed in the pre-prepared NaA seed crystal solution by dipping and pulling, and the seed crystal concentration is 1%. Dipping time 5 seconds. After drying, a carrier assembly with a uniform seed layer is obtained covering the surface of the seed layer carrier such as Figure 5 shown.

[0049] (c) Referring to the synthesis ratio adopted in the patent CN101381087B, prepare the synthesis solution for preparing NaA mole...

Embodiment 2

[0051] The preparation method of an integrated hollow fiber NaA molecular sieve membrane, the specific steps are as follows:

[0052] (a) Insert one end of the hollow fiber carrier into a square porous base with 91 channels. The contact part between the base and the hollow fiber carrier is sealed with silicone, and the other end is inserted into the same base. After sealing and drying, an integrated Multiple hollow fiber carrier assemblies.

[0053] (b) Using special crystal coating equipment, through vacuum suction, immerse the integrated multi-root hollow fiber carrier assembly into the pre-prepared seed crystal solution with a seed concentration of 1% NaA, and adjust the pressure on both sides of the carrier through the vacuum system. The difference is 0.01MPa, and the suction time is 5 seconds. After drying, a carrier assembly with a uniform seed layer is produced.

[0054] (c) Referring to the synthesis ratio used in the patent CN101381087B, prepare the synthesis liquid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com