Perforated box machining device

A technology of turning processing and box body, which is applied in the direction of positioning devices, metal processing equipment, metal processing machinery parts, etc., can solve the problems of inaccurate processing, low production efficiency, offset, etc. High, the effect of ensuring the parallelism of the axis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

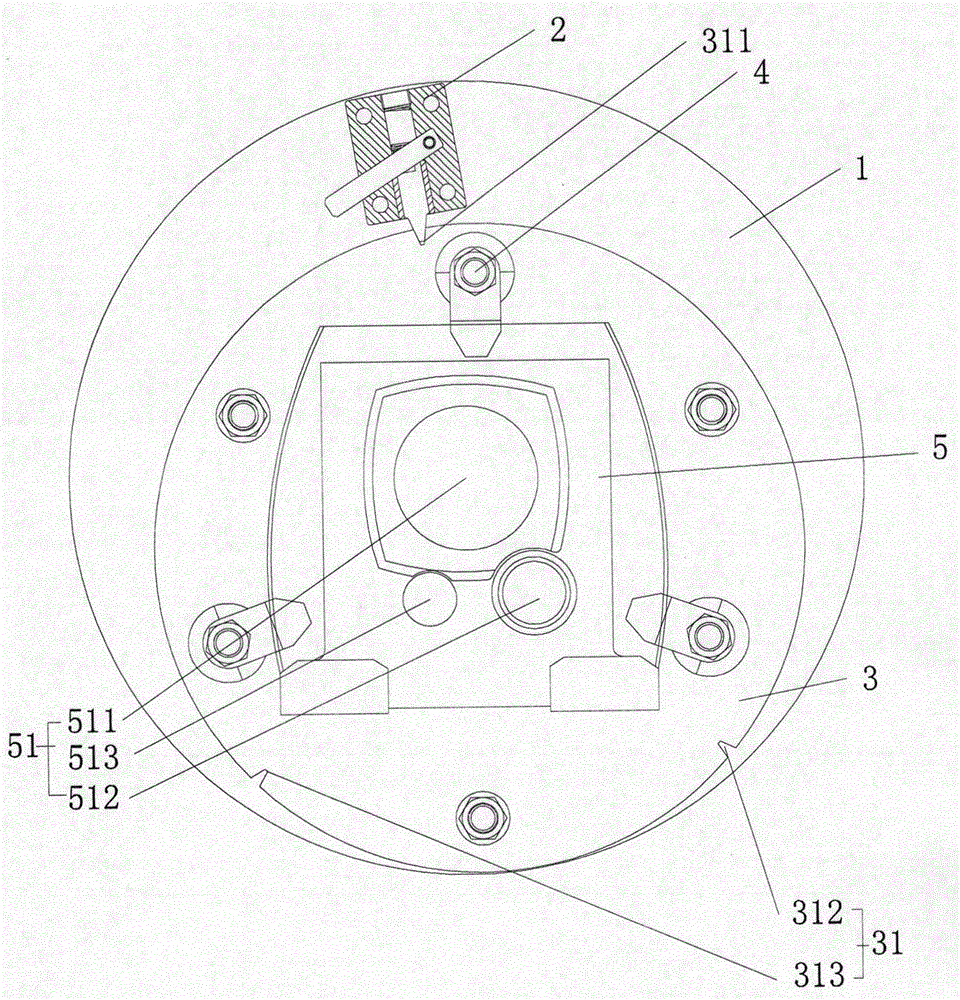

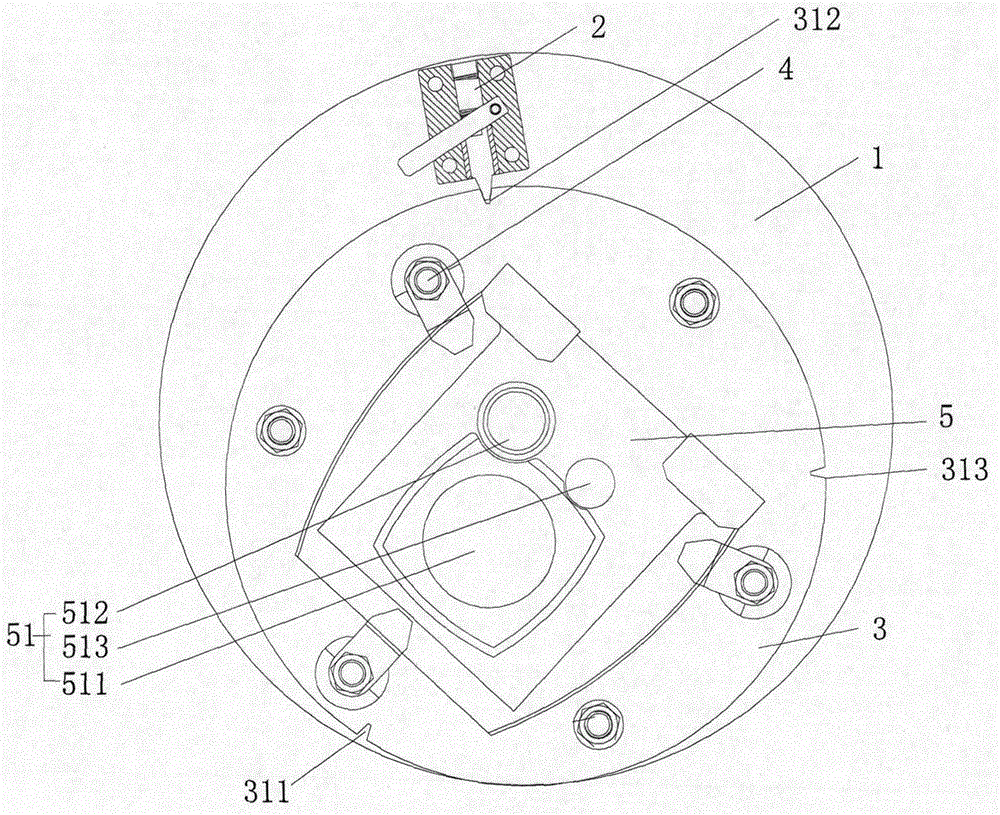

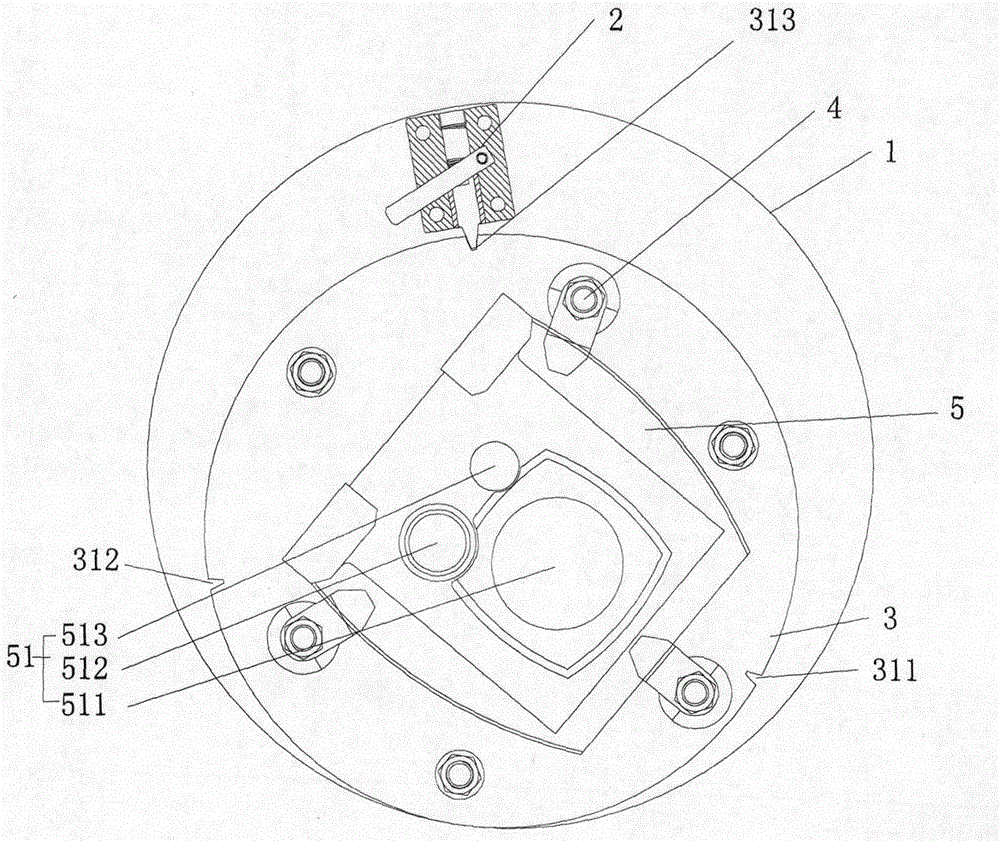

[0027] refer to Figure 1 to Figure 6 The embodiments of the present invention will be further described.

[0028] A porous box turning device, comprising a fixed chassis 1 and a movable disk 3, the movable disk 3 is eccentrically arranged on the fixed chassis 1, and the movable disk 3 is provided with a pressing plate device 4 for fixing the gear box 5; The fixed chassis 1 is provided with a positioning device 2 for fixing the movable disk 3 during processing.

[0029] In this way, a plurality of holes 51 to be processed with different sizes on the gear box can be processed through one clamping, which overcomes the inaccurate processing caused by positioning errors caused by multiple clampings, and also realizes that the processing can be completed on one operating table. The processing of multiple holes 51 to be processed in the gear box 5 greatly reduces the waste of manpower, material and financial resources, improves work efficiency, conforms to mechanized production, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com