A double-end processing and clamping device for thin-walled metal tubes capable of automatic reversing

A clamping device and automatic reversing technology, applied in the direction of metal processing, metal processing equipment, metal processing machinery parts, etc., can solve the problem of increasing the process of unloading, collecting and loading materials, inconvenient equipment management and maintenance, and increasing production Process and other issues, to achieve the effect of simple and compact structure, convenient double-end processing, and improve processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with accompanying drawing:

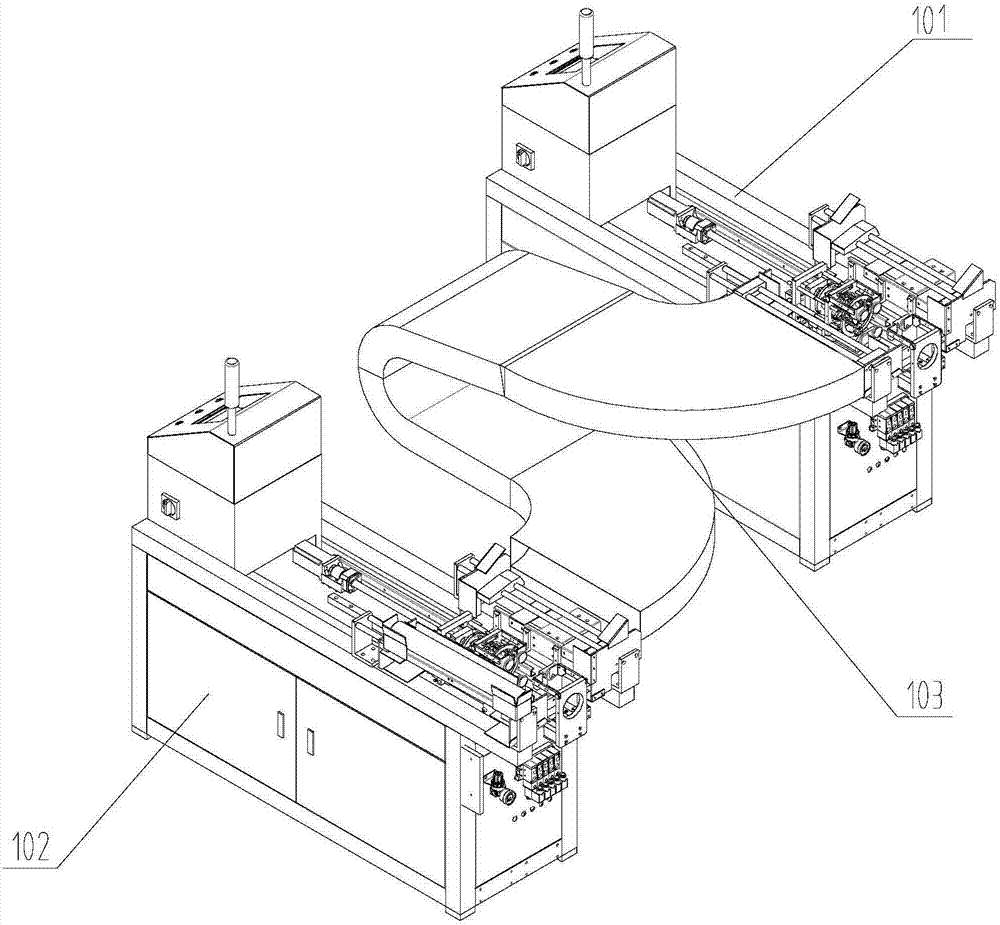

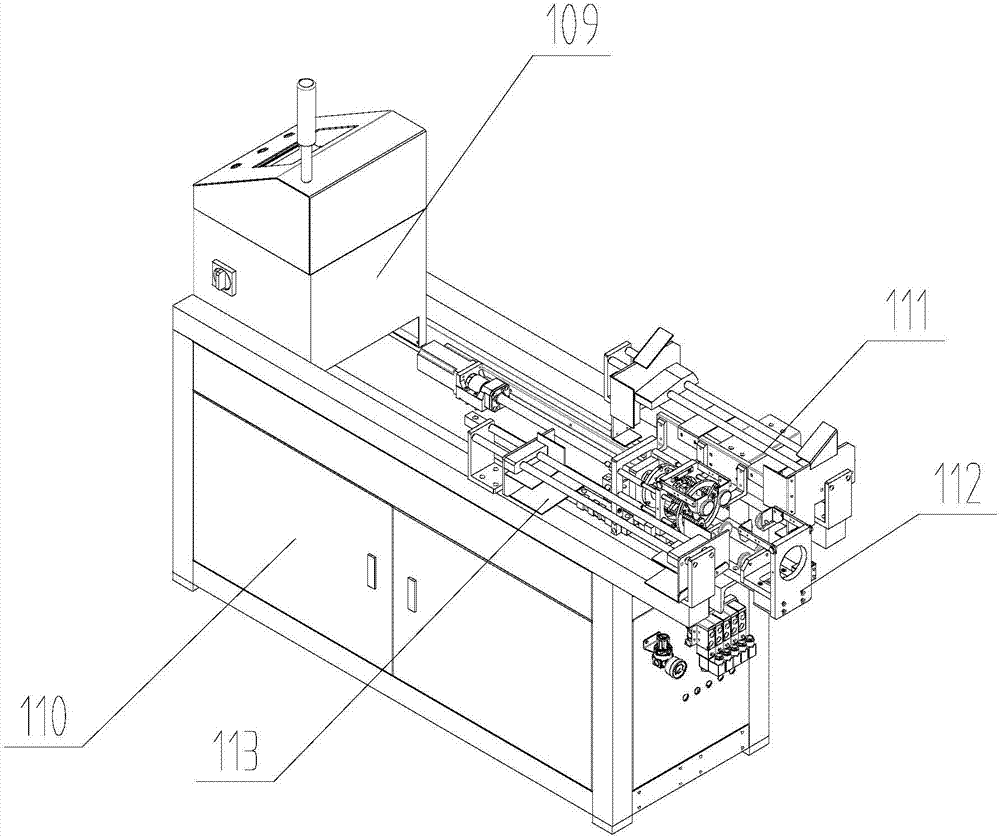

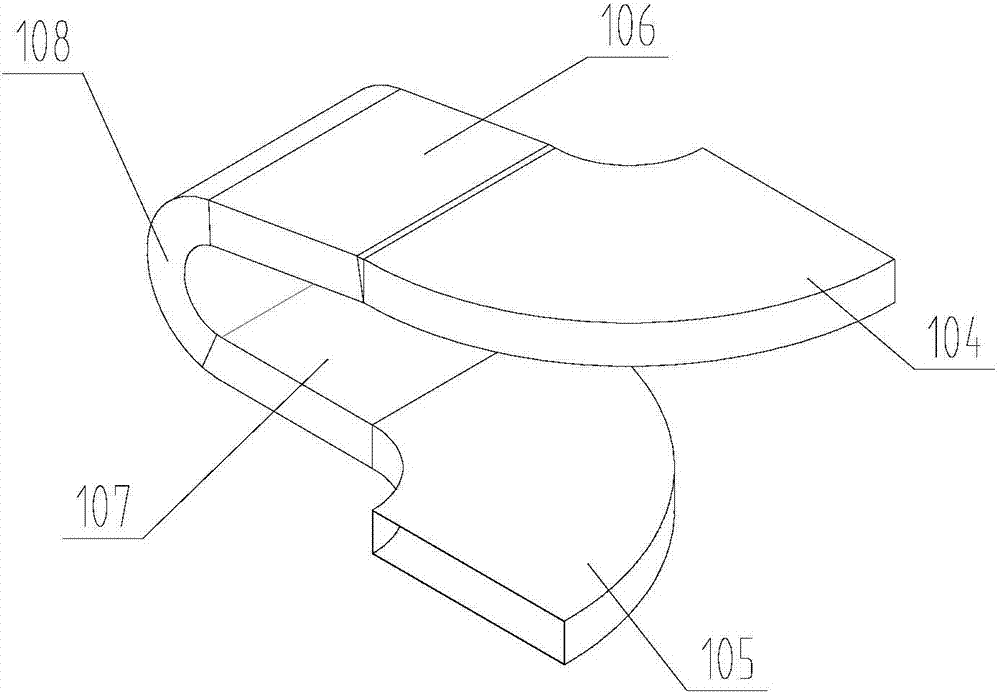

[0034] like Figure 1-7 As shown, a thin-walled metal pipe double-end processing clamping device capable of automatic reversing includes a first clamping feeding device 101 and a second clamping feeding device 102 arranged in parallel, and a The reversing feed track 103 between the feeding device and the second feeding and clamping device, the structure of the first clamping and feeding device 101 and the second clamping and feeding device 102 is exactly the same, and the installation height of the first clamping and feeding device 101 is Higher than the installation height of the second clamping feeding device 102, the reversing feeding track 103 includes a first arc track 104, a U-shaped track and a second arc track 105, and the inlet of the first arc track 104 is connected The outlet of the first clamping and feeding device 101, the outlet of the first arc track 104 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com