Cooling device for machine tool and parts

A technology for cooling devices and parts, applied in metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc., can solve problems such as loss, deformation of processed parts, and impact on part size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

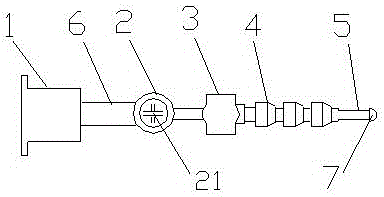

[0009] Such as figure 1 As shown, a cooling device for machine tool components is composed of a gas booster pipe 1, an electromagnetic one-way valve 2, a regenerator 3 and an air outlet hose 4. The gas booster tube 1 and the electromagnetic one-way The valves 2 are connected through a high-pressure casing 6, and the electromagnetic one-way valve 2 and the outlet hose 4 are connected through a straight pipe, and the straight pipe between the electromagnetic one-way valve 2 and the outlet hose 4 is installed with Regenerator 3.

[0010] Specific implementation: a manual valve 21 is installed outside the electromagnetic one-way valve 2 .

[0011] A medium pressure sleeve 5 is installed at the end of the outlet hose 4, and a gas condenser 7 is installed at the end of the medium pressure sleeve 5.

[0012] Finally, it should be noted that: the above embodiments are only used to illustrate the present invention rather than limit the technical solutions described in the present inv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com