High-content aerogel master batch and preparation method thereof

An airgel, high-content technology, applied in the field of airgel, can solve the problems of high hardness, poor toughness, poor spinning quality, etc., and achieve the effect of high airgel content, high product processability, and no defects in appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The present invention discloses a high-content aerogel masterbatch and a preparation method thereof, wherein the preparation method of the high-content aerogel masterbatch includes the following steps:

[0029] S1: In parts by weight, 20-30 parts of aerogel and 6-26 parts of dispersant and / or coupling agent are prepared;

[0030] S2: Put the above materials into a high-speed mixer, mix at a low speed of 50 rpm-100 rpm for 3 minutes-5 minutes, and then adjust to a speed of 300 rpm-600 rpm Mixing at high speed for 3 minutes to 5 minutes to obtain mixed materials;

[0031] S3: Put 44 parts-74 parts of the carrier resin together with the mixed material in step S2 into the high mixer, first mix at a low speed of 50 r / min-100 r / min for 2 minutes-5 minutes, and then Adjusted to a high rotational speed of 300 rpm to 600 rpm and mixed for 5 minutes to 10 minutes to obtain a master batch;

[0032] S4: Introduce the masterbatch obtained in step S3 into a heat-preserving internal...

Embodiment 1

[0044] It includes the following steps:

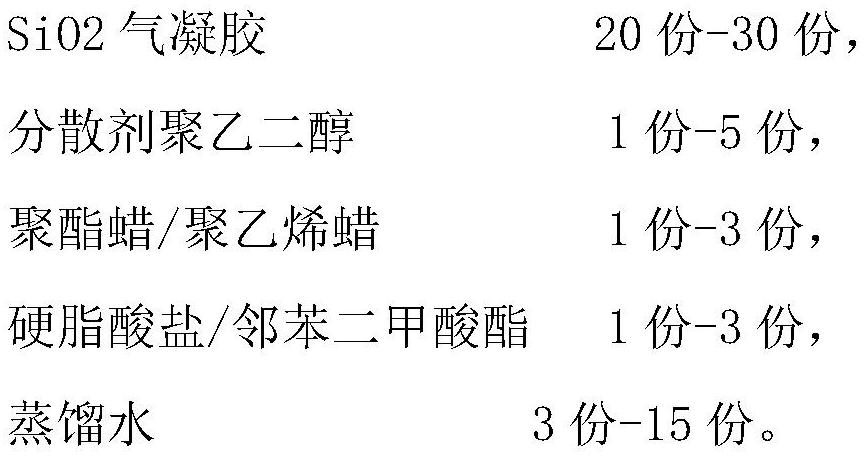

[0045] S1: In parts by weight, equipped with the following materials:

[0046]

[0047] S2: Put the above materials into a high-speed mixer, mix at a low speed of 50 rpm-100 rpm for 3 minutes-5 minutes, and then adjust to a speed of 300 rpm-600 rpm Mixing at high speed for 3 minutes to 5 minutes to obtain mixed materials;

[0048] S3: Put 66 parts of PBT resin powder together with the mixed material in step S2 into the high mixer, first mix at a low speed of 50 rpm to 100 rpm for 2 minutes to 5 minutes, and then adjust Mixing for 5 minutes to 10 minutes at a high rotational speed of 300 rpm to 600 rpm to obtain a master batch;

[0049] S4: Introduce the masterbatch obtained in step S3 into a heat-preserving internal mixer, where the internal mixing temperature in the heat-preserving internal mixer is 200°C-250°C, and the internal mixing is 20-50 minutes;

[0050] S5: take out the master batch after banburying, after cooling, pulver...

Embodiment 2

[0053] It includes the following steps:

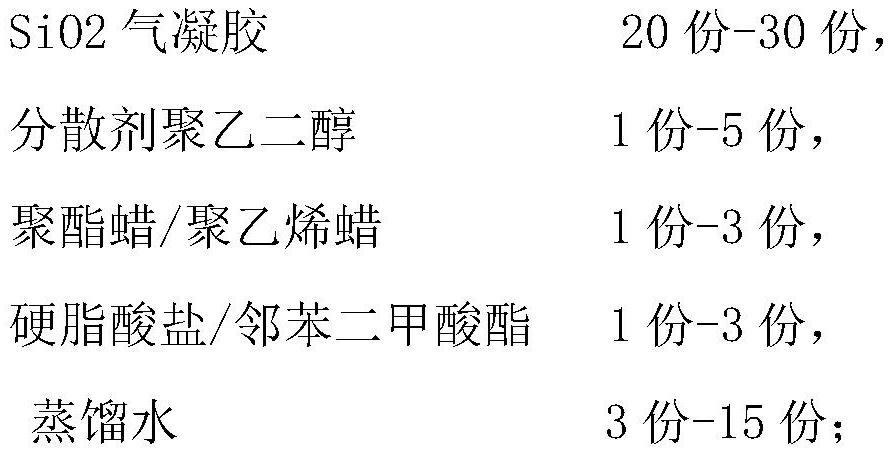

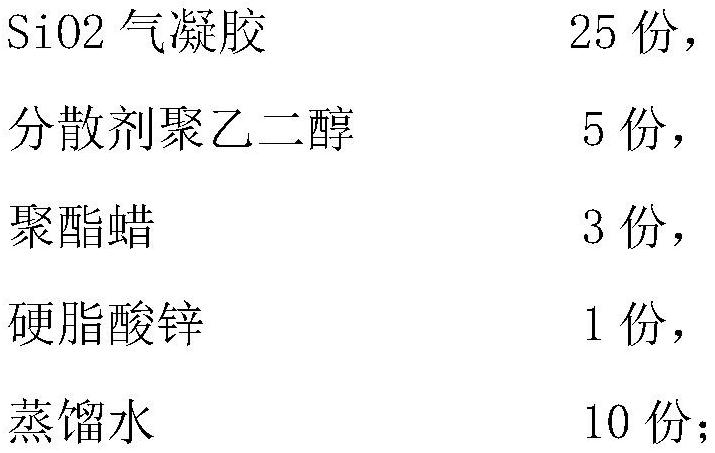

[0054] S1: In parts by weight, equipped with the following materials:

[0055]

[0056] S2: Put the above materials into a high-speed mixer, mix at a low speed of 50 rpm-100 rpm for 3 minutes-5 minutes, and then adjust to a speed of 300 rpm-600 rpm Mixing at high speed for 3 minutes to 5 minutes to obtain mixed materials;

[0057] S3: Put 60 parts of the PBT resin powder together with the mixed material in step S2 into the high mixer, first mix at a low speed of 50 rpm to 100 rpm for 2 minutes to 5 minutes, and then adjust Mixing for 5 minutes to 10 minutes at a high rotational speed of 300 rpm to 600 rpm to obtain a master batch;

[0058] S4: Introduce the masterbatch obtained in step S3 into a heat-preserving internal mixer, where the internal mixing temperature in the heat-preserving internal mixer is 200°C-250°C, and the internal mixing is 20-50 minutes;

[0059] S5: take out the master batch after banburying, after cooling, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com