Super-early-strength high-strength concrete and preparation method thereof

A high-strength concrete and slow-setting technology, applied in the field of building materials, can solve problems such as low strength, long hardening time, and weak bonding between new and old concrete interfaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

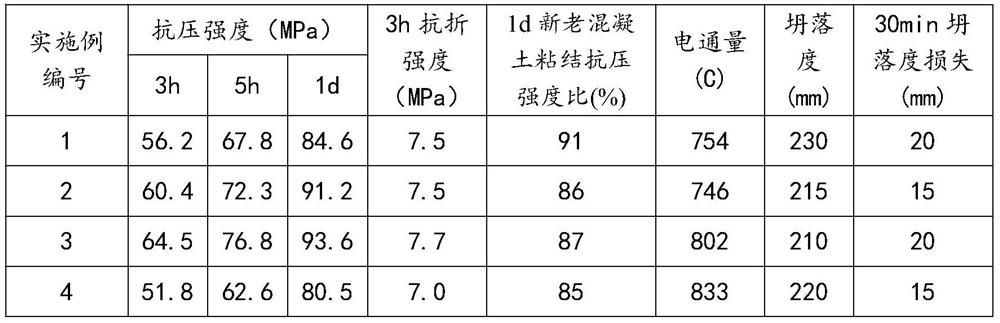

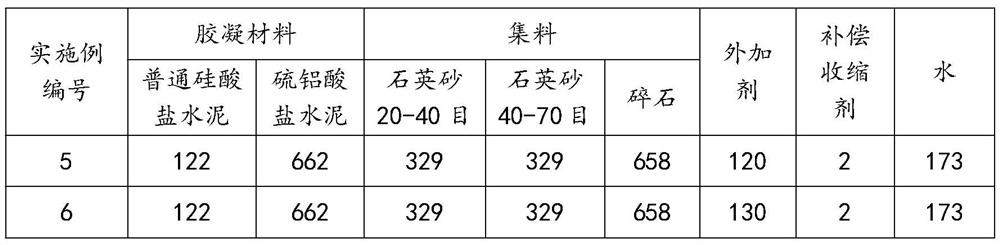

Embodiment 1-4

[0039] In Example 1-4, the admixture is 126 parts, and each admixture includes 0.25 part of early strength component, 0.12 part of retarding component, 0.08 part of viscosity increasing component and 0.45 part of water reducing component, and adopts solid compounding Component admixtures. 2 parts of shrinkage compensation agent, 329 parts of 20-40 mesh quartz sand, 329 parts of 40-70 mesh quartz sand, 658 parts of gravel, 0.22 weight ratio of water to cementitious material, and 173 parts of water.

[0040] Embodiment 1~4 prepares the method for ultra-early-strength high-strength concrete, comprises the following steps:

[0041] S1: Stir the coarse aggregate, fine aggregate and cementitious material evenly;

[0042] S2: Add admixture and shrinkage compensating agent and stir, stir evenly;

[0043] S3: Add water and stir, and stir slowly for 30s until a slurry appears;

[0044] S4: Continue to stir quickly and evenly to obtain ultra-early-strength and high-strength concrete. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com