Patents

Literature

35results about How to "No shrinkage cracks" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

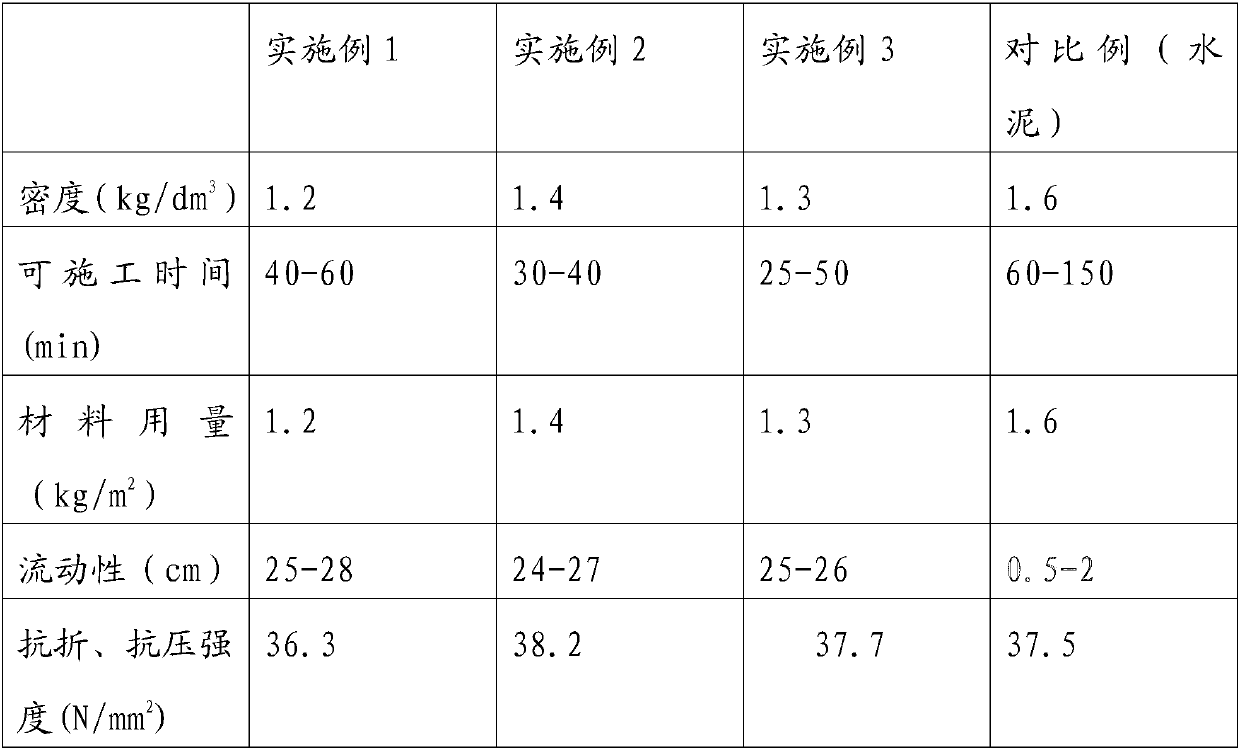

Polymer cement based self-levelling materials and preparation method thereof

The invention relates to a polymeric cement gravity flow leveling material prepared from silicate cement, polymer emulsion powder, high-alumina cement, mineral blending materials, high efficiency water reducing agent, defoaming agent, and quartz sand and with right weight ratio through finite process, material possesses good mobility, stability, high early stage folding and compression resistant strength, thus can be widely applied in ground surface leveling and mending of old ground surface, sand streak ground surface and ground surface with less qualified construction.

Owner:SHANGHAI JIANWEI CULTURAL HERITAGE CONSERVATION TECH CO LTD

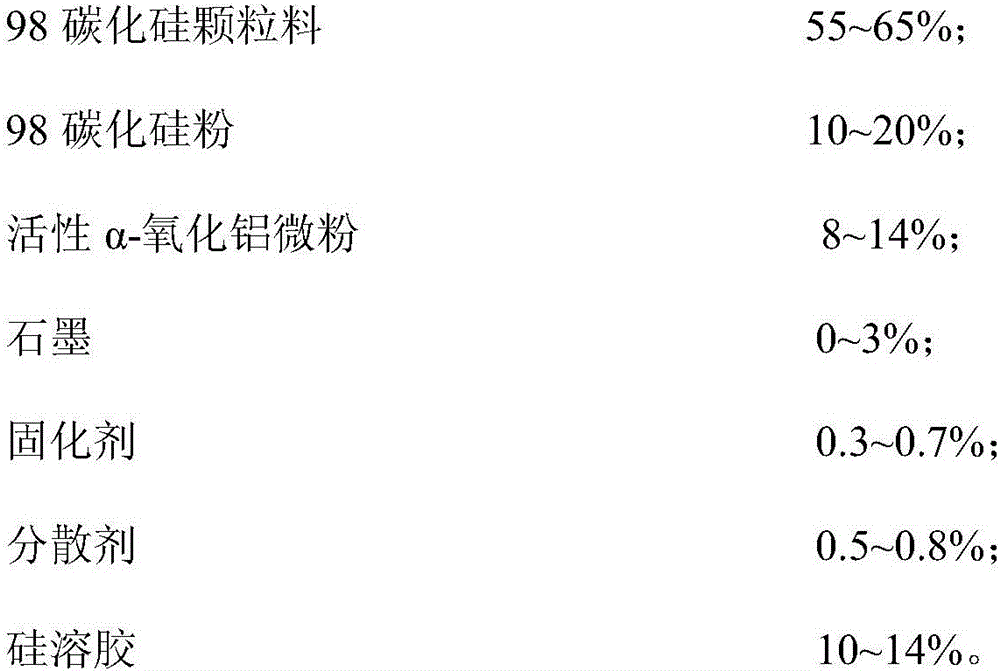

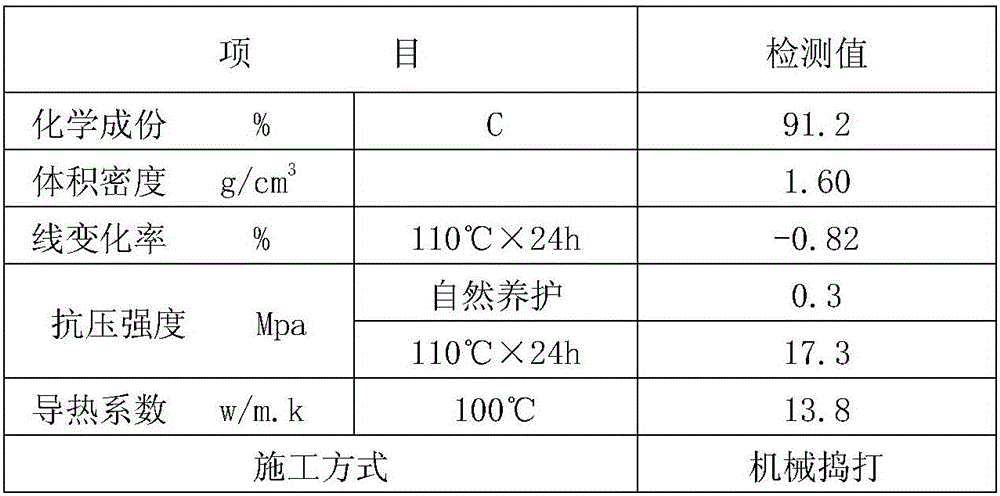

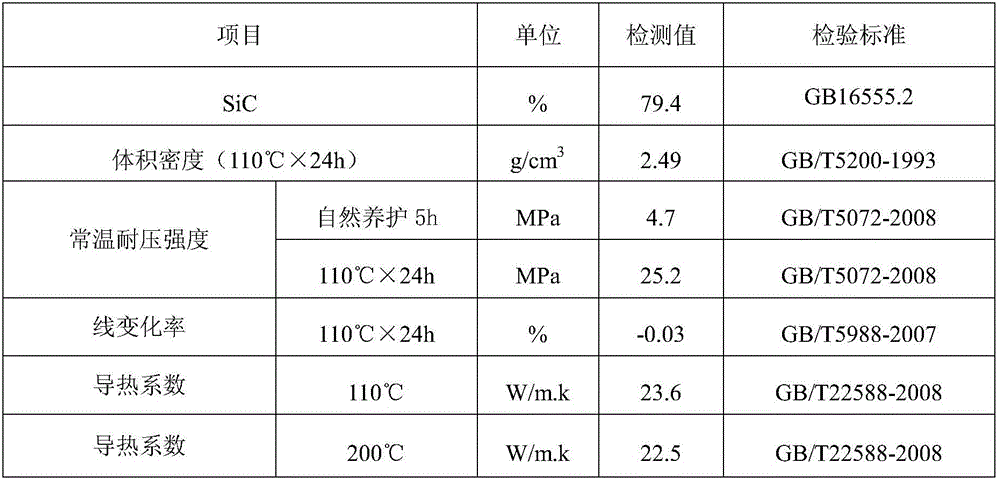

High thermal conductivity silicon carbide grouting material combined with sol used for bottom leveling of blast furnace

This invention belongs to refractory material field. It is concerned with a kind of high thermal conductivity silicon carbide grouting material combined with sol used for bottom leveling of blast furnace. The raw material component proportion of high thermal conductivity silicon carbide grouting material combined with sol is that 55-65% of 98 silicon carbide particle,10-20% of 98 silicon carbide powder, active a The invention discloses a novel coating material to be applied at the bottom of blast furnace with ingredients as follow: 8 to 14 percent of alumina powder, 0 to 3 percent of graphite, , 0.3 to 0.7 percent of curing agent, 0.5 to 0.8 percent of dispersing agent, and 10 to 14 percent of silica solution. The high-thermal conductivity silicon carbide pouring material described in this invention is easy to be constructed with short construction period, high thermal conductivity, high flatness, and long volume stability. Also the novel coating material is difficult to deform with strong anti-corrosion ability and without environment pollution, which is a novel coating material to be applied at the bottom of blast furnace.

Owner:中冶武汉冶金建筑研究院有限公司

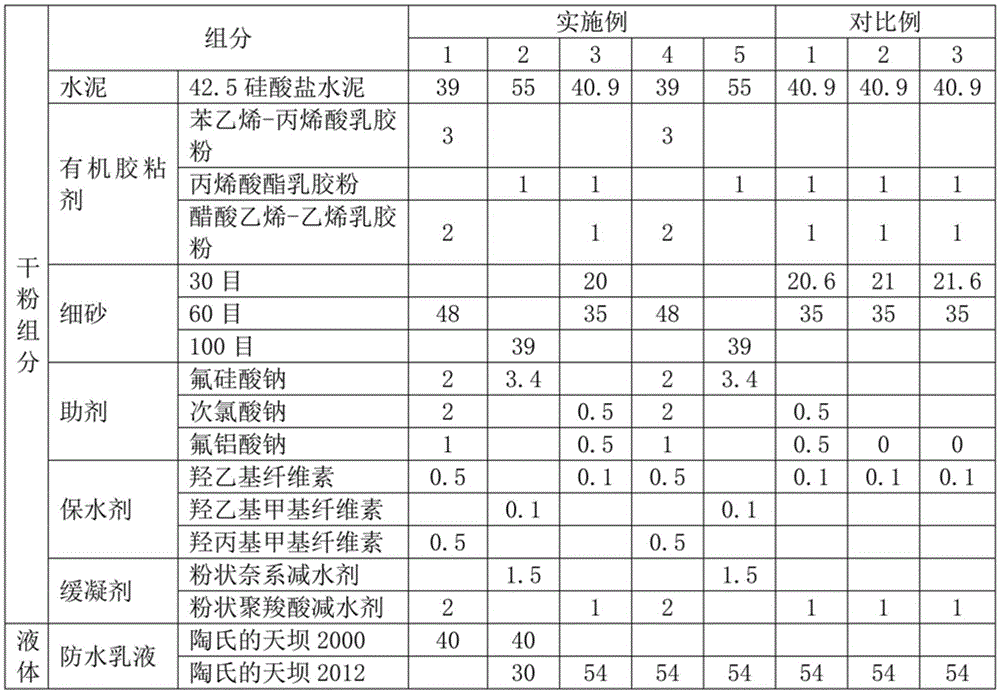

Multifunctional bicomponent ceramic tile gum composition and use method thereof

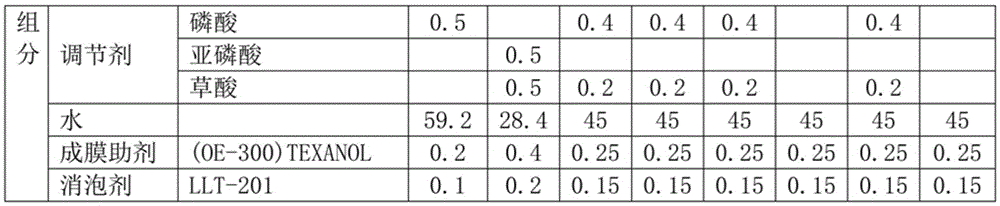

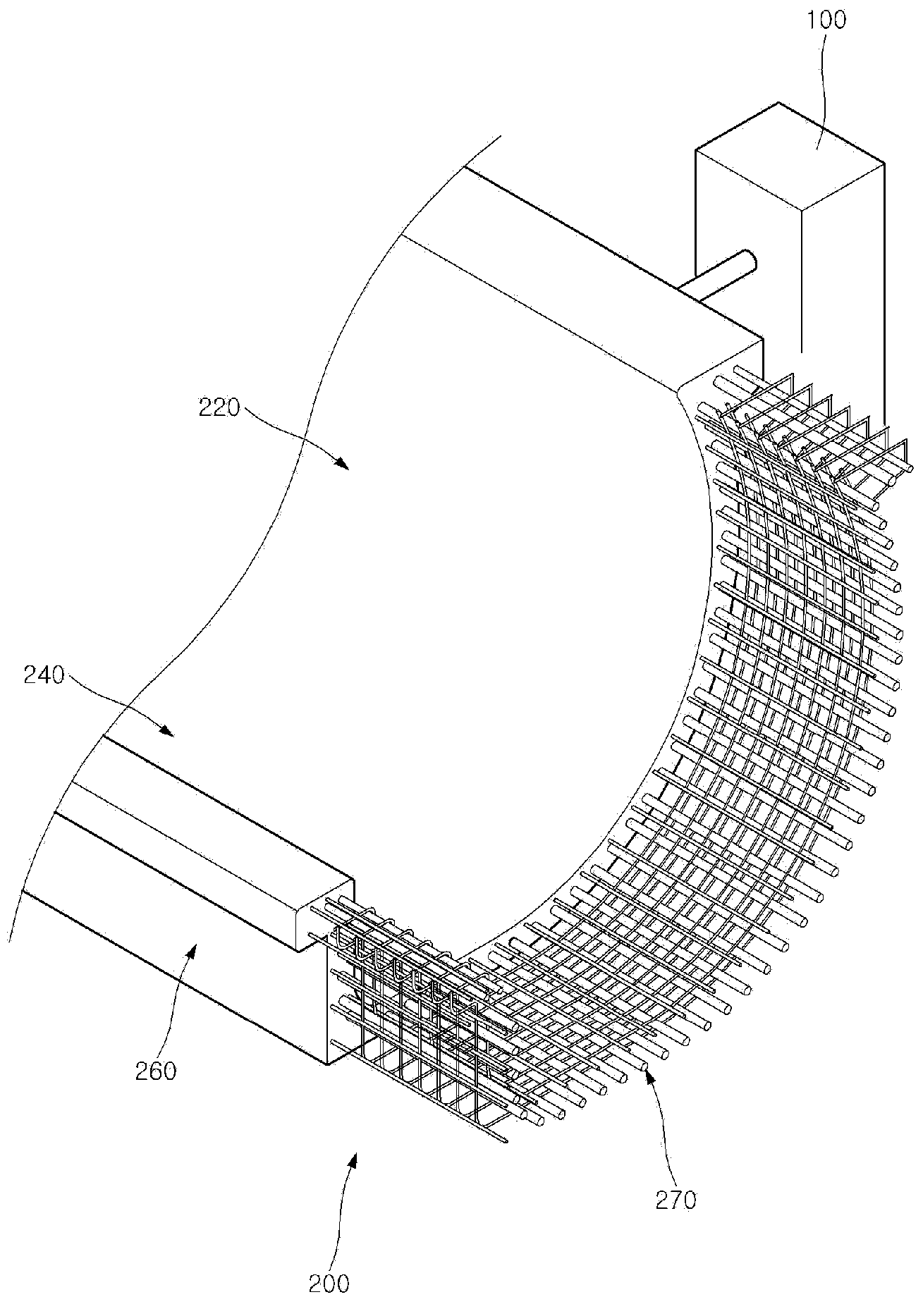

The invention discloses a multifunctional bicomponent ceramic tile gum composition and a use method thereof. The composition consists of a dry powder component and a liquid component, wherein the dry powder component comprises the following components in percentage by weight based on the total weight of the dry powder: 39-55% of cement, 1-5% of an organic adhesive, 39-55% of fine sand, 1-5% of an auxiliary agent, 0.1-1% of a water retention agent and 1-2% of an inhibiting agent; and the liquid component comprises the following components in percentage by weight based on the total weight of the liquid component: 40-70% of waterproof emulsion, 0.5-1% of a regulator, 28.4-59.2% of water, 0.2-0.4% of a coalescing agent and 0.1-0.2% of a defoaming agent. The composition disclosed by the invention integrates functions of conventional ceramic tile gum and ceramic tile adhesive, and the dry powder component in the composition can be used as a conventional ceramic tile adhesive after water is added and stirred, so that the ceramic tile adhesive is not needed; and the problems of probable maladjustment, hollowing, flaking, shedding and the like caused by mixed use of different types of ceramic tile gums and ceramic tile adhesives on the market at present are solved.

Owner:上海贝恒人居建设集团南通有限公司

Super early strong strength self-compaction material for engineering first-aid repair

The invention provides a super early-strength self-compacting material used for engineering emergency repair. The material comprises the following components and contents with parts by weight: 25-60 parts of cement, 50-80 parts of sand, 60-150 parts of stone, 0.25-2.5 parts of a water reducing agent and 0.1-1.2 parts of a coagulant. The beneficial effects of the invention are that (1) one-hour compressive strength of patching materials is improved to more than 30MPa, after one-hour construction, the traffic can be resumed or the production can be recovered, and the like; (2) by optimizing the proportion, the contraction cracks of the patching materials are not produced when in construction at a large scale; (3) the patching materials can be applied to emergency construction under the condition of negative temperature.

Owner:BEIJING NEW VISION BUILDING CONSTR TECH

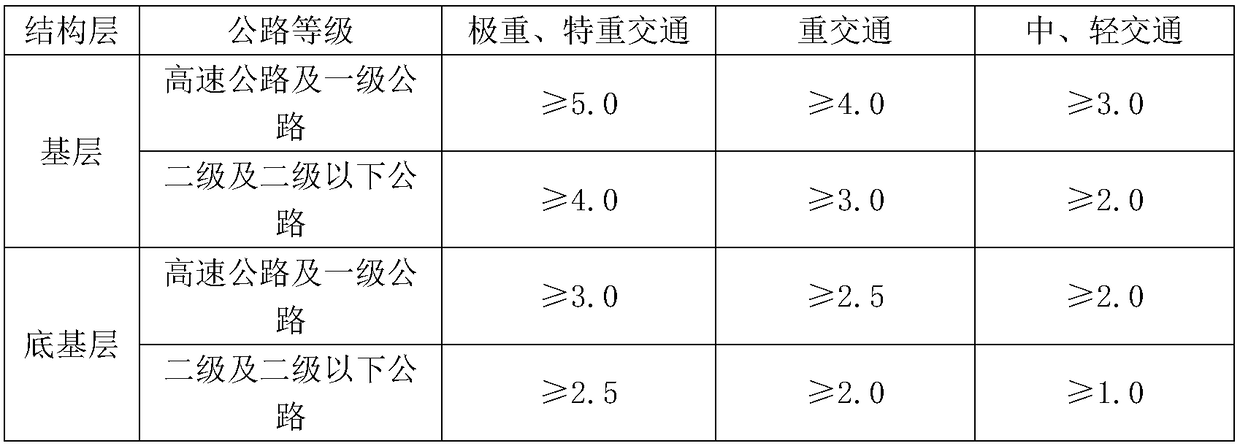

Paving method for pavement base of road

ActiveCN108570897AReduce fuel consumptionReduced mechanical propertiesRoadwaysRoad surfaceUltimate tensile strength

The invention provides a paving method for a pavement base of a road. According to the invention, the special curing agent PCSB is blended with waste powder recovered from an asphalt concrete mixing station and coarse and fine aggregates according to a certain ratio, and then water is added for blending before paving of the pavement base. Since the PCSB curing agent is used for consolidating a waste asphalt powder material in paving of the pavement base, the pavement base can reach strength of 6.0 MPa or more and is free of cracking; a construction process is simple and manual kerf sawing is not needed; and the pavement base is allowed to have high strength, good integrity and good stability, and engineering cost for the road is reduced at the same time.

Owner:武汉江夏路桥工程总公司

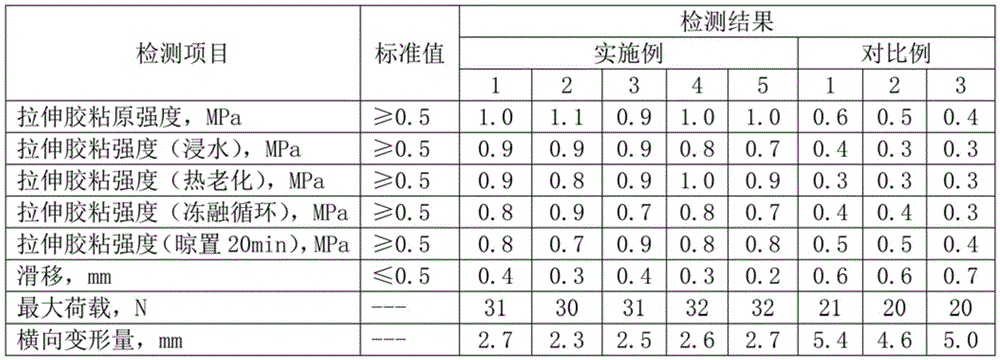

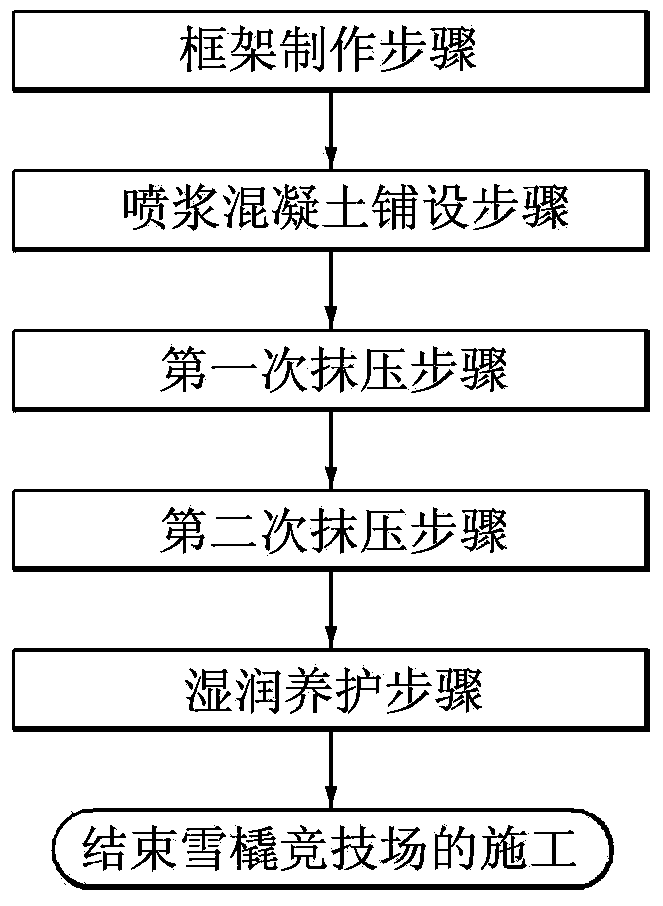

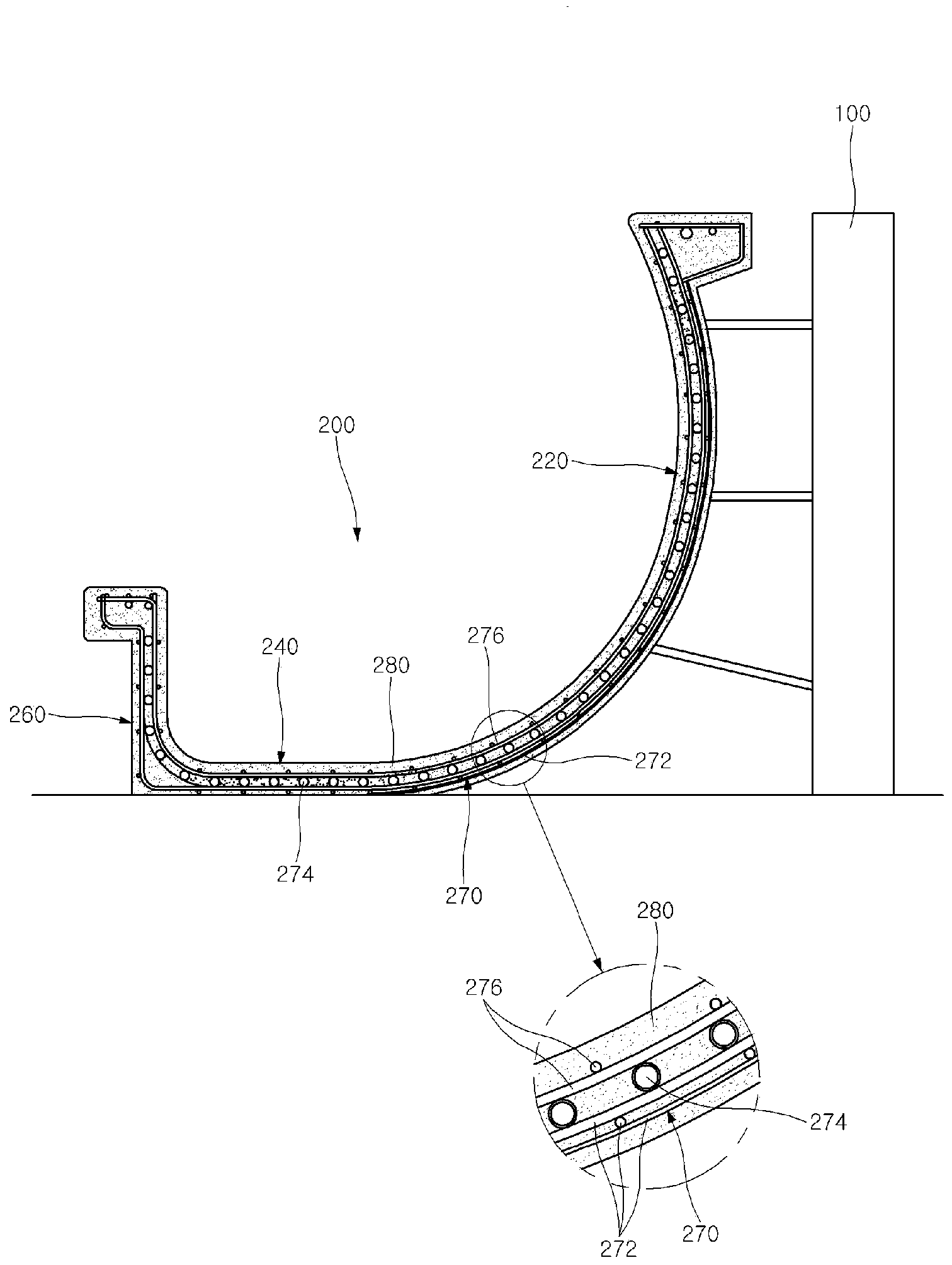

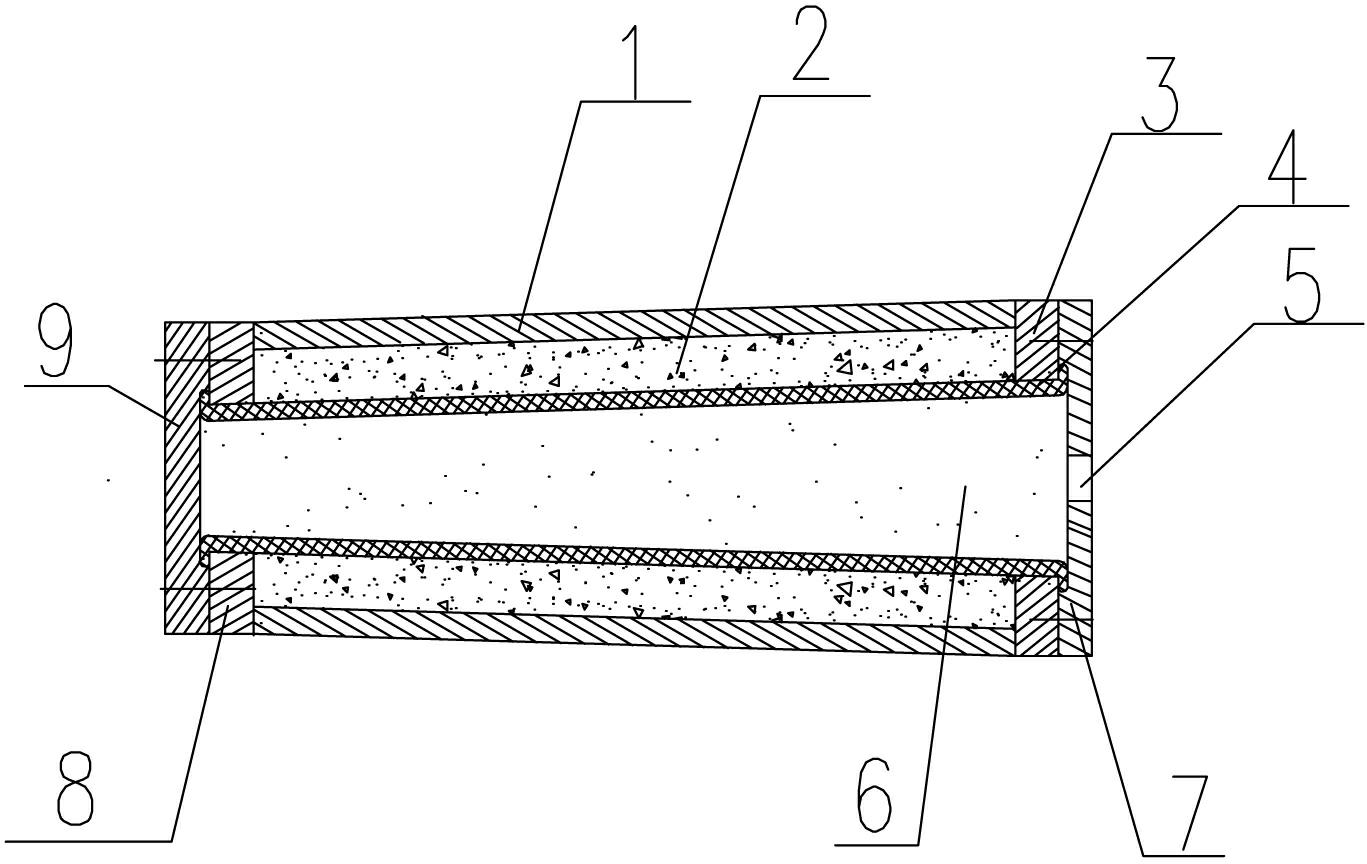

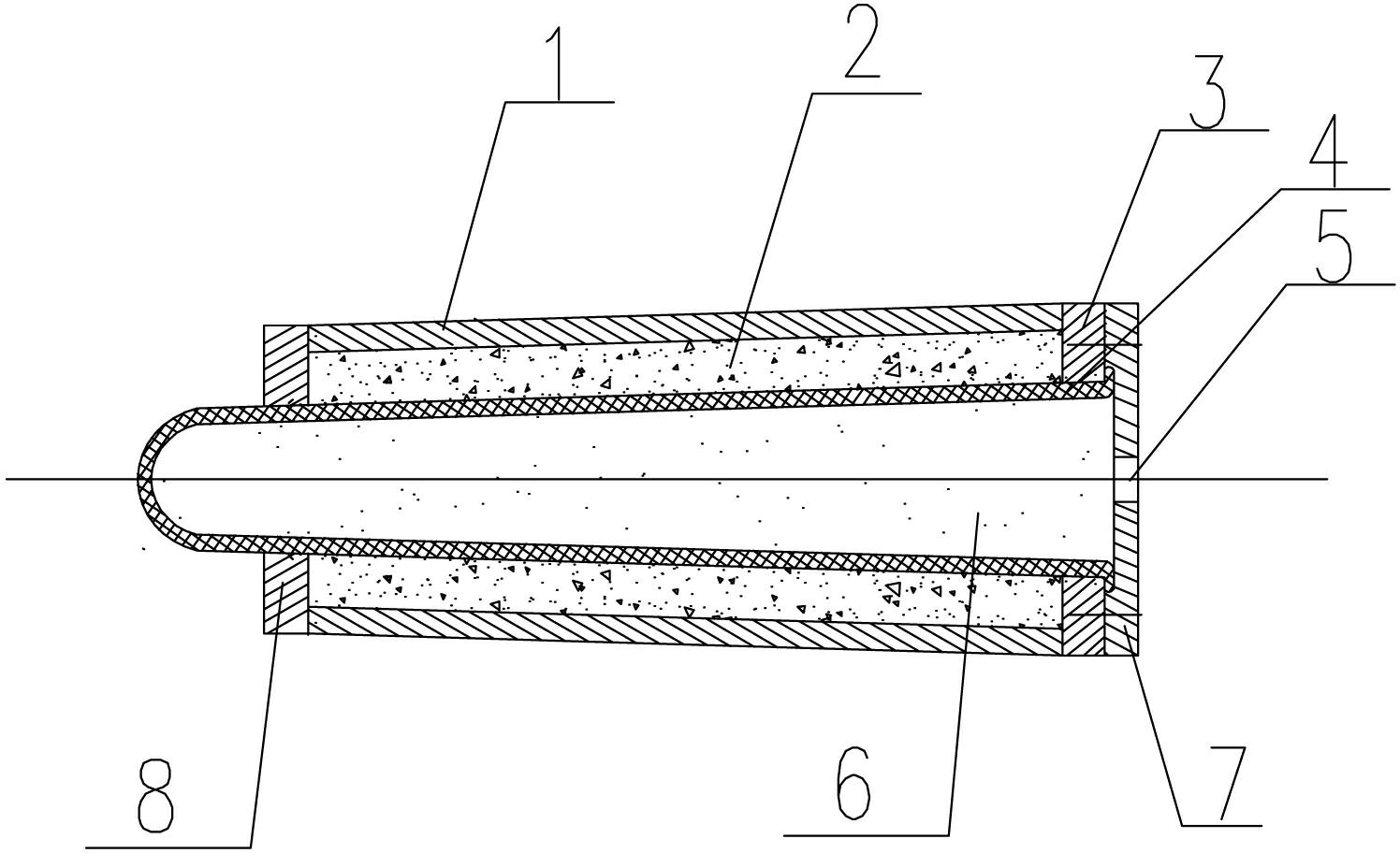

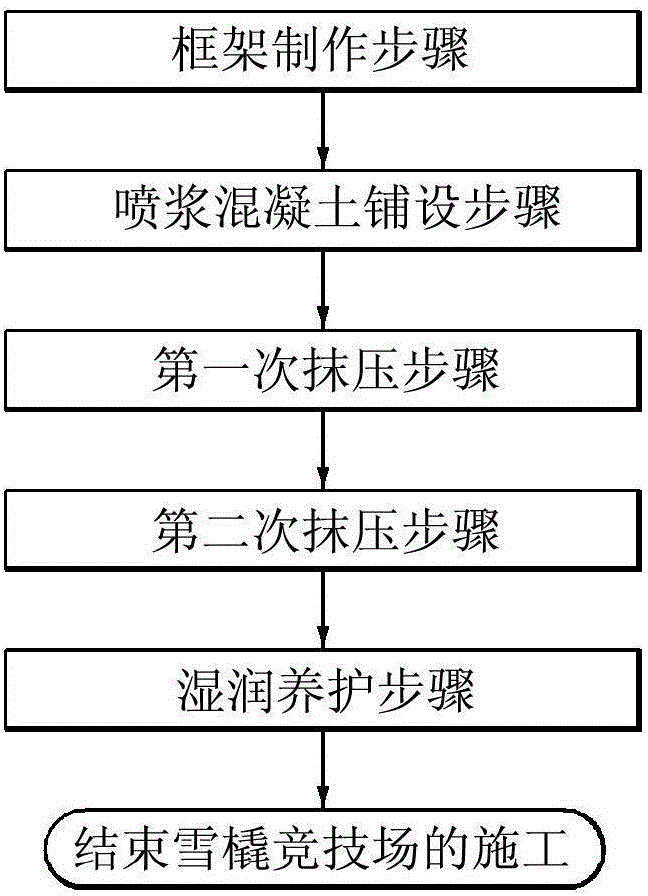

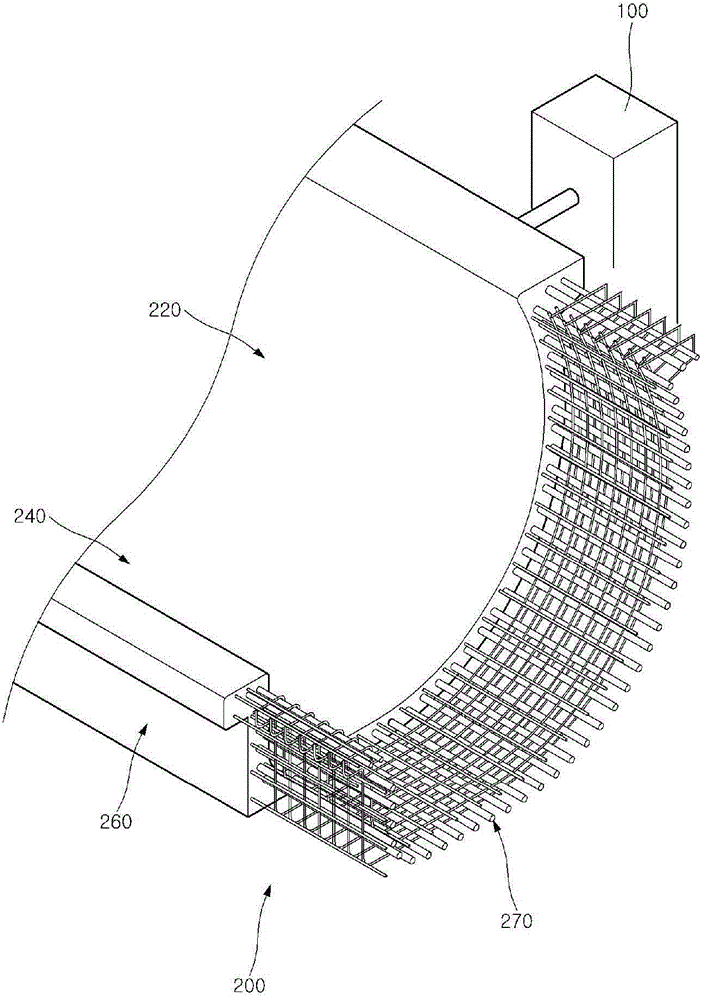

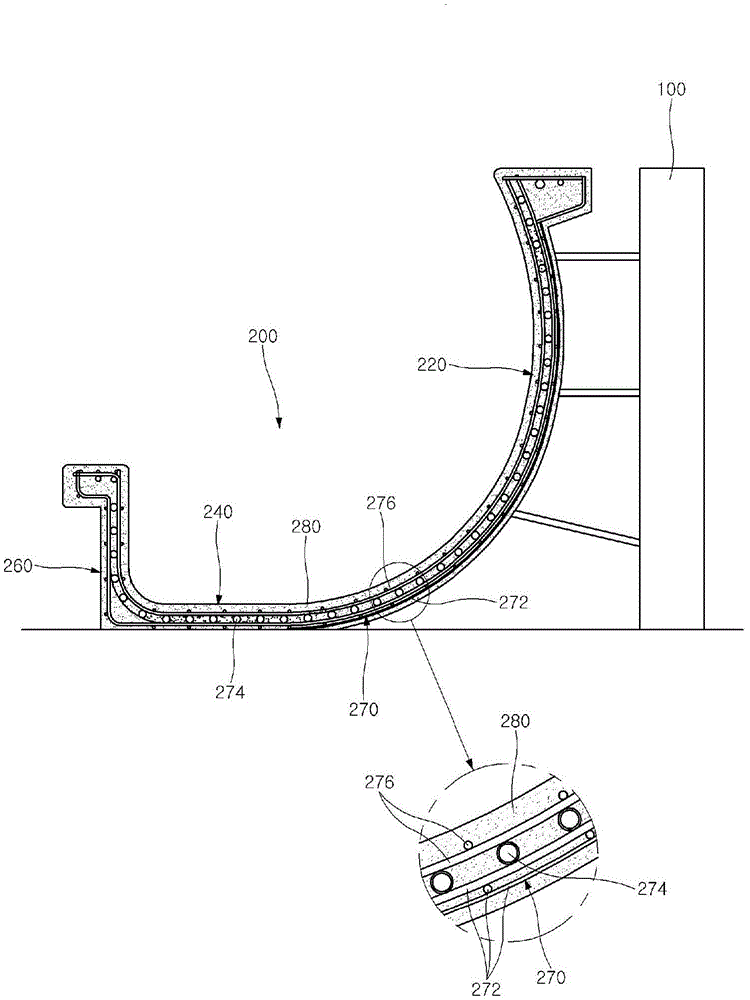

Method for constructing a bobsleigh course using a high-performance wet-type shotcrete composition

InactiveCN103906552AGood construction performanceHigh compressive strengthSki bindingsTunnel liningRough surfaceShotcrete

The present invention relates to a method for constructing a bobsleigh course using a high-performance wet-type shotcrete composition, and more particularly, to a method of constructing a bobsleigh course that uses a high-performance wet-type shotcrete composition which includes silica fumes and AE material, and which has increased pumpability prior to being deposited due to the presence of a superabundant amount of air, and increased shootability after being deposited since the amount of air present is decreased, thus imparting high constructability, high strength, and high durability to the composition. To this end, the method comprises: a framework-forming step of fixing a wire-mesh formwork, positioning a cooling pipe, strengthening adherence and holding strength, and installing a curvature-maintaining pipe; a shotcrete-laying step of laying the shotcrete composition; a first surface-finishing step of setting a curved surface and performing finishing using plastering; a second surface-finishing step of performing a rough surface finishing; and a wet curing step of performing wet curing.

Owner:KNU IND COOPERATION FOUND +1

Gypsum-based self-leveling mortar and preparation method thereof

The invention relates to gypsum-based self-leveling mortar and a preparation method thereof. The gypsum-based self-leveling mortar comprises, by weight, 40-60 parts of anhydrite, 4-6 parts of cement,40-60 parts of quartz sand, 0.06-0.10 part of retarder, 0.06-0.08 part of water reducing agent, 0.08-0.10 part of water-retaining agent, 0.05-0.08 part of defoaming agent and 2-3 parts of redispersible latex powder. The preparation method includes: weighing the components according to the weight, and evenly mixing to obtain the gypsum-based self-leveling mortar. The gypsum-based self-leveling mortar is good in thermal insulation and sound insulation performance, capable of effectively increasing construction speed during use, capable of saving a large amount of manpower and capable of increasing the flatness of leveling operation.

Owner:王明忠

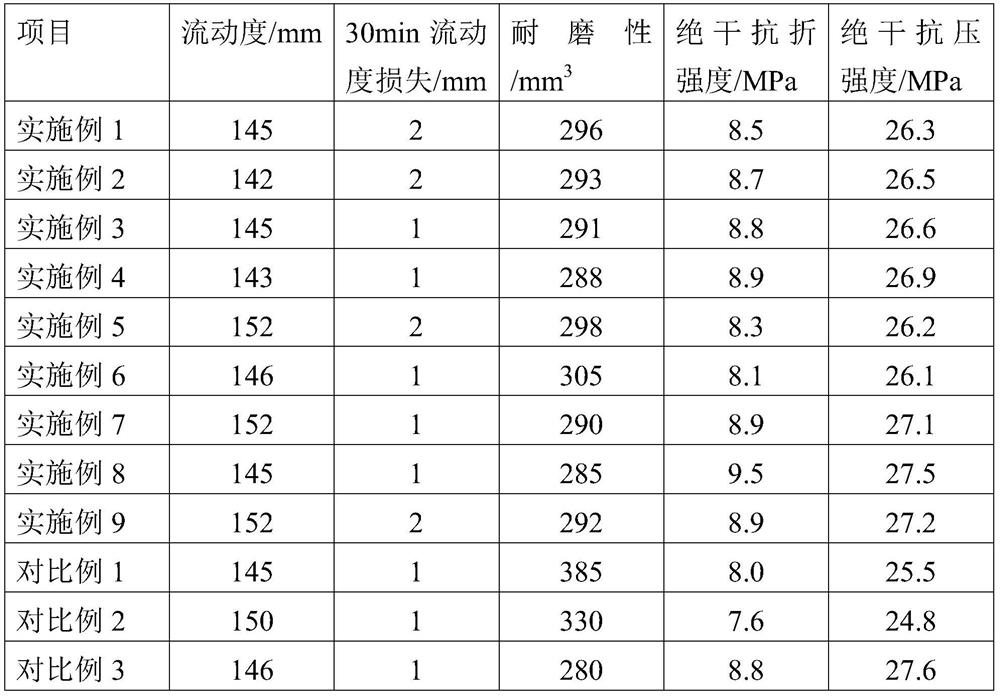

High-wear-resistance gypsum-based self-leveling mortar and preparation method thereof

The invention provides high-wear-resistance gypsum-based self-leveling mortar and a preparation method thereof. The high-wear-resistance gypsum-based self-leveling mortar is prepared from the following raw materials in parts by weight: 100 parts of desulfurized building gypsum, 20-25 parts of a modified reinforcing material, 80-100 parts of aggregate, 2-3 parts of rubber powder, 0.3-0.4 part of a retarder, 0.3-0.4 part of a water reducing agent, 0.2-0.3 part of a defoaming agent, 0.1-0.2 part of a water-retaining agent and 35-50 parts of water. The preparation method specifically comprises the following steps: grinding the aggregate and 50 parts of desulfurized building gypsum into a grinding material; premixing rubber powder, a retarder, a water reducing agent, a defoaming agent and a water-retaining agent to obtain a mixture; and mixing a modified reinforcing material and 50 parts of desulfurized building gypsum with the grinding material and the mixture, and then adding water and stirring to obtain the high-wear-resistance gypsum-based self-leveling mortar. The gypsum-based self-leveling mortar disclosed by the invention has the advantages of good flowability, relatively high early and later strength, no shrinkage crack caused by micro-expansion, strong adhesion with a substrate and the like, and is good in wear resistance.

Owner:河南建筑材料研究设计院有限责任公司 +2

Pavement base structure of road

The objective of the invention is to provide a pavement base structure of a road. The pavement base structure comprises a base and a subbase. The pavement base structure is characterized in that the subbase comprises, by mass, 2 to 7.5% of a PCSB curing agent, 15 to 28% of waste asphalt powder, 35 to 50% of fine aggregate and 25 to 40% of coarse aggregate (summing to 100%); and the base comprises,by mass, 2.5 to 8% of the PCSB curing agent, 18 to 30% of waste asphalt powder, 35 to 50% of fine aggregate and 25 to 40% of coarse aggregate (summing to 100%). The pavement base structure can reduceshrinkage cracks, improve the quality of a pavement base and lower engineering cost for the road.

Owner:武汉江夏路桥工程总公司

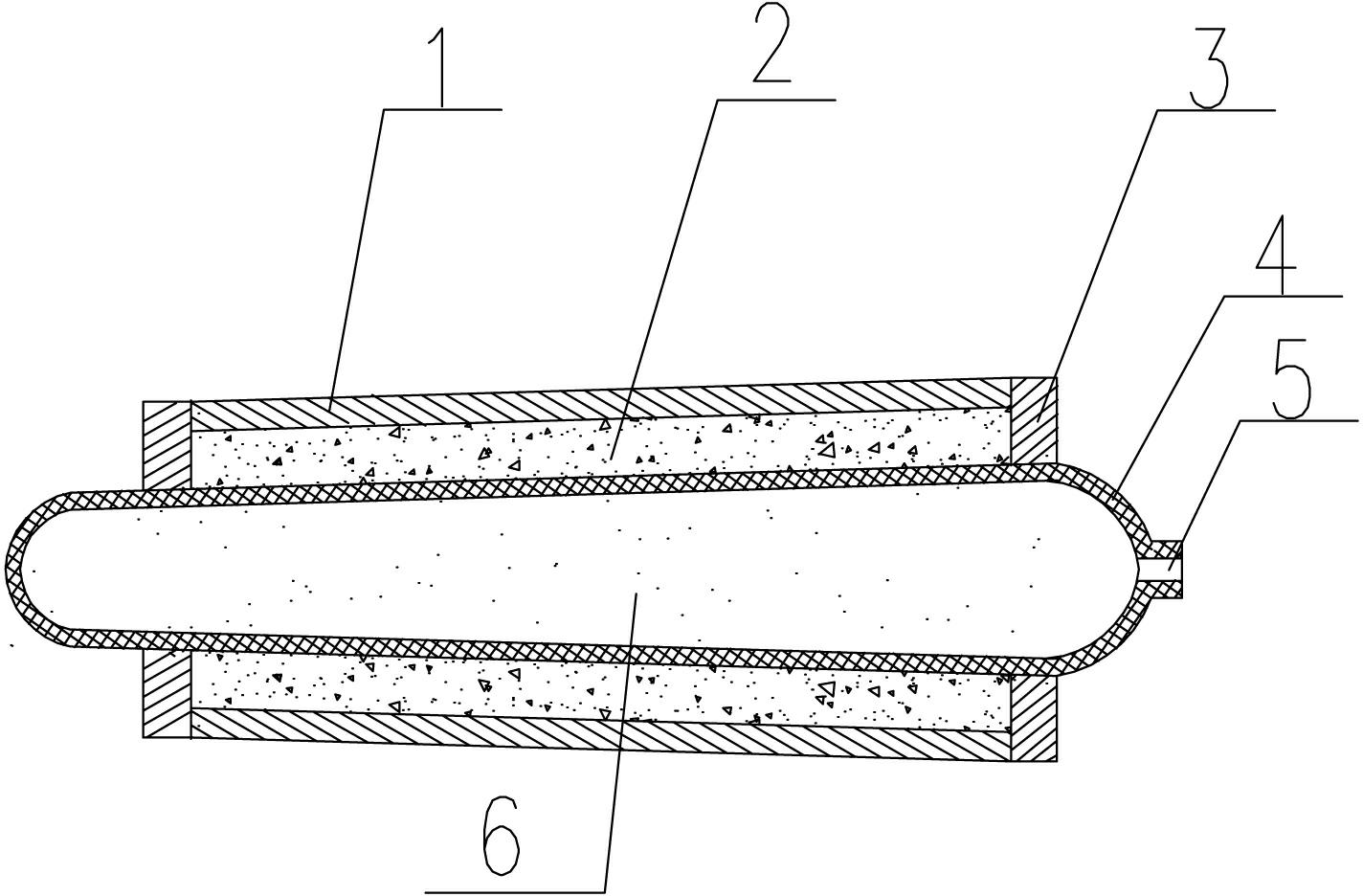

Resin concrete sleeper

The invention relates to the field of sleepers, and particularly discloses a resin concrete sleeper. The resin concrete sleeper comprises a sleeper body, reinforcing steel bars are arranged in the sleeper body, the sleeper body is formed by solidifying a resin concrete material, and the resin concrete material is formed by mixing the following raw materials in parts by weight: 15-25 parts of epoxy resin, 10-25 parts of powder, 35-50 parts of aggregate, 3-6 parts of a reactive diluent, 3-5 parts of a flexibilizer, 5-8 parts of other additives and 5-8 parts of fibers. According to the resin concrete sleeper, the epoxy resin is used in the concrete to replace cement to serve as the cementing material, the epoxy resin reacts with the curing agent to achieve gelatinization, solidification shrinkage is small, shrinkage cracks are few, the mechanical property is good, and compared with common concrete, the resin concrete sleeper has the advantages of being high in strength and low in density, can achieve lighter weight and is convenient to construct; meanwhile, the elasticity of the epoxy resin sleeper is good, rail vibration can be effectively buffered and conducted, pulverization of ballast is reduced, and sinking of the sleeper is reduced.

Owner:威海瑞合铁路轨枕有限公司

Thin-walled centrifugal concrete pole manufacture method

ActiveCN102601860AGuaranteed StrengthNo shrinkage cracksCeramic shaping apparatusInjection portUltimate tensile strength

The invention relates to a thin-walled centrifugal concrete pole manufacture method, which includes the steps: manufacturing a reinforcing rib framework, placing the reinforcing rib framework and stirred concrete into a centrifugal mould, rotating a centrifuge so that the concrete is uniformly distributed on the inner wall of the centrifugal mould to form a thin-walled centrifugal concrete pole wet green, taking the centrifugal mould down from the centrifuge, and solidifying the thin-walled centrifugal concrete pole wet green prior to steam curing and cooling demoulding. The method is characterized in that solidification of the thin-walled centrifugal concrete pole wet green is realized by leading a soft pressurizing membrane longer than the thin-walled centrifugal concrete pole wet green, made of plastics or rubber and provided with a media injection port into a central hollow cavity of the concrete pole wet green, adding pressurizing media so that the soft pressurizing membrane forms a closed cavity, keeping pressure of the pressurizing media until the concrete is solidified, emptying the pressurizing media, and taking the soft pressurizing membrane out prior to steam curing and cooling demoulding. The thin-walled centrifugal concrete pole manufacture method effectively avoids possibility of micro-cracks generated due to contraction distortion of the concrete for manufacturing a thin-walled concrete pole during solidification, so that the integral strength of the thin-walled concrete pole is improved.

Owner:元工能源科技集团有限公司

Highway pavement base layer free of crack and preparation method thereof

ActiveCN108708244AReduce manufacturing costImprove bearing capacityIn situ pavingsMixed materialsRoad surface

The invention discloses a highway pavement base layer free of a crack and a preparation method thereof to solve deficiency in the prior art. The highway pavement base layer is made of stirring cement,fine aggregate, coarse aggregate, a coagulation alleviating and water reducing agent and water. The highway pavement base layer comprises, by mass, 5-6% of the cement, 60-69% of the fine aggregate, 22.2-29% of the coarse aggregate, 0.6-3% of the cement amount of the coagulation alleviating and water reducing agent, and the ratio of water to ash is 0.65-0.7. The preparation method comprises the following steps that step 1, the mixed materials are stirred; step 2, paving and additional watering are carried out; step 3, grinding and pressing are carried out; and step 4, maintaining is carried out. The deficiency of semi-rigid base layer air shrinking and cracking is overcome, and advantages of a semi-rigid base layer is kept; pavement bearing capacity is high, shrinkage and cracking do not occur; and highway manufacturing cost is reduced and the service life is prolonged.

Owner:杜宇

925 silver alloy with yellow appearance and high hardness and process thereof

The invention discloses 925 silver alloy with a yellow appearance and high hardness and a process thereof. The 925 silver alloy is prepared from the following components in percentage by weight of 0.2-0.3 wt% of P, 0.5-0.6 wt% of Li, 1.4-1.8 wt% of Zn, 0.2-0.4 wt% of Re, 1.0-1.5 wt% of Co, 0.3-0.5 wt% of W, 92.0-93.0 wt% of Ag and the rest of copper. The 925 silver alloy for jewelries in China hasthe yellow appearance and excellent characteristics of high hardness and wear resistance. The implementation and industrialization of the 925 silver alloy can effectively promote the update of jewelry industry products in China and meet the need of industry upgrade, and the industry problem can be solved and meanwhile fruitful economic results and social benefits can be achieved.

Owner:GUANGZHOU YUZHI TECH CO LTD

Silver alloy with resistance to hydrogen sulfide corrosion discoloration and red appearance and machining process thereof

InactiveCN108866377ALow solidification shrinkageExcellent mechanical and processing propertiesCorrosionMachining process

The invention discloses a silver alloy with resistance to hydrogen sulfide corrosion discoloration and red appearance and a machining process thereof. The silver alloy is prepared from the following components in percentage by weight: 0.1-0.2wt% of B, 0.6-0.8wt% of Sc, 1.2-1.4wt% of Ti, 0.2-0.4wt% of V, 12.0-15.0wt% of In, 0.8-1.2wt% of Ta, 30.0-32.0wt% of Cu and the balance of silver. Through thesilver alloy, a solution of material science is provided for the silver alloy applied to jewelries in China and provided with red appearance; the silver alloy has excellent resistance to hydrogen sulfide corrosion blackening; implementation and industrialization of the silver alloy can effectively solve the current situation that product types in the field of colored silver are restricted and insufficient; the silver alloy will certainly achieve fruitful economic result and social benefit in the future.

Owner:GUANGZHOU YUZHI TECH CO LTD

Casting mold repair method

InactiveCN104117634BHigh strengthImprove wear resistanceFoundry mouldsFoundry coresSurface layerAlcohol

The invention provides a method for repairing a casting mold, the steps of which are: 1) cleaning the parts to be repaired of the wooden, aluminum or steel casting molds to be repaired, and wiping them with alcohol; Choose a specific repair method for the size of the part: when the largest size of the part to be repaired is not less than 10mm, first pre-fill with the back layer repair material, and then coat the surface layer repair material after the back layer material is hardened; otherwise, directly Coating and repairing with surface repair materials; 3) Repairing the repairing layer of the casting mold after coating and repairing with manual electric grinding and polishing equipment, so that the size of the repairing layer meets the size requirements of the casting mold, and the surface of the repairing layer Grinding smooth and flat until the roughness is not less than 0.8Ra level, that is, the repair of the casting mold is completed. The invention has the advantages of simple process, low repair cost and short repair period, and is suitable for repair requirements of casting molds made of various materials such as wood, aluminum or steel.

Owner:SHANDONG UNIV OF TECH

Blue gloss fading-resistant 958 silver alloy for jewelry and process of blue gloss fading-resistant 958 silver alloy

InactiveCN108796289APromote sheddingNo discoloration occurredSolid state diffusion coatingSocial benefitsAlloy

The invention discloses a blue gloss fading-resistant 958 silver alloy for jewelry and a process of the blue gloss fading-resistant 958 silver alloy. The alloy comprises, by weight, 0.2-0.3% of P, 0.5-0.6% of Sr, 0.6-0.8% of Mo, 0.2-0.4% of Ir, 1.0-1.5% of Co, 0.3-0.5% of In, 95.0-96.0% of Ag, and the balance copper. A new material with blue appearance is provided for the 958 silver alloy for thejewelry in China, and the material has excellent fading resistance. The implementation and industrialization of the material can effectively promote the demands of product updating and industry upgrading in the jewelry industry of China, and rich economic gains and social benefits are obtained when the industry problems are solved.

Owner:GUANGZHOU YUZHI TECH CO LTD

Yellow silver alloy for jewelry with hydrogen sulfide corrosion resistance and tarnish resistance and machining technology thereof

The invention discloses a yellow silver alloy for jewelry with hydrogen sulfide corrosion resistance and tarnish resistance and a machining technology thereof. The alloy comprises the following components of, by weight, 0.1-0.2% of C, 1.0-1.2% of Y, 1.5-1.8% of Ti, 0.2-0.5% of Hf, 10.0-12.0% of Zn, 0.8-1.2% of Mo, 15.0-15.4% of Cu, and the balance silver. The material provides a solution of material science for the silver alloy with the yellow impression for the jewelry in China, and the product has excellent characteristics of the hydrogen sulfide corrosion resistance and blackening resistance; the implementation and industrialization of the material can effectively solve the problem of insufficient variety of products and the development restricting of the silver in the field of color silver, and a huge economic result and a social benefit can be obtained in the future.

Owner:GUANGZHOU YUZHI TECH CO LTD

Yellow 958 silver alloy with high hardness and wear-resisting performance and process of yellow 958 silver alloy

The invention discloses a yellow 958 silver alloy with high hardness and wear-resisting performance and a process of the yellow 958 silver alloy. Components of the alloy comprise, by weight percent, 0.4%-0.5% of Be, 0.6%-0.8% of Sr, 0.2%-0.4% of Ta, 0.3%-0.5% of W, 1.4%-1.6% of Zn, 0.5%-0.8% of Ge, 95.0%-96.0% of Ag and the balance copper. A new material with the yellow appearance is provided forthe 958 silver alloy for domestic jewelry, and the material has the excellent wear-resisting character. By means of implementation and industrialization of the material, the requirements of product updating and industry upgrading of the domestic jewelry industry can be effectively pushed, the industry problems are solved, and meanwhile plenteous economic gains and social benefits can be obtained.

Owner:GUANGZHOU YUZHI TECH CO LTD

Imitation-gold alloy with pure gold luster for figure of Buddha in marine environment

The invention discloses a imitation-gold alloy with pure gold luster for a figure of Buddha in a marine environment. The imitation-gold alloy comprises the components of, by weight, 0.01-0.02% of B, 3.0-4.0% of Mg, 5.0-8.0% of Al, 2.0-3.0% of Fe, 2.0-3.0% of Cr, 2.0-3.0% of Sb, 0.5-0.8% Mn and the balance Cu. The imitation-gold alloy provides a cheap and effective solution for the imitation-gold alloy of a large statue in the coastal region of China, not only reduces production costs, but also effectively solves problems which bind the field. Acquiring of the fruitful economic results and social benefits can be predicted by applying and industrializing the imitation-gold alloy.

Owner:GUANGZHOU YUZHI TECH CO LTD

Cement wood-wool acoustic board and preparation method thereof

The invention relates to a cement wood-wool acoustic board. The cement wood-wool acoustic board comprises the following components in parts by mass: 100 parts of magnesia, 60-100 parts of water, 30-50 parts of magnesium chloride, 50-80 parts of wood-wool, 20-70 parts of ferrous sulfate, 1-25 parts of a reinforcing agent, 1-10 parts of a heat enhancer, 5-8 parts of a filling agent, 0.1-5 parts of titanium pigment and 1-10 parts of a foaming agent. The cement wood-wool acoustic board is excellent in water resistance, corrosion-free and acid-alkali-resistant, cannot generate shrinkage cracks, has a good heat preservation effect, is resistant to ultraviolet irradiation, and cannot deform easily after moisture absorption; the heat conductivity of the product is 0.1-0.15, the compressive strength is 0.2-0.4Mpa, the acoustic absorption coefficient is up to 0.5, the water absorptivity is 0.8-0.9, the density is 0.9-1.5, and the cement wood-wool acoustic board can be self-distinguished in 5 seconds, so that the cement wood-wool acoustic board can be widely used and continuously replace the existing materials.

Owner:NANJING FORESTRY UNIV

Construction method of bobsled arena using high performance wet shotcrete composition

InactiveCN103906552BGood construction performanceHigh compressive strengthSki bindingsTunnel liningShotcreteRough surface

Owner:KNU IND COOPERATION FOUND +1

Tin-based fade-resistant anti-brittle-fracture with pure gold color imitation 24K gold

The invention discloses a tin-based fade-resistant anti-brittle-fracture with pure gold color imitation 24K gold. The alloy comprises the following components of, by weight, 0.2-0. 4 wt.% of P, 1.5-1.8 wt.% of Ti, 0.6-0. 8 wt.% of Mo, 4.0-6.0 wt.% of Cu, 0.4-0.6 wt.% of Y, 2.0-4.0 wt.% of Sb, 0.1-0.3 wt.% of C, and the balance tin. The invention provides a cheap and fade-resistant tin-based alloywith the color of 24K gold for the decoration industry in China, and the situation that most of the conventional imitation gold alloys are copper-based alloys is broken through. The production cost isreduced, and the problem in the field is effectively solved. It is expected that the implementation and industrialization of the material can obtain good economic and social benefits.

Owner:GUANGZHOU YUZHI TECH CO LTD

925 silver alloy with red appearance and resistance to hydrogen sulfide corrosion and process thereof

The invention discloses a 925 silver alloy with a red appearance and resistance to hydrogen sulfide corrosion and a process thereof. The alloy comprises the compositions of, by weight, 0.1 to 0.2 wt.%of B, 0.6 to 0.8 wt.% of Li, 0.2 to 0.3 wt.% of Mo, 0.1 to 0.2 wt.% of Os, 1.0 to 1.5 wt.% of Fe, 0.2 to 0.4 wt.% of Ti, and 92.0 to 93.0 wt.% of Ag, and the balance copper. According to the 925 silver alloy with the red appearance and the resistance to hydrogen sulfide corrosion and the process thereof, a novel material with the red appearance is provided for the 925 silver alloy for jewelry ofChina, and the material has the excellent characteristic of resistance to blackening by hydrogen sulfide corrosion. The implementation and industrialization of the material can effectively meet the demands for product upgrading and industrial upgrading in the jewelry industry of China, and can achieve fruitful economic results and social benefits while solving industrial problems.

Owner:GUANGZHOU YUZHI TECH CO LTD

925 silver alloy with purple appearance and brittle failure resistance, and process thereof

The invention discloses a 925 silver alloy with the purple appearance and brittle failure resistance, and a process thereof. The 925 silver alloy comprises the components of, by weight, 0.4-0.6% of Be, 0.8-1.2% of Li, 1.5-1.6% of Al, 0.2-0.3% of Ru, 0.6-0.8% of Sc, 1.5-1.8% of In, 92.0-93.0% of Ag and the balance copper. The 925 silver alloy provides a brand-new material with the purple appearancefor 925 silver alloys for jewelry in China, and the 925 silver alloy has the excellent characteristic of brittle failure resistance. Implementation and industrialization of the 925 silver alloy can effectively promote the demands of product renewal and industry upgrading of the jewelry industry in China, and abundant economic gains and social benefits are obtained while the industry problems aresolved.

Owner:GUANGZHOU YUZHI TECH CO LTD

Polymer cement based self-levelling materials and preparation method thereof

The invention relates to a polymeric cement gravity flow leveling material prepared from silicate cement, polymer emulsion powder, high-alumina cement, mineral blending materials, high efficiency water reducing agent, defoaming agent, and quartz sand and with right weight ratio through finite process, material possesses good mobility, stability, high early stage folding and compression resistant strength, thus can be widely applied in ground surface leveling and mending of old ground surface, sand streak ground surface and ground surface with less qualified construction.

Owner:SHANGHAI JIANWEI CULTURAL HERITAGE CONSERVATION TECH CO LTD

A paving method for road pavement base

ActiveCN108570897BNo shrinkage cracksImprove water stabilityRoadwaysRoad engineeringArchitectural engineering

The invention provides a road pavement base paving method, which uses a special curing agent PCSB, mixed with waste powder recovered from asphalt concrete mixing stations, coarse and fine aggregates in a certain proportion, and mixed with water to pave the pavement base. The invention uses PCSB curing agent to consolidate asphalt waste powder materials, and paves the pavement base, which can reach a strength of more than 6.0 MPa, without cracking, simple construction technology, and no manual sawing, which ensures high strength, good integrity and stability of the pavement base Well, at the same time reduce the cost of road works.

Owner:武汉市江夏路桥工程有限公司

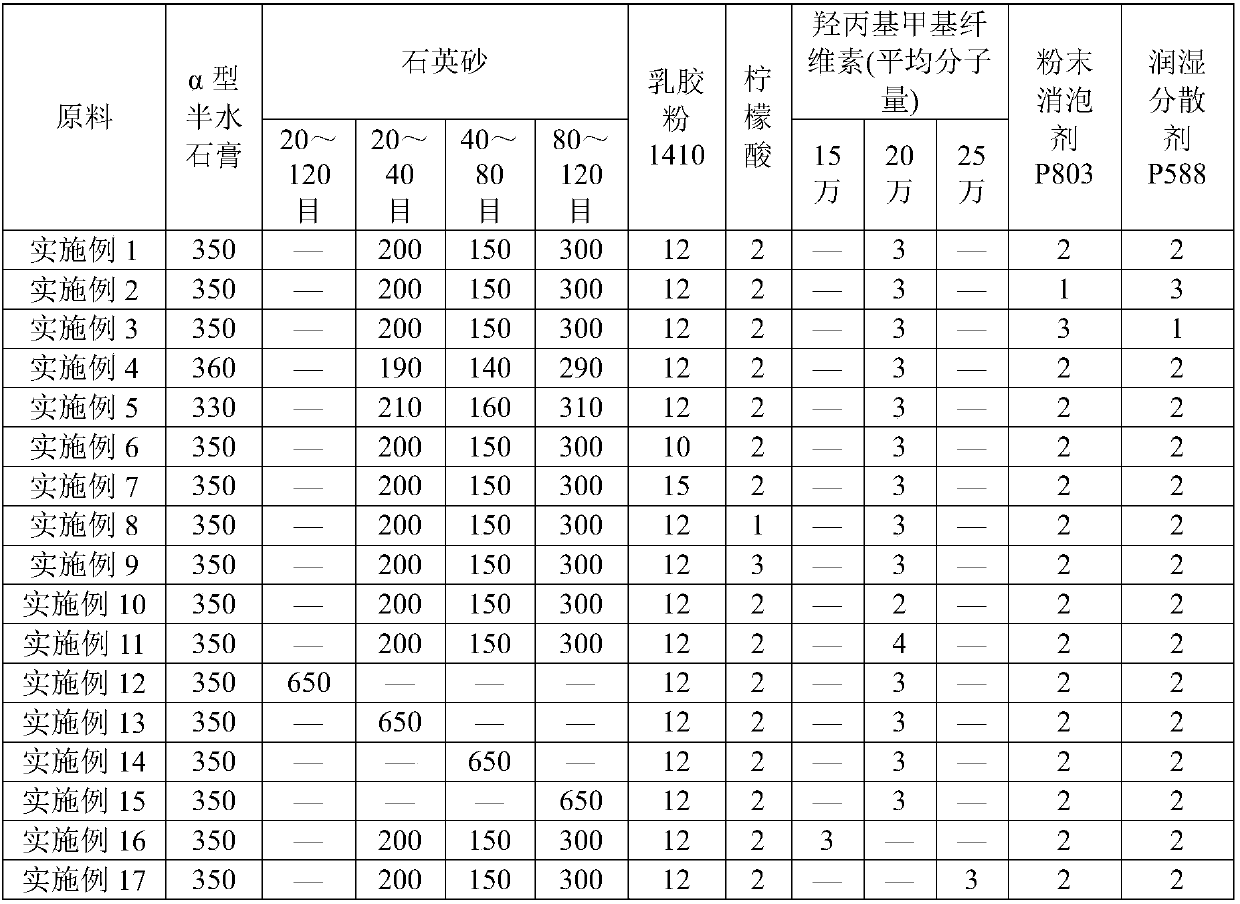

Tile adhesive

InactiveCN109626930AImprove performanceGood insulation and sound insulation propertiesFreeze thawingAdhesive

The invention relates to a tile adhesive. The tile adhesive is characterized by comprising, by mass, 330-360 parts of alpha-type semi-hydrated gypsum, 620-680 parts of quartz sand, 10-15 parts of latex powder, 1-3 parts of citric acid, 2-4 parts of hydroxypropyl methyl cellulose, 1-3 parts of a defoaming agent and 1-3 parts of a wetting dispersant. The tile adhesive is prepared with the alpha-typesemi-hydrated gypsum which replaces cement, and can be well attached to the surfaces of a plurality of base materials hard to attach; the bonding strength is still very good under the condition of soaking in water, high temperate or freeze-thaw action.

Owner:中北国泰建设集团有限公司

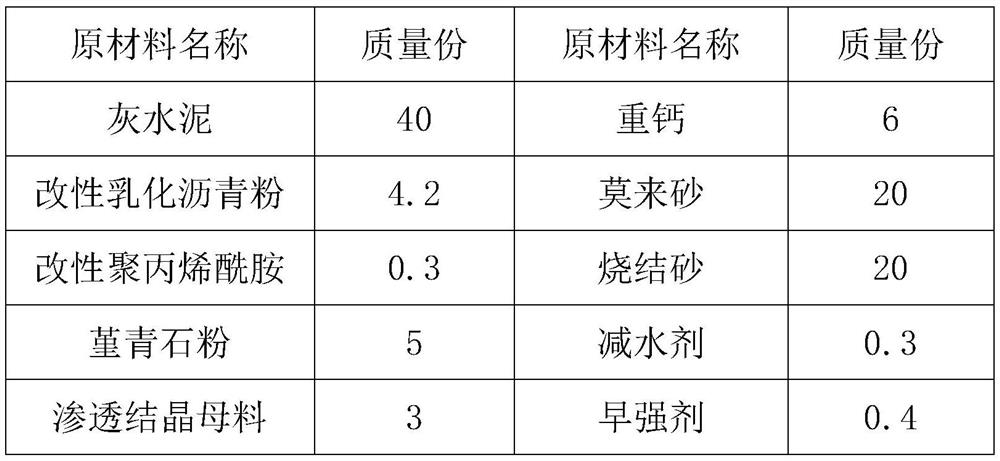

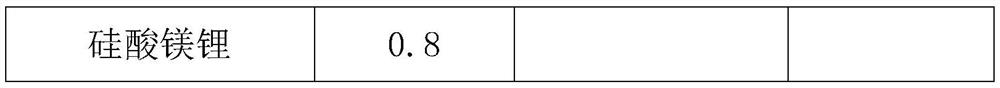

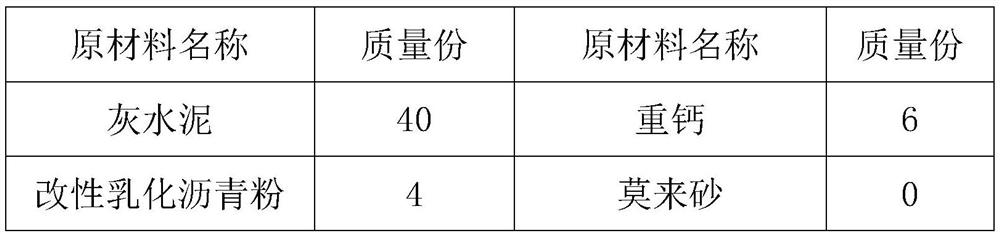

Easy plaster and additive thereof

ActiveCN114634323AHigh bonding strengthPossess impermeabilitySolid waste managementSilicic acidBitumen emulsion

The invention discloses easy plaster and an additive thereof, and relates to the technical field of building materials, and the easy plaster comprises the following components: ash cement, modified emulsified asphalt powder, modified polyacrylamide, cordierite powder, capillary crystalline master batch, magnesium lithium silicate, coarse whiting, 50-80-mesh mullite sand, 70-140-mesh sintered sand, a water reducing agent and an early strength agent. According to the invention, the easy plaster is subjected to a polymer modification technology and an asphalt modification technology, proper functional fillers and additives are selected, technical improvement is carried out aiming at the defects of various easy plaster products, and the prepared finished product has the following comprehensive characteristics: 1) the easy plaster has the effects of impermeability, bonding, water resistance, leakage stoppage and the like; 2) the flexible performance is excellent, the influence of deformation, settlement and the like can be endured, and cracking is avoided; 3) the shrinkage is low, no shrinkage crack is generated after construction, and the quality is stable; (4) the bonding strength is high, and the anti-sliding performance is good; 5) the weather resistance and the aging resistance are good; and 6) the unit area consumption is less, and the method is more environment-friendly and economical.

Owner:WEIFANG HONGYUAN WATERPROOF MATERIAL

A resin concrete sleeper

Owner:威海瑞合铁路轨枕有限公司

A road pavement base structure

ActiveCN108570899BNo shrinkage cracksImprove water stabilityIn situ pavingsRoad engineeringArchitectural engineering

The objective of the invention is to provide a pavement base structure of a road. The pavement base structure comprises a base and a subbase. The pavement base structure is characterized in that the subbase comprises, by mass, 2 to 7.5% of a PCSB curing agent, 15 to 28% of waste asphalt powder, 35 to 50% of fine aggregate and 25 to 40% of coarse aggregate (summing to 100%); and the base comprises,by mass, 2.5 to 8% of the PCSB curing agent, 18 to 30% of waste asphalt powder, 35 to 50% of fine aggregate and 25 to 40% of coarse aggregate (summing to 100%). The pavement base structure can reduceshrinkage cracks, improve the quality of a pavement base and lower engineering cost for the road.

Owner:武汉市江夏路桥工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com