Easy plaster and additive thereof

A technology of benefiting cement and additives, applied in the field of building materials, can solve the problems of poor aging resistance, low bonding strength, insufficient bonding strength, etc., and achieve good weather resistance and aging resistance, good anti-slip performance, and flexibility. excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Raw material name Mass portions Raw material name Mass portions Grey cement 40 Heavy calcium 6 Modified emulsified asphalt powder 4 Moray sand 20 Modified polyacrylamide 0.4 Sintered sand 20 Iolite powder 5 Water reducer 0.3 Penetrate crystallized masterbatch 3 Early strength agent 0.3 Lithium magnesium silicate 1

[0032] The preparation method includes the following steps:

[0033] (1) Put cement, iolite powder, heavy calcium and crystalline masterbatch into the gravityless mixer and mix for 10 minutes.

[0034] (2) The modified emulsified asphalt powder, modified polyacrylamide, magnesium lithium silicate, and moray sand are successively put into the gravity-free mixer and mixed for 10 minutes.

[0035] (3) Add sintered sand, water reducer and early strength agent to the gravity-free mixer at a time and mix for 10 minutes.

[0036] (4) Put the powder at the bottom of the mixing tank, put it out and put it back i...

Embodiment 2

[0039] Raw material name Mass portions Raw material name Mass portions Grey cement 41 Heavy calcium 7 Modified emulsified asphalt powder 3 Moray sand 21 Modified polyacrylamide 0.4 Sintered sand 21 Iolite powder 3 Water reducer 0.3 Penetrate crystallized masterbatch 2 Early strength agent 0.3 Lithium magnesium silicate 1

[0040] The preparation method includes the following steps:

[0041] (1) Put cement, iolite powder, heavy calcium and crystalline masterbatch into the gravityless mixer and mix for 10 minutes.

[0042] (2) The modified emulsified asphalt powder, modified polyacrylamide, magnesium lithium silicate, and moray sand are successively put into the gravity-free mixer and mixed for 10 minutes.

[0043](3) Add sintered sand, water reducer and early strength agent to the gravity-free mixer at a time and mix for 10 minutes.

[0044] (4) Put the powder at the bottom of the mixing tank, put it out and put it back in...

Embodiment 3

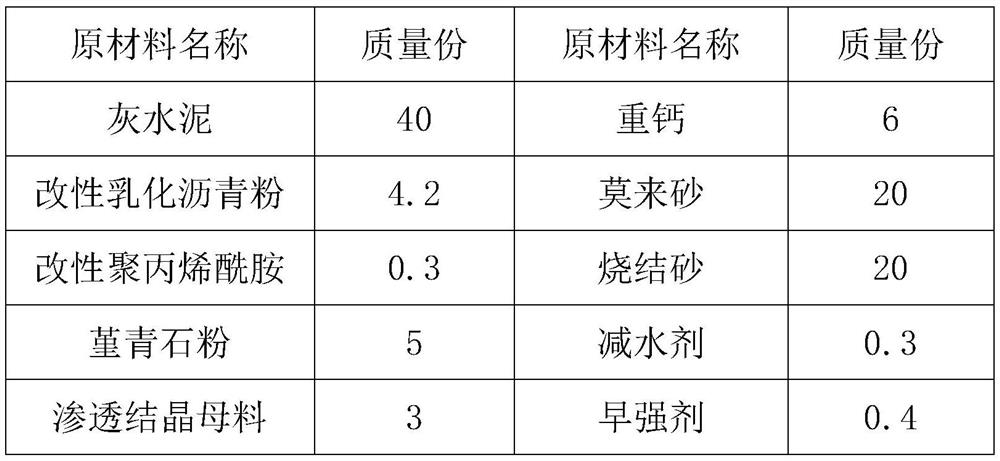

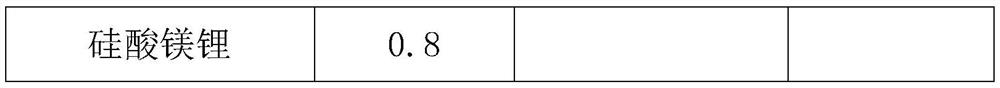

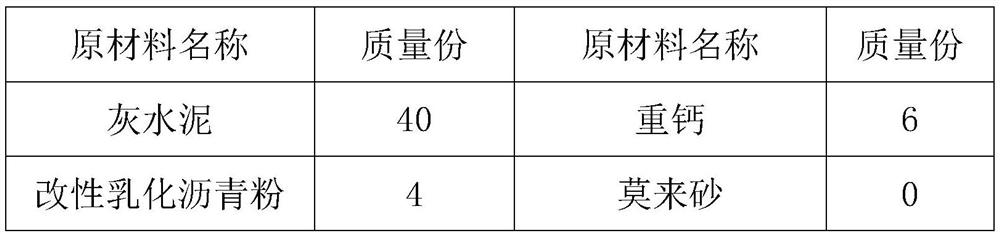

[0047]

[0048]

[0049] The preparation method includes the following steps:

[0050] (1) Put cement, iolite powder, heavy calcium and crystalline masterbatch into the gravityless mixer and mix for 10 minutes.

[0051] (2) The modified emulsified asphalt powder, modified polyacrylamide, magnesium lithium silicate, and moray sand are successively put into the gravity-free mixer and mixed for 10 minutes.

[0052] (3) Add sintered sand, water reducer and early strength agent to the gravity-free mixer at a time and mix for 10 minutes.

[0053] (4) Put the powder at the bottom of the mixing tank, put it out and put it back into the gravityless mixer, and continue to stir for 5 minutes;

[0054] (5) Discharge, observe that the powder is uniform, and the appearance is no impurities, no agglomerated powder, then continue to pack.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com