Tile adhesive

A tile adhesive and defoaming agent technology, applied in the field of tile adhesives, to achieve the effect of ensuring tolerance, good thermal insulation and sound insulation characteristics, and good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

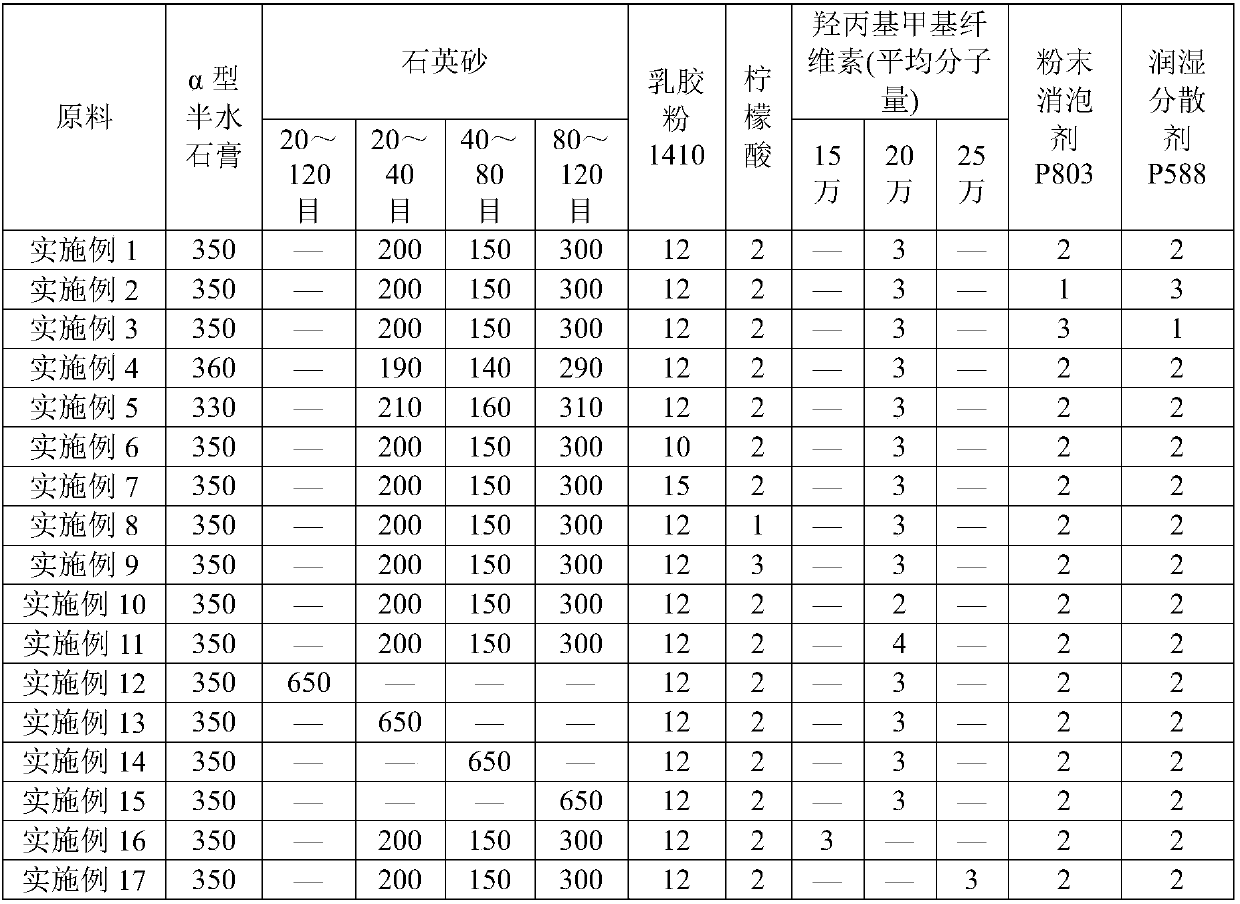

Examples

Embodiment 18

[0028] The difference from Example 1 is that the latex powder 1410 is replaced by the latex powder prepared by the following method: adjustment contains cetyltrimethylammonium bromide 0.9Kg, azobisisobutylamidine hydrochloride 0.5Kg and The pH value of the mixture of 280Kg of deionized water is 7.0, add 20Kg of styrene and 1.5Kg of methacryloxypropyltrimethoxysilane and pre-emulsify, stir the pre-emulsion in a nitrogen atmosphere and raise the temperature to 60°C and keep it warm React for 6 hours; lower to room temperature and adjust the pH value to 3.0, add 17.5Kg of tetraethyl orthosilicate, stir for 12 hours, and leave to age for 36 hours; add 22.5Kg of an aqueous solution of polyvinyl alcohol with a concentration of 5% by weight and mix Uniform, spray-dried to obtain latex powder.

Embodiment 19

[0030] The difference from Example 1 is that the latex powder 1410 is replaced by the latex powder prepared by the following method: adjustment contains cetyltrimethylammonium bromide 1.2Kg, azobisisobutylamidine hydrochloride 0.4Kg and The pH value of the mixture of 290Kg of deionized water is 6.9, add 17.5Kg of styrene and 2Kg of methacryloxypropyltrimethoxysilane and pre-emulsify, stir the pre-emulsion in a nitrogen atmosphere and raise the temperature to 65°C and keep it warm React for 5.5 hours; lower to room temperature and adjust the pH value to 2.9, add 20Kg of tetraethyl orthosilicate, stir for 24 hours, and leave to age for 42 hours; add 25Kg of an aqueous solution of polyvinyl alcohol with a concentration of 1% by weight and mix well , to obtain latex powder by spray drying.

Embodiment 20

[0032] The difference from Example 1 is that the latex powder 1410 is replaced by the latex powder prepared by the following method: adjustment contains cetyltrimethylammonium bromide 1.5Kg, azobisisobutylamidine hydrochloride 0.3Kg and The pH value of the mixed solution of 300Kg of deionized water is 7.1, add 15Kg of styrene and 1.75Kg of methacryloxypropyltrimethoxysilane and pre-emulsify, stir the pre-emulsion in a nitrogen atmosphere and raise the temperature to 70°C and keep it warm React for 5 hours; lower to room temperature and adjust the pH value to 3.1, add 15Kg of tetraethyl orthosilicate, stir for 18 hours, and leave to age for 48 hours; add 24Kg of an aqueous solution of polyvinyl alcohol with a concentration of 10% by weight and mix well, Latex powder was obtained by spray drying.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com