Gypsum-based self-leveling mortar and preparation method thereof

A self-leveling mortar and gypsum-based technology, which is applied in the field of building materials, can solve the problems of restricting the use function and leakage of the roof waterproof layer, and achieve the effects of good thermal insulation and sound insulation characteristics, high efficiency, and fast setting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

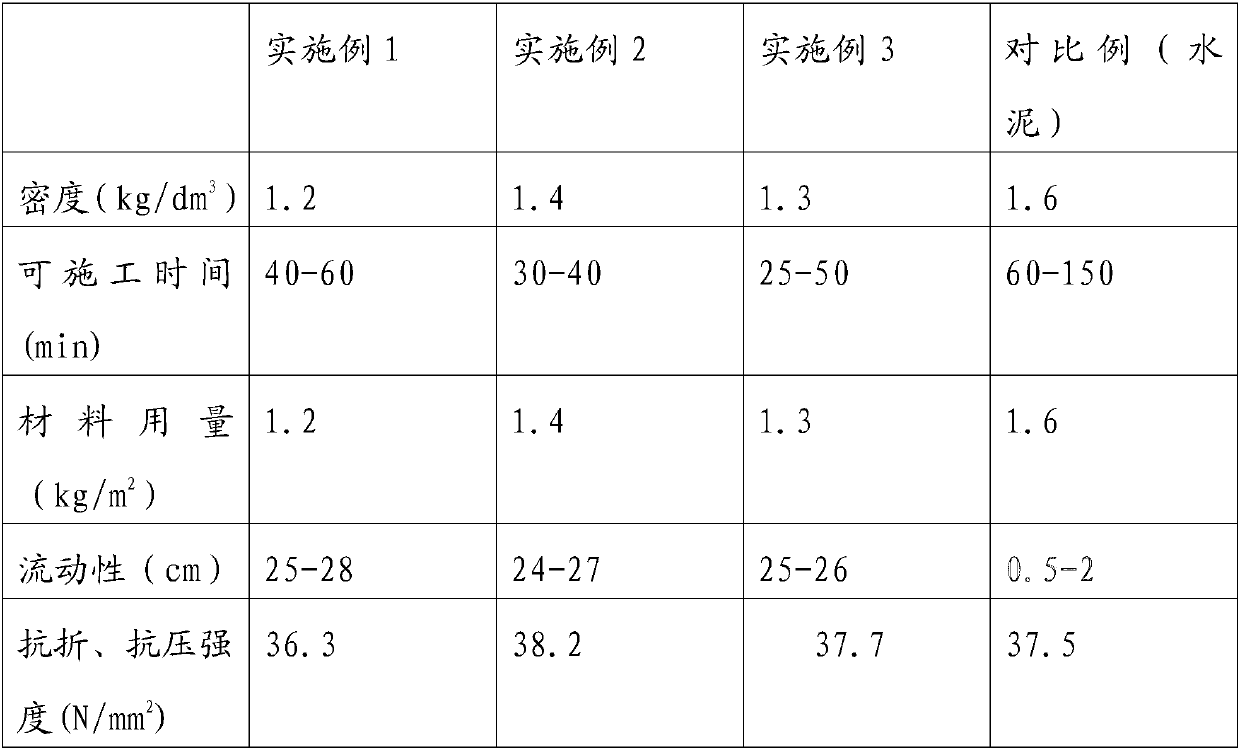

Embodiment 1

[0033] A gypsum-based self-leveling mortar, including the following components: 40 kg of anhydrite, 4 kg of cement, 20 kg of 40-mesh quartz sand, 20 kg of 80-mesh quartz sand, 0.06 kg of retarder, 0.06 kg of water reducing agent, water retention agent 0.08 kg, 0.05 kg of defoamer, 2 kg of redispersible rubber powder. During preparation, each component is weighed and mixed according to the proportion to obtain a gypsum-based self-leveling mortar.

Embodiment 2

[0035] A gypsum-based self-leveling mortar, including the following components: 60 kg of anhydrite, 6 kg of cement, 30 kg of 80-mesh quartz sand, 30 kg of 120-mesh quartz sand, 0.10 kg of retarder, 0.08 kg of water reducing agent, and water retaining agent 0.10 kg, 0.08 kg of defoamer, 3 kg of redispersible rubber powder. During preparation, each component is weighed and mixed according to the proportion to obtain a gypsum-based self-leveling mortar.

Embodiment 3

[0037] A gypsum-based self-leveling mortar, including the following components: 50 kg of anhydrite, 5 kg of cement, 25 kg of 60-mesh quartz sand, 25 kg of 100-mesh quartz sand, 0.08 kg of retarder, 0.07 kg of water reducing agent, and water retaining agent 0.09 kg, 0.06 kg of defoamer, 2.5 kg of redispersible rubber powder. During preparation, each component is weighed and mixed according to the proportion to obtain a gypsum-based self-leveling mortar.

[0038] The gypsum-based self-leveling mortar of the invention is simple to use. When in use, the surface of the object to be used can be treated and used directly. The gypsum-based self-leveling mortar is mixed with water and then applied to the surface. For example, the ground is treated and directly used on the ground.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com