Thin-walled centrifugal concrete pole manufacture method

A manufacturing method and technology of cement poles, applied in the fields of cement light poles, cement communication poles, cement poles, and cement pipe piles, can solve the problems of large shrinkage deformation, affecting the overall strength of thin-walled cement poles, and high cement content. , to achieve the effect of ensuring the overall strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

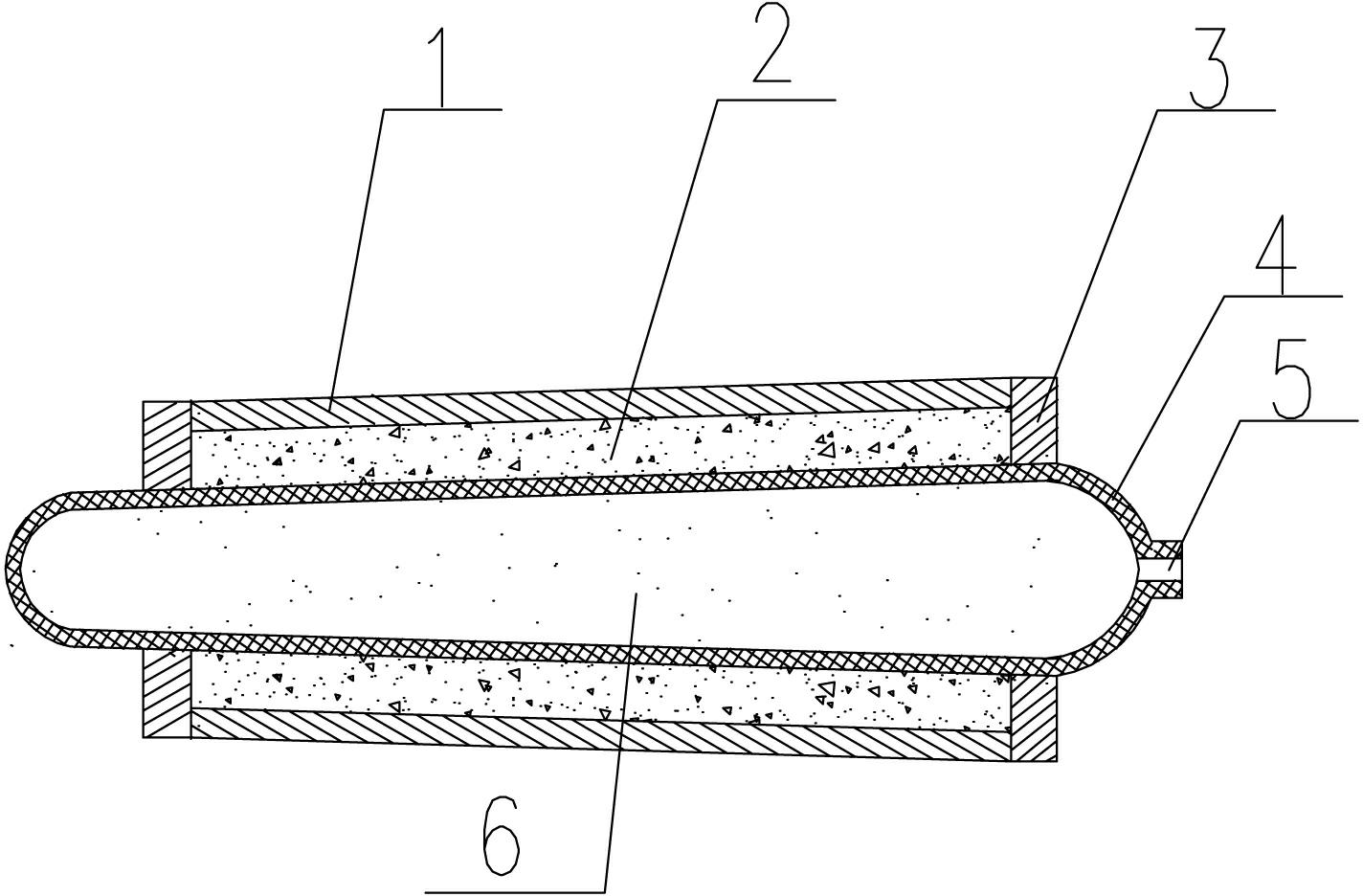

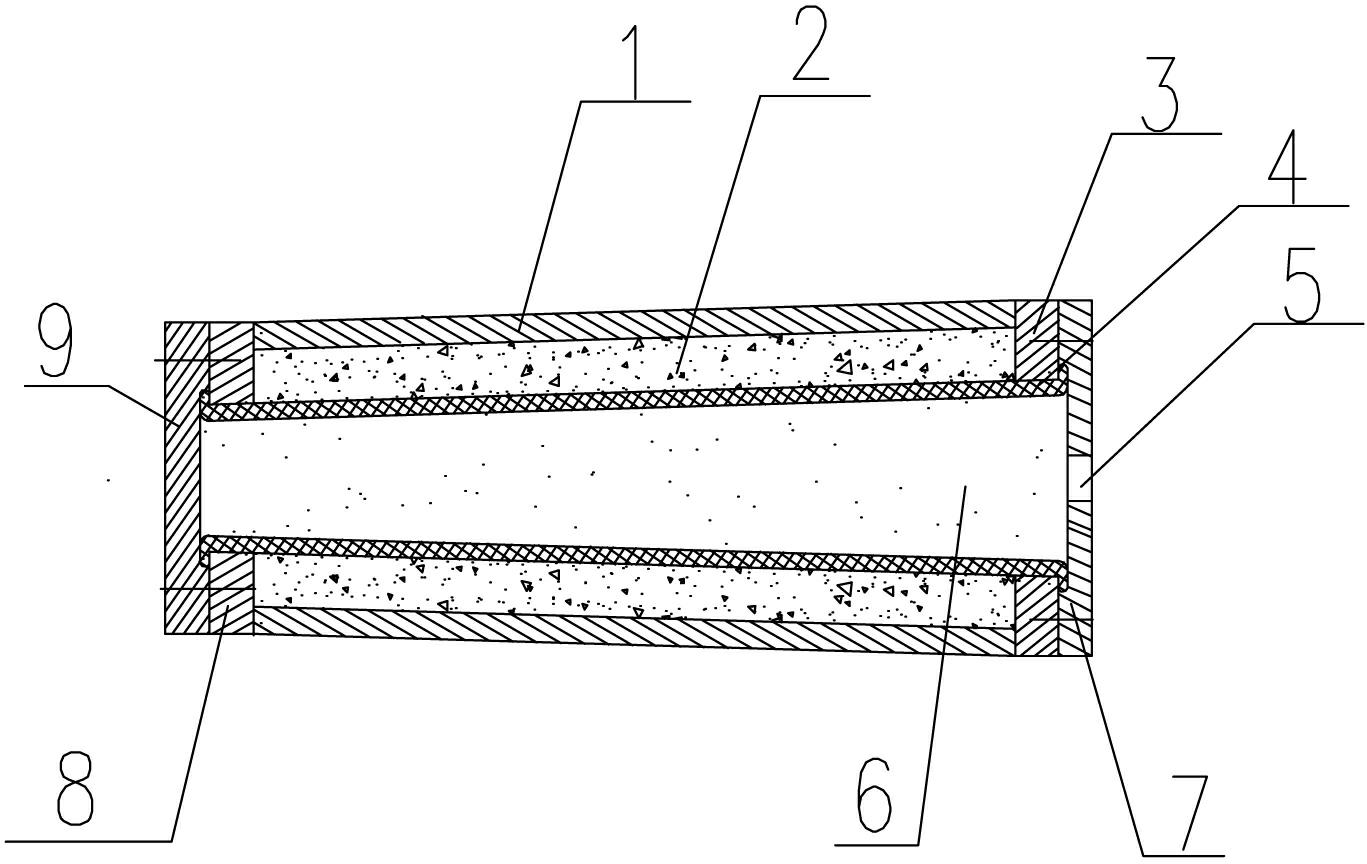

[0021] Such as figure 2 As shown, as an embodiment, the soft pressurized membrane 4 of the present invention is composed of a soft pressurized membrane sealing cover II7 with a medium injection port 5 at one end, and a conical tube or a circular tubular structure with an opening at the other end. One end of the body 1 is provided with a soft pressurized membrane sealing cover I9, and the opening end of the tapered tube or circular tubular soft pressurized membrane is sealed by the soft pressurized membrane sealing cover I9 with the end cover I8 on the centrifugal mold body 1 through bolts To connect, after the soft pressurized membrane of the tapered tube or circular tubular structure has the pressurized membrane seal cover II7 with the medium injection port 5 and the other end cover II3 on the centrifugal mold body are fixedly connected by bolts, the When the pressurized medium 6 is injected into the soft pressurized film 4 of the conical or circular tubular structure, the...

Embodiment 2

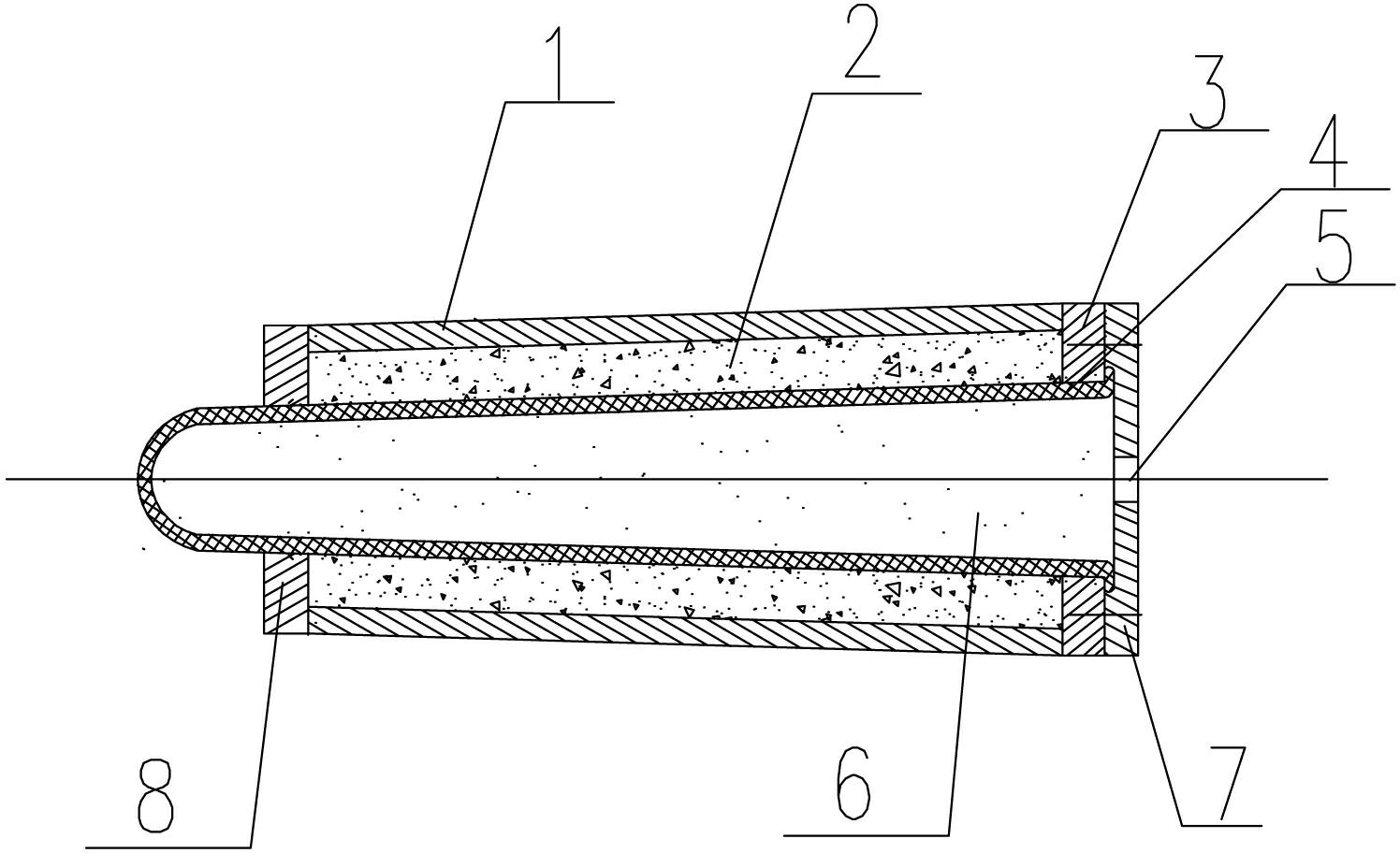

[0023] Such as image 3 As shown, as an embodiment, the soft pressurized membrane of the present invention is composed of a soft pressurized membrane sealing cover 7 with a medium injection port 5 at one end, and a barrel-shaped structure with an arc-shaped head at the other end. The pressurized film sealing cover 7 end with the medium injection port 5 is fixedly connected with the end cover II at one end of the centrifugal mold body 1 through bolts, and the arc-shaped end of the sealing head extends out of the other end cover I of the centrifugal mold body 1. When the pressurized medium 6 is injected into the soft pressurized film 4 of the barrel-shaped structure, the barrel-shaped soft pressurized film with an arc-shaped head and the pressurized film seal cover with a medium injection port together form an injection pressurized Closed cavity for media. The soft pressurized membrane 4 of this structure is relatively convenient to operate, and its pressurized pressure is 0.2-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com