Multifunctional cutting machine

A slitting machine and multi-functional technology, which is applied in metal processing and other fields, can solve the problems of non-interchangeability and single function, and achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the embodiments and with reference to the accompanying drawings.

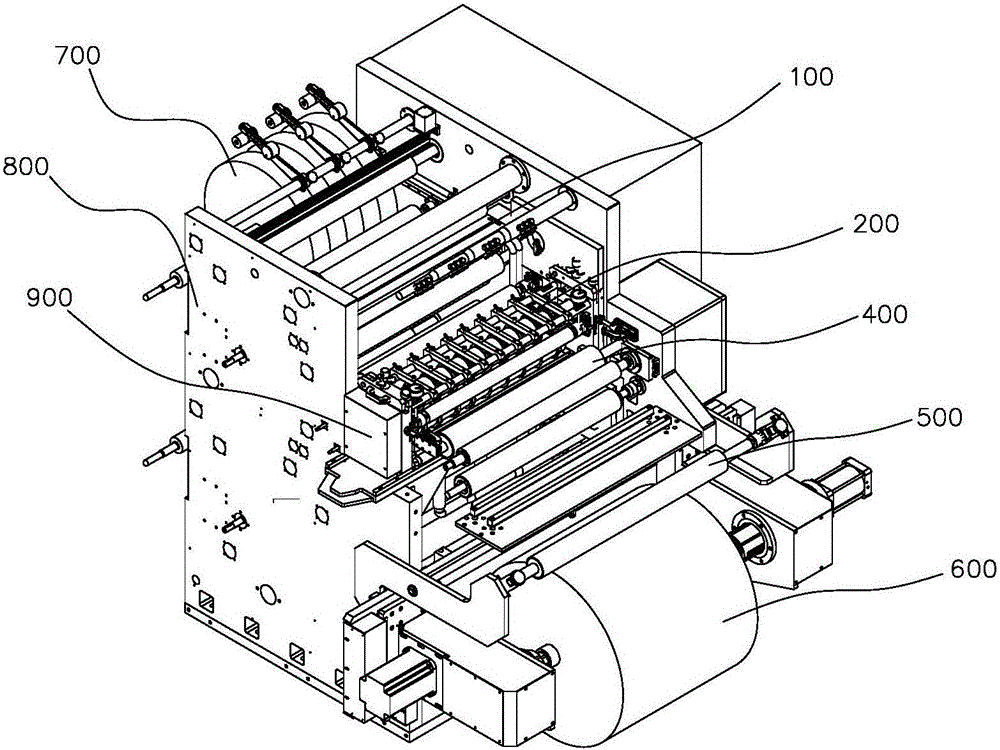

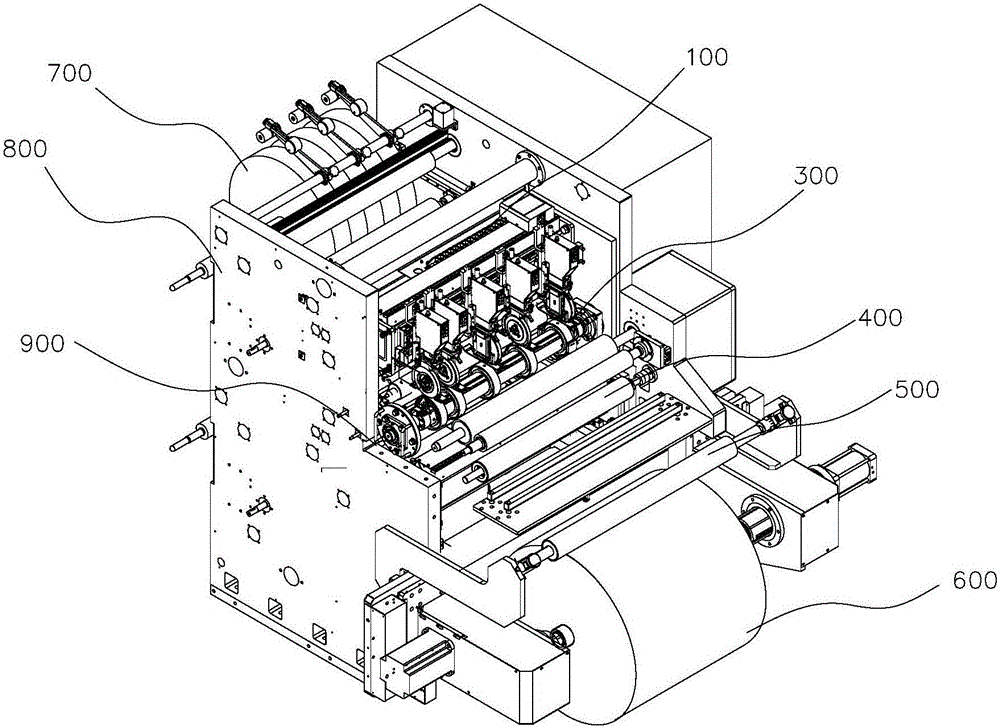

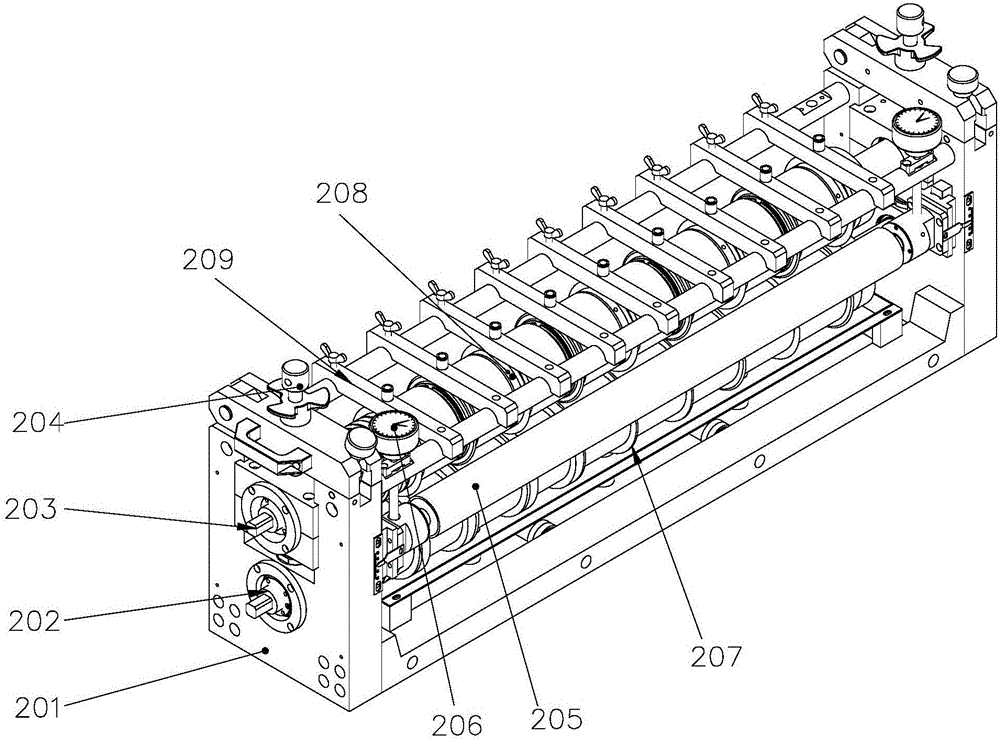

[0020] A multifunctional cutting machine, refer to Figure 1 to Figure 2 , including a frame 800, the front end of the frame 800 is provided with an unwinding module 600, the rear end of the frame 800 is provided with a rewinding module 700, and the middle part of the frame 800 is also provided with a knife holder installation port 900, the Knife rest mounting port 900 is detachably installed with mechanical circular knife knife rest 200 (refer to figure 1 ) or automatic tool holder 300 (refer to figure 2 ), the material on the unwinding module 600 is cut into a small material by the round knife on the mechanical round knife knife rest 200 or the row knife on the automatic knife row knife rest 300, and then by a plurality of winding rollers on the winding module 700 Roll up.

[0021] This multi-functional slitting mac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com