Labor-saving bicycle

A bicycle and axle technology, which is applied to vehicle components, vehicle gearboxes, wheel transmissions, etc., can solve the problems of inconspicuousness and laborious riding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

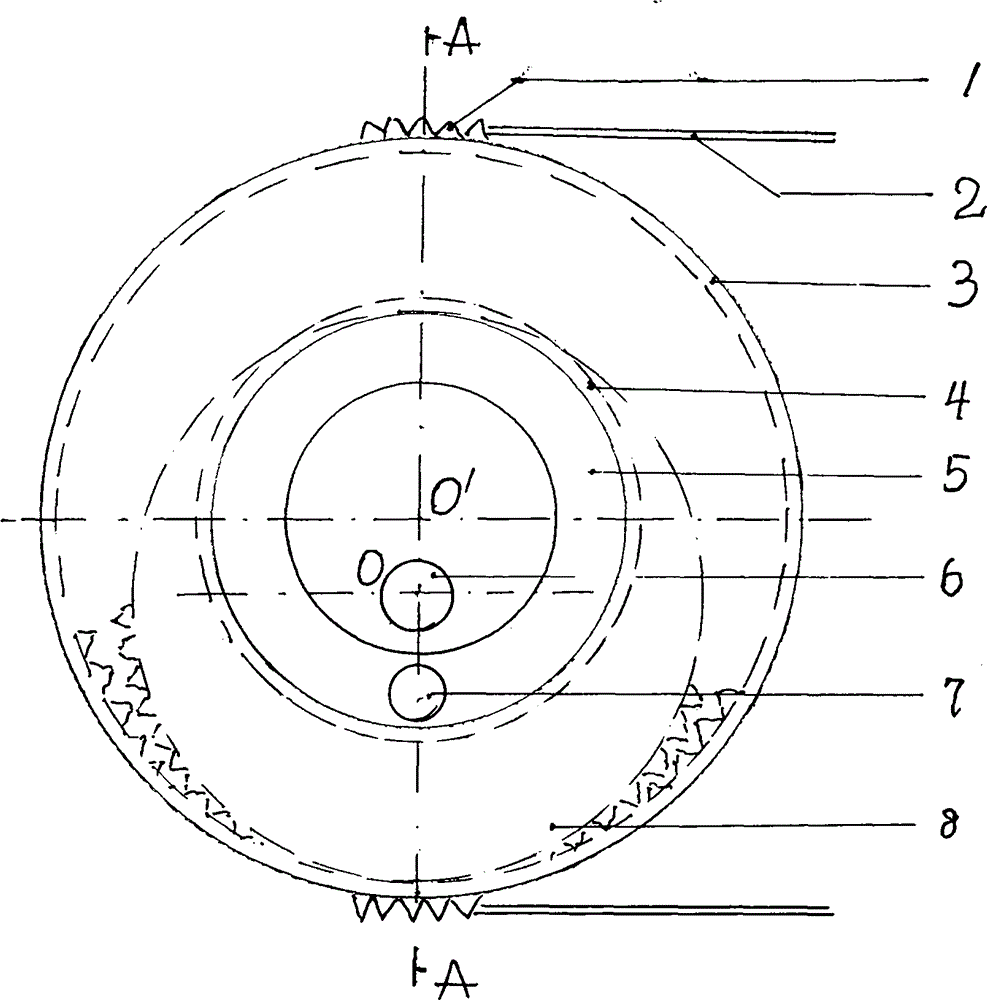

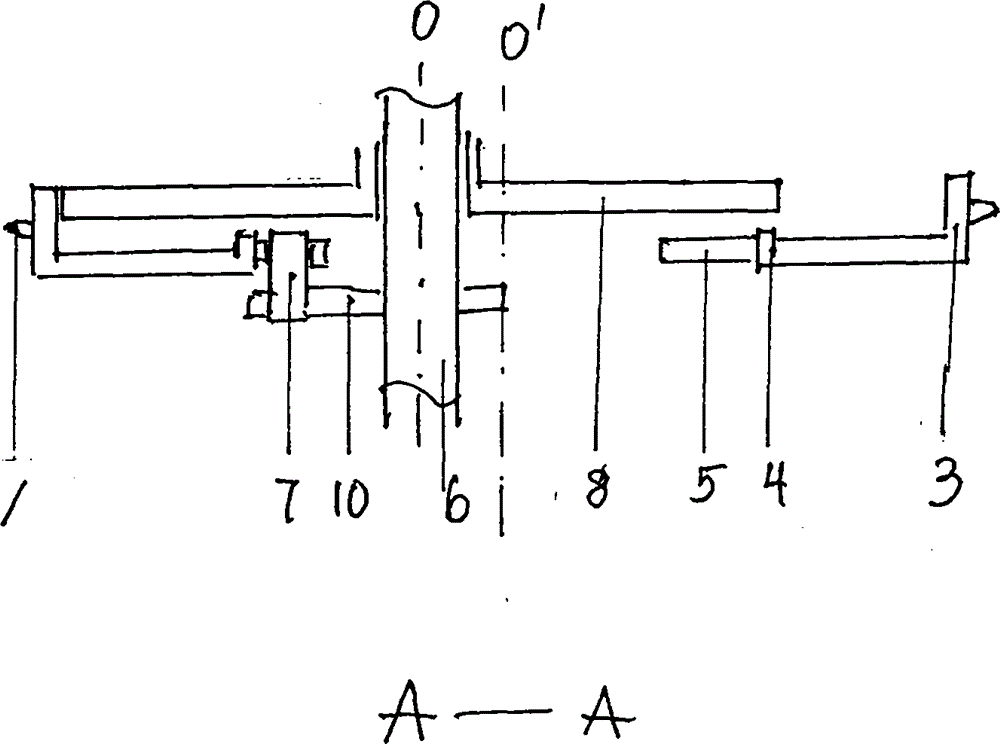

[0022] Specific implementation mode one, combining figure 1 figure 2 Explanation: The hub gear 8 is installed on the hub, and an overrunning clutch is installed between the hub gear 8 and the hub. The inner side of the double-ring gear outer ring 3 has gear teeth. The inboard of double ring gear inner ring 4 is equipped with fulcrum ring 5, bearing is arranged between fulcrum ring 5 and double ring gear inner ring 4, and hole is arranged on the fulcrum ring 5. Support 10 is fixedly installed on the axle 6, and fulcrum shaft 7 is installed on the support 10, and fulcrum shaft 7 penetrates in the hole of fulcrum ring 5, and fulcrum shaft 7 can rotate in the hole of fulcrum ring 5. The gear teeth on the inner side of the double ring gear outer ring 3 are meshed with the gear teeth of the hub gear 8 . A cog 1 is arranged on the double ring gear, and a chain 2 is installed on the cog 1.

specific Embodiment approach 2

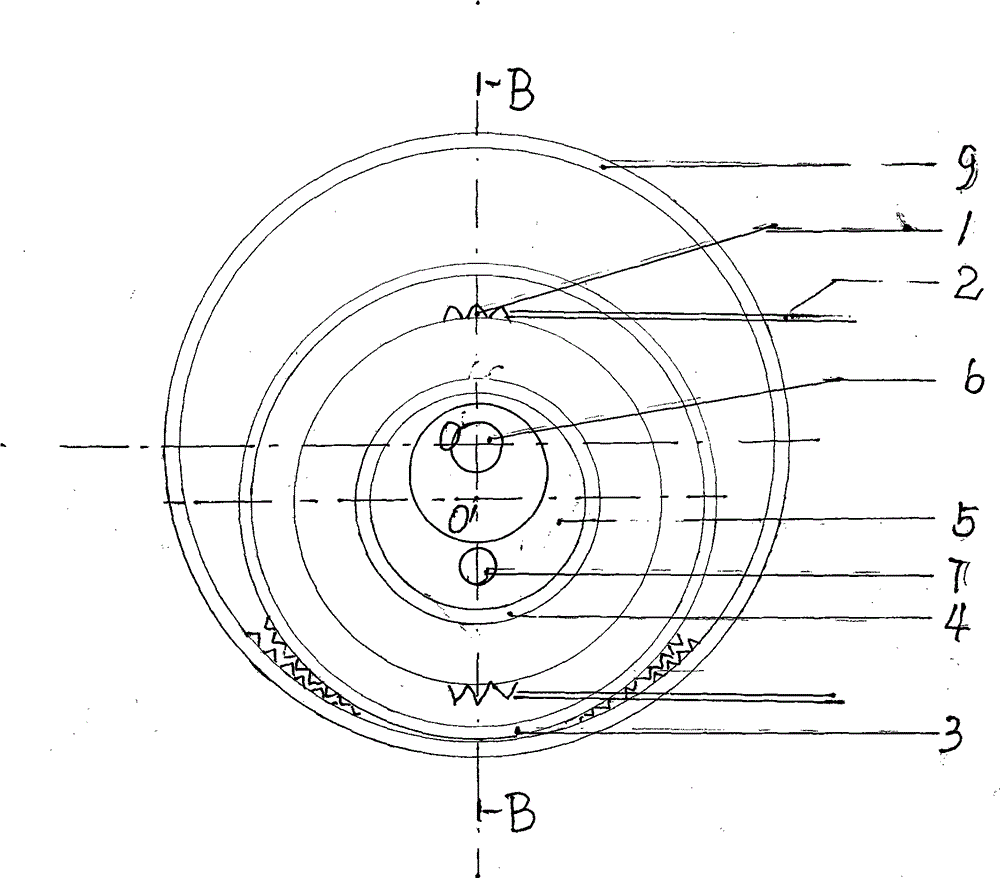

[0023] Specific implementation mode two, combining image 3 Figure 4 Explanation: the hub gear ring 9 is installed on the hub, and an overrunning clutch is arranged between the hub gear ring 9 and the hub. There are gear teeth on the outside of the double ring gear outer ring 3. The inboard of double ring gear inner ring 4 is equipped with fulcrum ring 5, bearing is arranged between fulcrum ring 5 and double ring gear inner ring 4, and hole is arranged on the fulcrum ring 5. Support 10 is fixedly installed on the axle 6, and fulcrum shaft 7 is installed on the support 10, and fulcrum shaft 7 penetrates in the hole of fulcrum ring 5, and fulcrum shaft 7 can rotate in the hole of fulcrum ring 5. The gear teeth on the outside of the double ring gear outer ring 3 are meshed with the gear teeth on the hub gear ring 9 . A cog 1 is arranged on the double ring gear, and a chain 2 is installed on the cog 1.

specific Embodiment approach 3

[0024] Specific implementation mode three, combining Figure 5 Figure 6 Explanation: The hub gear 8 is installed on the hub, and an overrunning clutch is installed between the hub gear 8 and the hub. The inner side of the double-ring gear outer ring 3 has gear teeth. An eccentric bearing 11 is installed on the inner side of the double-ring gear inner ring 4; an eccentric block 12 is fixedly installed on the axle 6, and the eccentric block 12 and the axle 6 together form a fulcrum shaft, that is, the fulcrum shaft and the axle shaft are integrated, and the axial direction of the integrated fulcrum shaft The center line and the axial center line of the axle shaft 6 do not coincide, and this integral fulcrum shaft passes through the shaft hole of the eccentric bearing 11 and can rotate in the shaft hole. The gear teeth on the inner side of the double ring gear outer ring 3 are meshed with the gear teeth of the hub gear 8 . A cog 1 is arranged on the double ring gear, and a ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com