Pre-shell extraction mechanism for straight-pull bolt type sporting rifle

A technology for sports rifles and straight-pull bolts, which is applied in the field of firearms and can solve problems such as the inability to design a pre-extraction mechanism, large extraction resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the purpose, technical solution and creative characteristics of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

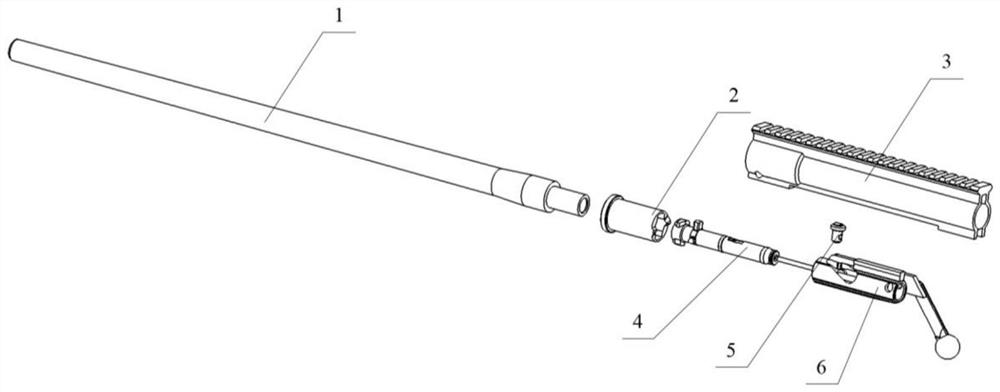

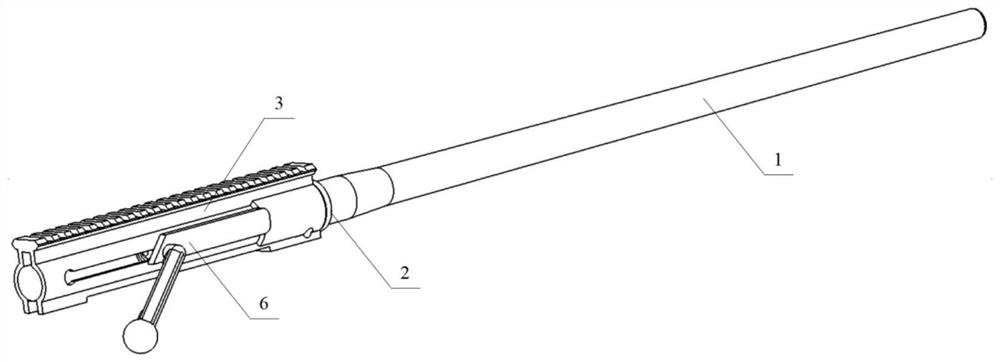

[0023] Such as figure 1 As shown, a pre-extraction mechanism for a straight-pull action rifle according to the present invention includes a barrel 1 , a joint 2 , a casing 3 , a action 4 , an opening and closing guide post 5 , and a action frame 6 . After its assembly is completed as figure 2 shown.

[0024] Such as figure 2 As shown, the gun barrel 1, the joint cover 2, and the casing 3 are fixed together and cannot move between each other, and the bolt 4, the opening and closing lock guide post 5, and the bolt frame 6 are moving parts.

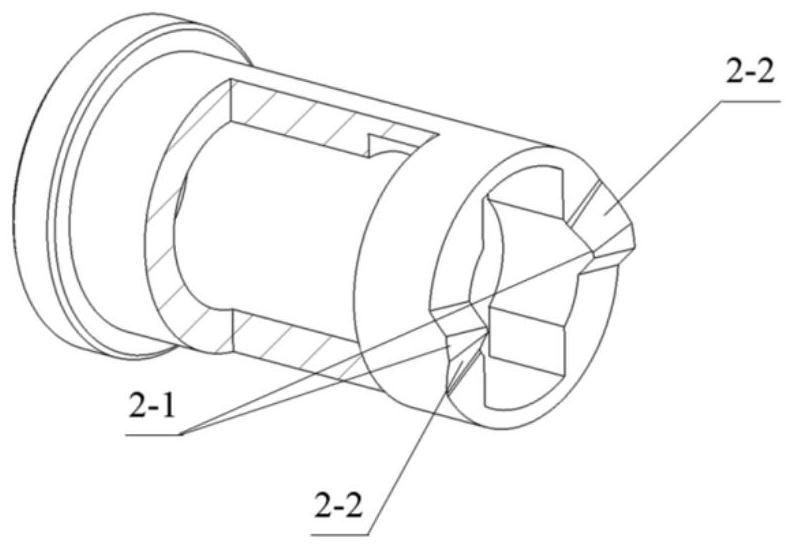

[0025] Such as image 3 , Figure 4 As shown in the figure, to the left is the front, and to the right is the rear. The rear end surface of the joint sleeve 2 is provided with a pair of start-up protrusion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com