Automatic quantification filling machine separator device

A filling machine and separator technology, applied in the field of automatic quantitative filling machine separator devices, can solve the problems of instability, inaccurate food quantity, inaccurate filling quantity, etc., and achieves convenient and safe installation, scientific design and structure. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The following examples illustrate the present invention in more detail, but are not limited to the following examples as long as it falls within the scope of the present invention.

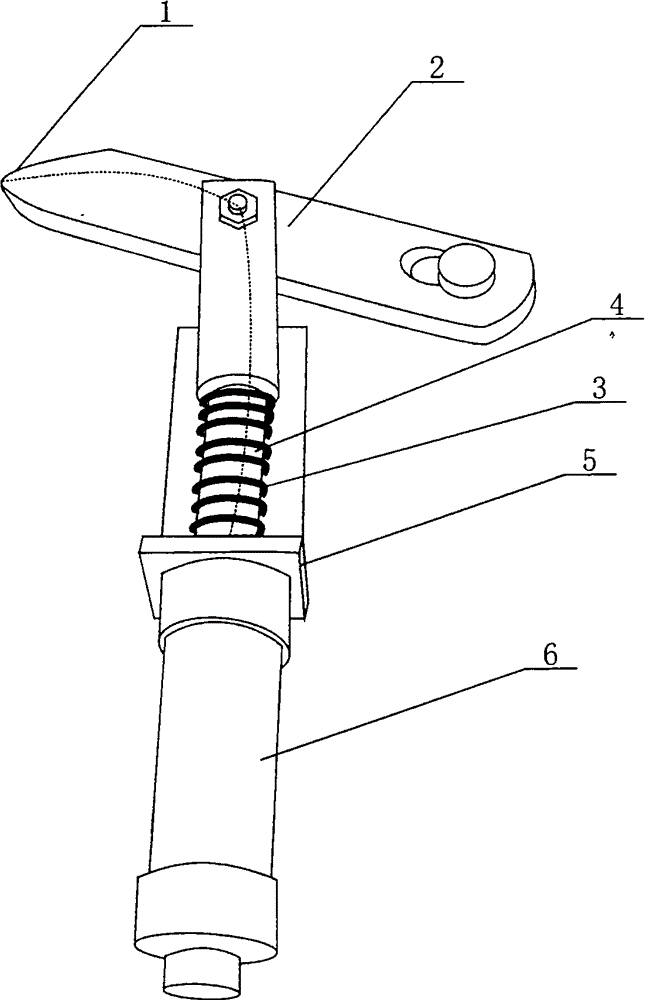

[0014] An automatic quantitative filling machine separator device is composed of a separating nozzle (1), a separating joint (2), a spring (3), a connecting rod (4), a fixing plate (5) and a handle (6). The fixed plate (5) is fixed on the filling machine, one end of the fixed plate (5) is connected with a handle (6), one end is connected with the connecting rod (4), the spring (3) is fixed on the periphery of the connecting rod (4), and the joint is separated (2) is connected with the separation nozzle (1), and the connecting rod (4) passes through the inner hole of the separation joint (2) and is connected with the separation nozzle (1).

[0015] When working: turn on the power and start the filling machine. When the separation nozzle (1) collides with the parts on the filling machine, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com